7 Preventive Maintenance Best Practices for HVAC in 2025

- Putnam Mechanical

- Aug 24, 2025

- 16 min read

In the demanding commercial landscape, the reliability of your HVAC and refrigeration systems isn't just about comfort, it's about business continuity. An unexpected breakdown can lead to lost inventory, unhappy customers, and soaring emergency repair costs. Moving beyond a reactive 'fix-it-when-it-breaks' model is crucial for long-term operational success and financial stability. Adopting robust preventive maintenance best practices transforms your essential systems from a potential liability into a predictable, high-performing asset.

This guide moves beyond basic tune-ups and filter changes to explore seven advanced strategies that leading facility managers use to maximize equipment lifespan, optimize energy consumption, and eliminate unplanned downtime. These aren't just simple checklist items; they are comprehensive methodologies designed to build a resilient and cost-effective maintenance culture. By implementing these sophisticated approaches, you can shift from a state of constant reaction to one of strategic control, ensuring your equipment operates at peak efficiency.

Here, we will detail actionable frameworks that allow you to anticipate failures before they occur, allocate resources more effectively, and align your maintenance efforts directly with your core business objectives. You will learn how to implement proven systems for:

Systematic Management: Leveraging Computerized Maintenance Management Systems (CMMS).

Strategic Prioritization: Focusing efforts with Risk-Based Maintenance (RBM).

Data-Driven Decisions: Using Condition-Based Monitoring and predictive analytics.

Team Empowerment: Engaging all staff through Total Productive Maintenance (TPM).

Function-Focused Strategy: Applying Reliability-Centered Maintenance (RCM) principles.

Performance Measurement: Tracking Key Performance Indicators (KPIs).

Operational Efficiency: Optimizing Maintenance Planning and Scheduling.

Each of these preventive maintenance best practices offers a structured path toward greater operational reliability and significant cost savings.

1. Implementing Computerized Maintenance Management Systems (CMMS)

Moving beyond manual spreadsheets and paper records is the single most impactful step toward a modern maintenance strategy. A Computerized Maintenance Management System (CMMS) is a software solution that centralizes all maintenance information, transforming reactive repairs into a proactive, data-driven operation. It acts as a central nervous system for your maintenance activities, automating scheduling, tracking work orders, managing spare parts inventory, and generating detailed performance reports.

For facility managers overseeing complex commercial HVAC and refrigeration systems, a CMMS is not a luxury; it's a foundational tool for operational excellence. It eliminates guesswork by providing a clear, real-time view of asset health, maintenance history, and resource allocation. This level of organization is crucial for one of the most vital preventive maintenance best practices: consistency. By automating recurring tasks and alerts, a CMMS ensures that critical inspections, cleanings, and part replacements are never missed.

Why Implement a CMMS?

Implementing a CMMS is about gaining control and visibility. For example, Marriott Hotels utilized a CMMS across thousands of properties to standardize maintenance procedures, ensuring every location adhered to the same high standards for guest comfort and safety. Similarly, Boeing reduced unplanned downtime on its manufacturing equipment by 25% by leveraging CMMS data to predict failures before they happened.

The primary benefit is the shift from a "break-fix" model to a predictive one. Instead of reacting to a catastrophic AC failure during a summer heatwave, your CMMS will have already scheduled the necessary coil cleaning, refrigerant check, and fan motor inspection based on manufacturer recommendations and historical performance data. This proactive approach minimizes costly emergency calls, extends equipment lifespan, and optimizes energy consumption.

