7 Facility Management Best Practices for 2025 Success

- Aug 26, 2025

- 14 min read

In today's competitive landscape, simply keeping the lights on isn't enough. Proactive, strategic facility management is the engine that drives operational excellence, ensuring safety, efficiency, and significant cost savings. Many businesses struggle with reactive maintenance, which leads to unexpected breakdowns, soaring energy bills, and compliance headaches, especially with critical systems like commercial HVAC and refrigeration. This cycle of costly repairs and downtime can directly impact your bottom line and customer satisfaction.

This guide moves beyond the basics, offering seven actionable facility management best practices designed for today’s demanding environments. We will explore how to transform your operations from a necessary cost center into a strategic asset. You will learn how to leverage everything from predictive maintenance programs to integrated smart building technology.

Adopting these advanced practices will not only streamline your daily operations but also future-proof your facility against rising costs and evolving regulations. The goal is to create a more resilient, sustainable, and productive environment. By implementing these strategies, you can gain a distinct competitive advantage, ensuring your physical assets actively contribute to your organization's success. Let's dive into the specific methods that will get you there.

1. Preventive Maintenance Programs

A proactive approach is the cornerstone of effective facility management best practices, and nothing embodies this principle more than a structured preventive maintenance (PM) program. Rather than reacting to equipment breakdowns as they happen, this strategy involves scheduled inspections, servicing, and component replacements to address potential issues before they escalate into costly failures.

This systematic method moves maintenance from a reactive, emergency-based expense to a predictable, budgeted operational cost. By regularly servicing critical systems like HVAC and refrigeration units, organizations can significantly extend asset lifecycles, ensure consistent performance, and maintain a safe, comfortable environment for employees and customers.

Why It's a Top Practice

Implementing a PM program is a fundamental shift that directly impacts your bottom line and operational stability. It minimizes unexpected downtime, which is especially critical in industries like hospitality, manufacturing, or retail where equipment failure can halt business entirely. For example, General Motors leverages PM to achieve an astounding 99.5% equipment availability in its plants, a benchmark for operational excellence. Similarly, Marriott Hotels applies consistent PM schedules across its 7,000+ properties to ensure guest comfort and avoid expensive emergency repairs.