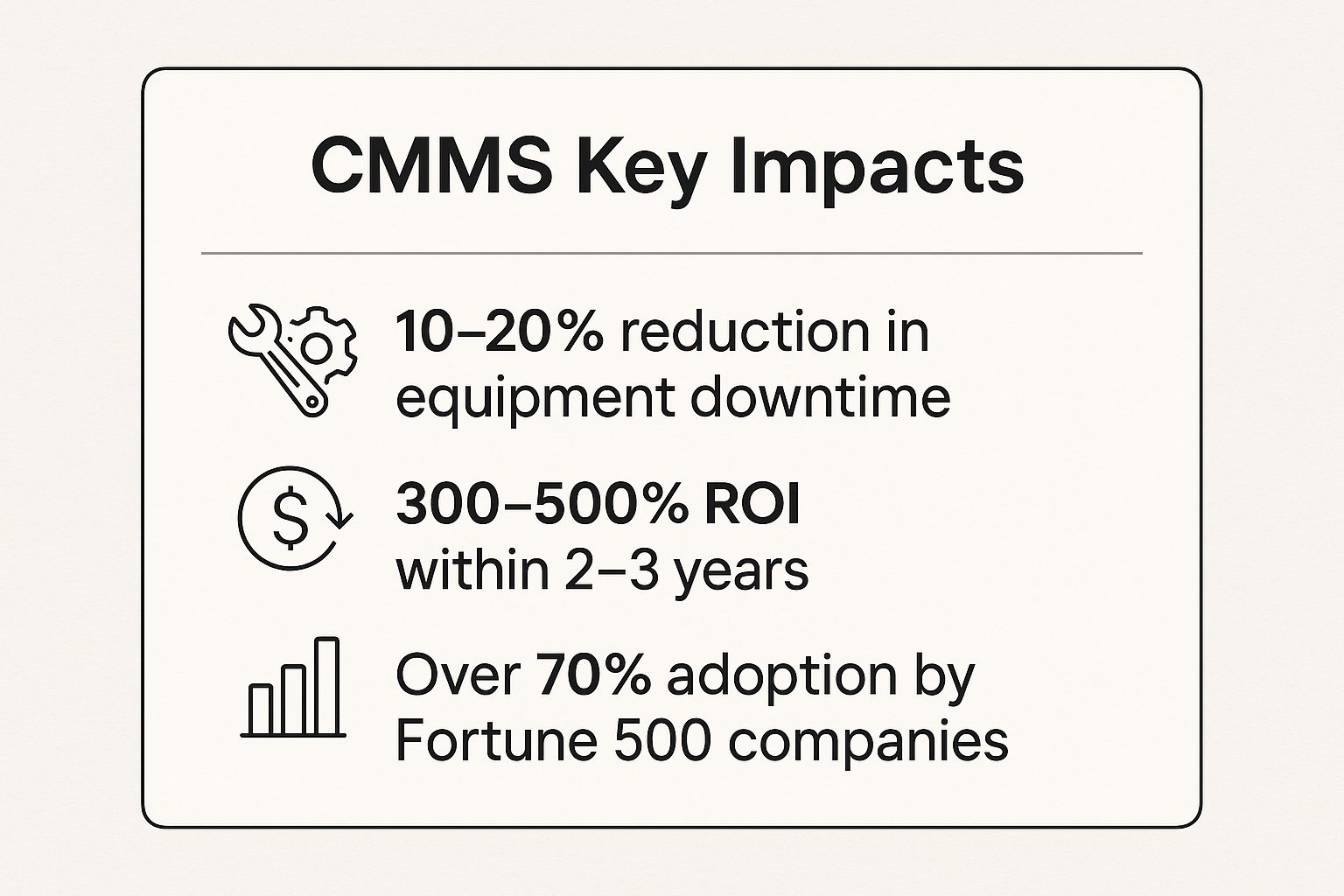

To illustrate the proven impact of these systems, the following infographic highlights key performance indicators from businesses that have successfully integrated a CMMS.

These figures demonstrate that a CMMS is not just an organizational tool, but a significant driver of financial return and operational stability.

Actionable Implementation Tips

To ensure a successful rollout and maximize your return on investment, consider these practical steps:

Start with a Pilot Program: Before a company-wide implementation, test the CMMS in a single department or on a specific set of critical assets. This allows you to refine processes and demonstrate value with a smaller, manageable group.

Prioritize Clean Data Migration: Your CMMS is only as good as the data within it. Ensure all existing asset information, maintenance histories, and parts inventories are accurate and consistently formatted before importing them.

Provide Comprehensive Training: A system is useless if your team doesn’t know how to use it. Invest in thorough training for all users, from technicians to managers, focusing on how the system simplifies their specific daily tasks.

Choose an Integrated System: Select a CMMS that can integrate with your existing enterprise software, such as accounting or building management systems. Popular solutions like UpKeep, Fiix by Rockwell Automation, and IBM Maximo are known for their robust integration capabilities.

2. Adopting a Risk-Based Maintenance (RBM) Strategy

Transitioning from a purely time-based schedule to a more intelligent approach is a hallmark of advanced maintenance. A Risk-Based Maintenance (RBM) strategy prioritizes maintenance resources toward assets whose failure would pose the greatest risk to operations, safety, and finances. It moves beyond a one-size-fits-all schedule, focusing effort where it matters most by evaluating both the probability of an asset failing and the consequences of that failure.

For facility managers responsible for extensive HVAC and refrigeration networks, RBM provides a logical framework for resource allocation. Instead of treating the walk-in freezer at a restaurant and a secondary office AC unit with the same maintenance frequency, RBM ensures the most critical systems receive the most attention. This strategic focus is essential for implementing one of the most effective preventive maintenance best practices: efficiency. By directing skilled technicians and budgets toward high-risk assets, you prevent the most catastrophic and costly failures.

Why Implement an RBM Strategy?

Implementing an RBM strategy is about optimizing resources and minimizing significant business disruptions. For instance, petrochemical giant ExxonMobil applies RBM across its global facilities to prioritize inspections and maintenance on high-pressure systems, drastically reducing the risk of hazardous incidents. Similarly, major airlines like Delta use RBM principles for engine maintenance, focusing on components with higher failure probabilities and safety consequences, which has helped reduce unexpected failures by over 60%.

The core advantage is protecting business continuity. Instead of simply performing routine maintenance on all equipment equally, RBM ensures the refrigeration unit holding thousands of dollars in perishable inventory is inspected more rigorously than a less critical air handler. This risk-based approach helps to proactively manage and prevent costly equipment breakdowns by aligning maintenance efforts with business impact, ensuring operational stability and safeguarding revenue streams.

Actionable Implementation Tips

To effectively integrate an RBM strategy and optimize your maintenance program, consider these practical steps:

Start with Critical Assets: Begin by performing a risk assessment on your most critical equipment. Identify assets where failure would cause significant financial loss, safety hazards, or operational shutdown.

Form a Cross-Functional Team: Involve operations, engineering, and finance teams in the risk assessment process. Their diverse perspectives are crucial for accurately determining the true consequences of a potential failure.

Utilize Historical Data: Use maintenance logs, work order histories, and failure records to accurately estimate the probability of failure for different assets. This data-driven approach validates your risk models.

Regularly Review and Update: Risk is not static. Equipment ages, operational demands change, and new technologies emerge. Re-evaluate your risk assessments annually or whenever a significant operational change occurs.

3. Condition-Based Monitoring and Predictive Analytics

Transitioning from time-based schedules to real-time, data-driven interventions represents the next frontier in maintenance excellence. Condition-based monitoring (CBM) leverages IoT sensors to continuously track critical health parameters of your HVAC and refrigeration systems, such as vibration, temperature, refrigerant pressure, and electrical current. This live data feed, when combined with predictive analytics and machine learning, allows you to detect the earliest signs of potential failure, optimizing maintenance based on actual equipment condition rather than a generic calendar.

This approach transforms maintenance from a scheduled obligation into a strategic response. It's a core component of advanced preventive maintenance best practices because it focuses resources precisely where and when they are needed most. Instead of performing a costly overhaul on a healthy compressor just because the manual says so, CBM tells you the exact moment performance begins to degrade, allowing for a surgical, cost-effective intervention long before a catastrophic failure occurs.

Why Implement Condition-Based Monitoring?

The primary driver for adopting CBM is to maximize asset reliability and minimize operational costs. For instance, Rolls-Royce's TotalCare program uses thousands of sensors to monitor its aircraft engines globally, predicting maintenance needs mid-flight to ensure planes are serviced immediately upon landing, drastically reducing downtime. Similarly, Caterpillar implements CBM on its heavy mining equipment, reducing maintenance costs by up to 35% by addressing issues based on real-world operational stress rather than fixed service hours.

For commercial facilities, this means avoiding a walk-in freezer failure by catching a subtle increase in compressor vibration that indicates bearing wear. It allows you to address the root cause proactively instead of reacting to thousands of dollars in spoiled inventory. This data-first strategy not only prevents failures but also provides invaluable insights into equipment efficiency. For example, by understanding how your commercial refrigeration system performs under different loads, you can optimize its operation and significantly lower energy bills. To dive deeper into specific upkeep strategies, explore our guide on how to keep your commercial refrigerator running at peak performance.

Actionable Implementation Tips

To effectively integrate CBM and predictive analytics into your maintenance program, follow these strategic steps:

Start with Critical Assets: Focus your initial investment on the most critical and expensive equipment, such as large chillers or essential walk-in freezers, where unplanned downtime would have the most severe financial impact.

Establish Performance Baselines: Once sensors are installed, run the equipment under normal conditions to collect baseline data. This historical benchmark is crucial for accurately identifying future deviations that signal a developing fault.

Set Intelligent Alert Thresholds: Work with your maintenance provider to set appropriate alarm thresholds. If they are too sensitive, you will be overwhelmed with false alerts; if they are too lenient, you risk missing critical warnings.

Train Technicians on Data Interpretation: Your team must be trained to understand what the data means. Empower them to move beyond turning wrenches and become data analysts who can interpret trends and make informed maintenance decisions. Platforms like Siemens MindSphere and IBM Watson IoT offer robust analytics tools to simplify this process.

4. Total Productive Maintenance (TPM) Implementation

Shifting maintenance from a departmental silo to a company-wide responsibility is a hallmark of truly advanced operations. Total Productive Maintenance (TPM) is a comprehensive strategy that involves all employees, from frontline operators to senior management, in proactive maintenance activities. This holistic approach aims to maximize equipment effectiveness by empowering operators with the skills to perform routine tasks, freeing up specialized technicians for more complex, value-added work.

TPM fundamentally changes the culture around equipment care, promoting a shared sense of ownership. It focuses on eliminating the "Six Big Losses" of production: breakdowns, setup and adjustment delays, idling and minor stoppages, reduced speed, process defects, and reduced yield. This makes TPM one of the most transformative preventive maintenance best practices because it integrates equipment health directly into daily operational culture, rather than treating it as a separate function.

Why Implement TPM?

The core benefit of TPM is achieving near-perfect production by eliminating downtime and defects. Toyota pioneered many TPM concepts within its Toyota Production System, achieving over 99% equipment availability across its global manufacturing plants. Similarly, consumer goods giant Procter & Gamble used TPM to improve Overall Equipment Effectiveness (OEE) by 20% and significantly reduce manufacturing costs.

For a facility manager, this means the team operating the commercial kitchen refrigeration units is also responsible for daily cleaning, basic checks, and logging performance anomalies. This "autonomous maintenance" by operators catches small issues before they escalate, allowing dedicated HVAC technicians to focus on strategic predictive tasks instead of constant reactive fixes. You can find out more by exploring this comprehensive guide to commercial equipment services, which details the collaborative efforts needed for peak performance. The result is a highly efficient, self-correcting system that drives continuous improvement.

Actionable Implementation Tips

To successfully embed TPM principles into your facility's operations, follow these structured steps:

Start with a Pilot Area: Select one critical system, such as a walk-in freezer or a specific HVAC unit, to launch your TPM initiative. This allows you to refine the process and demonstrate tangible successes to build buy-in.

Provide Extensive Training: Train operators on routine maintenance tasks like cleaning, lubrication, and basic inspections. At the same time, upskill maintenance staff in advanced diagnostics and proactive maintenance techniques.

Establish Clear Roles: Clearly define maintenance responsibilities. Operators own the day-to-day health of their equipment, while the maintenance team owns planned major overhauls, complex repairs, and training.

Use Visual Management Tools: Implement 5S workplace organization (Sort, Set in Order, Shine, Standardize, Sustain) to keep work areas clean and orderly. Use visual aids like checklists and performance charts to make equipment status easily understandable at a glance.

Measure and Communicate OEE: Track Overall Equipment Effectiveness (OEE) as your primary metric. Regularly share progress with all teams to keep everyone engaged and celebrate small wins to maintain momentum.

5. Adopting a Reliability-Centered Maintenance (RCM) Methodology

While scheduled maintenance is effective, Reliability-Centered Maintenance (RCM) takes a more strategic, surgical approach. RCM is a corporate-level methodology used to determine the most effective maintenance strategy for a physical asset in its specific operating context. It moves beyond generic manufacturer schedules to ask a fundamental question: "What is the consequence of failure?" This systematic process analyzes potential failure modes, their effects, and their consequences to prioritize maintenance tasks that preserve essential system functions.

For managers of facilities with mission-critical HVAC and refrigeration, such as a data center or a pharmaceutical cleanroom, RCM is one of the most advanced preventive maintenance best practices available. It ensures that maintenance resources are focused on preventing failures with the most significant safety, environmental, or operational consequences. Instead of changing a filter every month simply because it's on a calendar, RCM might determine that a pressure differential sensor is a more cost-effective way to signal the need for a change, reserving hands-on labor for more critical component inspections.

Why Adopt an RCM Approach?

Adopting an RCM methodology is about optimizing resources to maximize reliability and safety. The U.S. Navy famously pioneered RCM for its aircraft, resulting in massive cost savings and improved flight readiness. Similarly, the nuclear power industry relies heavily on RCM to manage safety-critical components where failure is not an option. This approach forces a deep understanding of how equipment operates and fails, leading to highly targeted and efficient maintenance plans.

The primary benefit is a maintenance program perfectly tailored to your operational needs and risk tolerance. It eliminates unnecessary maintenance tasks that add cost but provide little value, while simultaneously increasing focus on activities that prevent catastrophic failures. For a large cold storage facility, an RCM analysis might identify a specific compressor failure mode that could lead to millions in product loss, justifying the implementation of advanced predictive monitoring for that component alone, while reducing routine checks on less critical assets like circulation fans.

Actionable Implementation Tips

To effectively integrate RCM principles into your maintenance strategy, consider these practical steps:

Start with Critical Systems: Begin the RCM analysis process with your most critical assets. Focus on HVAC or refrigeration systems where failure would cause the most significant operational, financial, or safety impact.

Form a Cross-Functional Team: Involve experienced operators, maintenance technicians, and engineers in the analysis. Their collective, hands-on knowledge of how equipment actually fails is essential for an accurate assessment.

Follow a Standardized Framework: Use a recognized RCM methodology, such as the SAE JA1011 standard, to guide your process. This ensures a structured and comprehensive analysis covering all seven key RCM questions.

Document Everything: Meticulously document all analysis decisions, the rationale behind them, and the resulting maintenance tasks. This documentation becomes a living blueprint for your maintenance strategy and is crucial for training and future reviews.

6. Key Performance Indicators (KPI) and Metrics Management

What gets measured gets managed. This principle is the cornerstone of effective preventive maintenance, where intuition is replaced by data-driven decision-making. Key Performance Indicators (KPIs) and metrics management involve systematically tracking specific data points to evaluate the effectiveness of your maintenance program, identify areas for improvement, and clearly demonstrate its value to business operations. It’s the process of translating maintenance activities into the language of business: efficiency, cost, and reliability.

For managers of commercial facilities, tracking KPIs for HVAC and refrigeration systems provides objective proof of performance. Instead of simply stating that a maintenance plan is working, you can present concrete data showing reduced downtime, lower energy consumption, or fewer emergency repair calls. This approach is fundamental to preventive maintenance best practices because it creates a feedback loop for continuous improvement, ensuring your strategy adapts and evolves based on real-world results rather than assumptions.

Why Implement KPIs and Metrics Management?

Implementing a KPI framework is about achieving operational clarity and accountability. For instance, Chevron tracks maintenance performance indicators across its refineries to standardize safety protocols and optimize asset availability, linking maintenance directly to production goals. Similarly, Ford Motor Company utilizes a comprehensive KPI dashboard to measure maintenance effectiveness, which has been crucial in minimizing production line interruptions and controlling operational costs.

The core benefit is transforming maintenance from a perceived cost center into a proven value driver. By tracking metrics like Mean Time Between Failures (MTBF) for a critical rooftop AC unit, you can justify the cost of proactive component replacements before a catastrophic failure disrupts business. This data-driven approach allows for strategic resource allocation, helping you focus your budget and team's efforts where they will have the most significant impact. To gain a deeper understanding of how these metrics apply to specific systems, you can learn more about commercial HVAC and refrigeration maintenance and the data points that matter most.

Actionable Implementation Tips

To successfully integrate a KPI-driven approach into your maintenance operations, follow these practical steps:

Select 5-7 Key Metrics: Avoid "analysis paralysis" by focusing on a handful of metrics that align with your primary business objectives, such as Overall Equipment Effectiveness (OEE), Planned Maintenance Percentage (PMP), and maintenance cost per asset.

Automate Data Collection: Where possible, use your CMMS or Building Management System (BMS) to automate data collection. This reduces human error, ensures consistency, and provides real-time insights without adding to your team's workload.

Establish Realistic Targets: Use industry benchmarks from organizations like the Society for Maintenance & Reliability Professionals (SMRP) to set initial goals. Then, adjust these targets based on your unique operational context and historical performance.

Use Visual Dashboards: Display your KPIs on a visual dashboard that is easily accessible to the entire team. This transparency promotes accountability and allows for quick identification of performance trends, both positive and negative.

7. Maintenance Planning and Scheduling Optimization

Simply having a maintenance plan is not enough; optimizing its execution is where true efficiency is unlocked. Maintenance Planning and Scheduling Optimization is the systematic process of preparing, coordinating, and timing maintenance work to maximize resource use and minimize operational disruptions. It transforms a maintenance to-do list into a highly efficient, integrated workflow that ensures the right technician has the right parts and tools at the right asset at the right time.

For managers of commercial facilities, this practice moves maintenance from a source of unpredictable downtime to a smoothly running, value-adding function. It involves detailed job planning, precise resource allocation, and close coordination with production or operational schedules. This methodical approach is one of the most critical preventive maintenance best practices because it directly tackles wasted time, a major drain on resources. By ensuring every task is planned and scheduled, you eliminate the all-too-common scenario of technicians arriving unprepared or during a critical operational period.

Why Optimize Planning and Scheduling?

Optimizing your maintenance schedule is about gaining operational leverage and maximizing "wrench time," the portion of a technician's day spent performing hands-on work. For example, ExxonMobil achieved over 90% schedule compliance by implementing world-class planning, drastically reducing idle time and reactive work. Similarly, large pulp and paper companies use advanced scheduling to perfectly align critical maintenance with planned production outages, preventing millions in lost revenue.

The core benefit is maximizing asset availability while minimizing maintenance costs. Instead of pulling a critical chiller offline for a filter change during peak business hours, an optimized schedule would place that task during a low-occupancy period, planned weeks in advance. This proactive coordination, as advocated by experts like Doc Palmer and Don Nyman, ensures maintenance supports business goals rather than hindering them. This strategic approach extends equipment life, improves safety, and boosts team morale by replacing chaotic fire-fighting with predictable, well-organized work.

Actionable Implementation Tips

To elevate your maintenance from a simple checklist to a strategic operation, consider these practical steps:

Establish a Dedicated Planner Role: Assign the responsibility of planning and scheduling to a dedicated individual or team. This person should not be a supervisor but a specialist focused on preparing detailed work packages, estimating job times, and coordinating resources.

Coordinate with Operations: Hold weekly scheduling meetings with key stakeholders from operations or production. This collaboration is essential for aligning maintenance windows with business needs and preventing conflicts.

Use Data to Refine Estimates: Leverage historical data from your CMMS to improve time and resource estimates for recurring jobs. Accurate estimates are the foundation of a reliable schedule.

Maintain a Healthy Work Order Backlog: Aim to maintain a backlog of 2-4 weeks of planned, ready-to-execute work. This provides the flexibility needed to build efficient weekly schedules and adapt to changing priorities. A well-structured plan can be built using a comprehensive checklist; explore our preventive maintenance checklist template for guidance.

Preventive Maintenance Strategies Comparison

Item | Implementation Complexity | Resource Requirements | Expected Outcomes | Ideal Use Cases | Key Advantages |

|---|---|---|---|---|---|

Implementing Computerized Maintenance Management Systems (CMMS) | High initial cost, requires training and customization | Software licenses, IT infrastructure, trained staff | 10-20% downtime reduction, 300-500% ROI in 2-3 years | Large organizations needing centralized maintenance management | Automates work orders, improves planning, strong analytics integration |

Risk-Based Maintenance (RBM) Strategy | Complex risk assessments needing specialized expertise | Skilled analysts, risk assessment tools | 15-30% cost reduction, improved safety focus | Facilities with critical and high-risk assets | Prioritizes maintenance by risk, optimizes resource allocation |

Condition-Based Monitoring and Predictive Analytics | High initial investment, complex system integration | Sensors, IoT devices, data analysts | Up to 70% downtime reduction, 25-30% cost savings | Equipment needing continuous health monitoring | Early failure detection, just-in-time maintenance, extends equipment life |

Total Productive Maintenance (TPM) Implementation | Long-term cultural change, extensive training required | Training programs, management commitment | 15-25% OEE increase, 50-80% fewer breakdowns | Organizations focusing on operator involvement | Increases equipment effectiveness, builds maintenance culture |

Reliability-Centered Maintenance (RCM) Methodology | Time-intensive analysis, requires expert analysts | Skilled engineers, analysis frameworks | Reduced unnecessary tasks, improved reliability | Safety-critical and complex systems | Systematic failure analysis, optimizes maintenance tasks |

KPI and Metrics Management | Moderate complexity, requires data systems | Data collection tools, analytics software | Data-driven decision making, performance visibility | Organizations seeking to monitor and improve maintenance | Objective measurement, identifies trends and improvement areas |

Maintenance Planning and Scheduling Optimization | Requires dedicated planners, cross-department coordination | Skilled planners, scheduling software | 25-60% productivity increase, reduced downtime | Operations needing efficient maintenance coordination | Improves resource use, reduces emergency work, enhances safety |

Partnering for Peak Performance and Peace of Mind

Navigating the landscape of modern facility management reveals a clear truth: reactive maintenance is no longer a viable strategy. The journey from a costly, failure-driven approach to a proactive, predictive model is paved with the advanced preventive maintenance best practices we've explored. Moving beyond simple calendar-based checkups to embrace methodologies like Reliability-Centered Maintenance (RCM) and Total Productive Maintenance (TPM) represents a fundamental shift in operational philosophy.

This evolution is not just about scheduling tasks; it's about building a resilient, intelligent maintenance ecosystem. By integrating a Computerized Maintenance Management System (CMMS), you create a central nervous system for your operations, transforming raw data into actionable intelligence. Layering on strategies like Risk-Based Maintenance (RBM) allows you to allocate resources with surgical precision, focusing your efforts where they will have the most significant impact on preventing catastrophic failures and minimizing operational disruptions.

From Data to Decisions: The Core Takeaway

The most critical takeaway is the power of data-driven decision-making. The days of relying on intuition or generic schedules are over. Implementing Condition-Based Monitoring and leveraging Key Performance Indicators (KPIs) are no longer optional luxuries but essential tools for any competitive business. These practices enable you to:

Anticipate Failures: Move from fixing broken equipment to predicting and preventing issues before they occur.

Optimize Resources: Ensure your technicians, time, and budget are invested in the most critical maintenance activities.

Enhance System Lifespan: Maximize the return on your significant HVAC and refrigeration investments by improving their longevity and efficiency.

Ultimately, mastering these advanced preventive maintenance best practices is about gaining control. It’s about transforming your maintenance department from a cost center into a strategic asset that directly contributes to your bottom line through enhanced reliability, improved energy efficiency, and operational stability.

Your Actionable Next Steps

Implementing such a comprehensive program can seem daunting, but it begins with a single, strategic step. The initial priority is to assess your current state. Evaluate your existing maintenance procedures, documentation practices, and technological capabilities. Identify the most frequent and costly points of failure within your HVAC and refrigeration systems. This internal audit provides the baseline necessary to select the right methodologies-be it RCM for critical assets or TPM to foster a culture of collective ownership.

From there, you can develop a phased implementation plan. Start small, perhaps by piloting a CMMS for a single critical system or introducing specific KPIs to track performance. This iterative approach allows your team to adapt and build expertise without overwhelming your operations. The goal is consistent, incremental progress toward a fully optimized maintenance strategy that protects your assets and secures your peace of mind. For businesses in West Florida, from Sarasota to St. Petersburg, this journey doesn't have to be a solo endeavor. Partnering with a specialist can accelerate your progress and ensure these frameworks are applied effectively, bridging the gap between theory and tangible results.

Ready to transform your maintenance strategy from a reactive burden into a competitive advantage? The certified experts at Putnam Mechanical LLC specialize in designing and executing customized preventive maintenance programs that incorporate these advanced best practices for businesses throughout West Florida. Visit Putnam Mechanical LLC today to schedule a consultation and discover how our revolutionary customer service and technical expertise can ensure your systems operate at peak performance.

_edited%20copy.png)