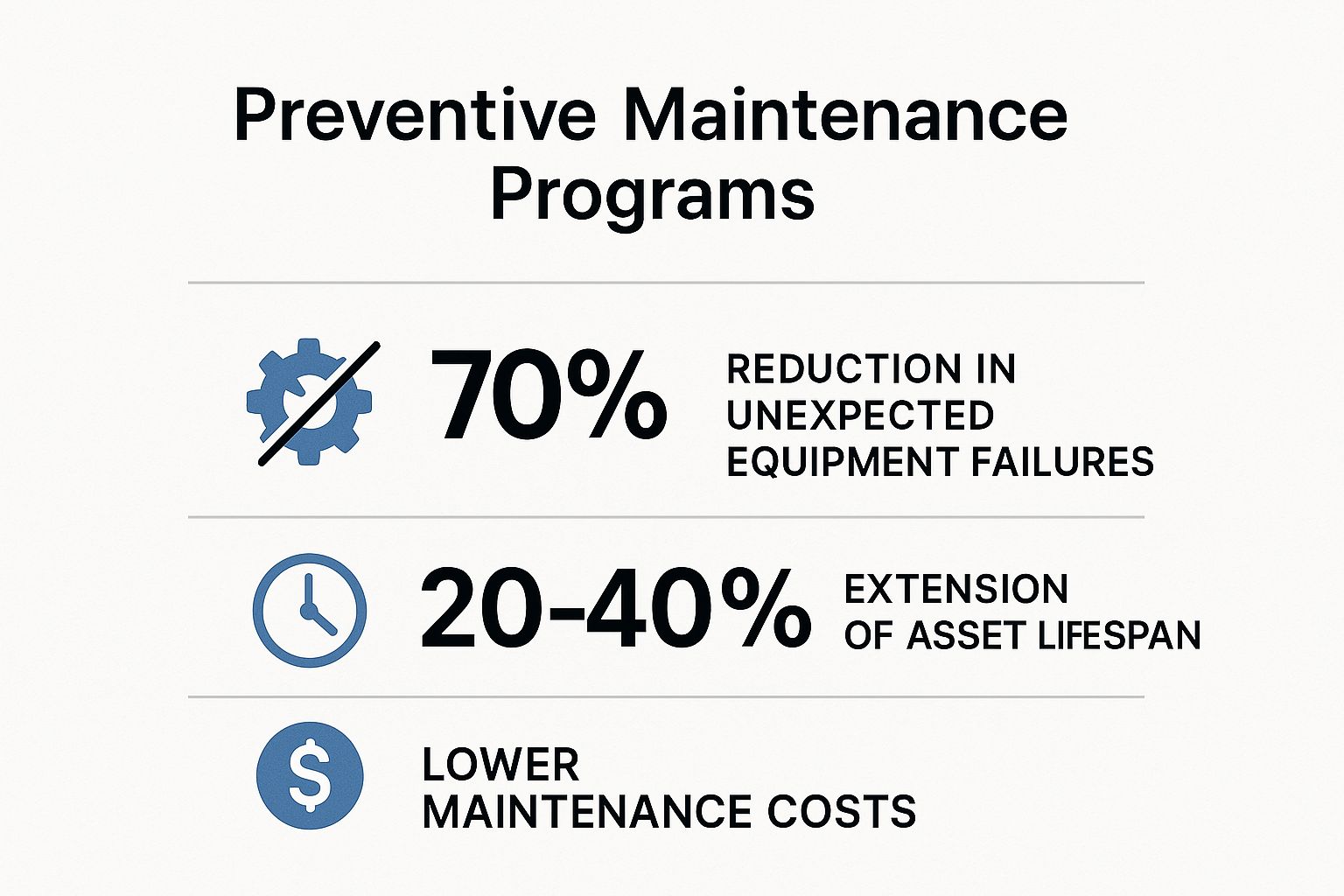

The following infographic highlights the compelling financial and operational benefits of adopting a preventive maintenance strategy.

These metrics clearly show that the upfront investment in planned maintenance pays significant dividends by reducing costly failures and maximizing the value of your assets.

How to Implement It

Getting started with a PM program doesn't have to be overwhelming. Follow these actionable steps:

Prioritize Critical Assets: Begin by identifying the equipment most crucial to your operations. For a restaurant, this would be refrigeration units and kitchen exhaust systems; for an office building, it’s the primary HVAC system.

Establish a Baseline Schedule: Use manufacturer recommendations as your starting point for maintenance frequency and tasks. This ensures you comply with warranty requirements.

Leverage Technology: Equip your technicians with mobile maintenance management apps to streamline work orders, access equipment history, and document completed tasks in real-time.

Track Performance: Monitor key performance indicators (KPIs) like Mean Time Between Failures (MTBF) to measure the effectiveness of your program and identify areas for improvement.

For a deeper dive into creating a robust schedule for your HVAC systems, you can learn more about 7 preventive maintenance best practices for HVAC on pmechanicalfl.com.

2. Space Utilization Optimization

One of the most impactful facility management best practices for the modern era is the strategic optimization of physical space. This involves more than just fitting people into an office; it's about analyzing how every square foot is used, identifying underutilized areas, and reconfiguring layouts to boost efficiency, cut operational costs, and enhance the employee experience.

As work patterns evolve with hybrid and remote models, a static, one-size-fits-all office is no longer effective. Optimizing space means creating a dynamic environment that aligns with how teams actually work today, reducing expenses on heating, cooling, and maintaining empty desks or conference rooms.

Why It's a Top Practice

Effective space utilization directly translates to significant cost savings and improved productivity. By understanding real-world usage patterns, organizations can consolidate their footprint, sublease excess space, or reallocate areas for more valuable purposes like collaboration zones or employee wellness rooms. For instance, Unilever uses occupancy sensors across its global offices to achieve an impressive 85% utilization rate, ensuring real estate costs are closely tied to actual need. Similarly, Microsoft strategically reduced its physical office space by 50% while maintaining productivity by embracing a hybrid work model supported by optimized, bookable workspaces.

This data-driven approach transforms real estate from a fixed overhead into a flexible, strategic asset that supports organizational goals and employee well-being.

How to Implement It

Optimizing your facility's layout can be achieved through a clear, step-by-step process. Here’s how to get started:

Conduct Space Utilization Audits: Use a combination of technology like IoT occupancy sensors and direct observation to gather accurate data on how different areas are used throughout the day and week.

Embrace Flexible Work Models: Implement strategies like "hot-desking" (unassigned seating) or Activity-Based Working (ABW), where employees choose from various work settings tailored to specific tasks.

Deploy Booking Technology: Use mobile apps and integrated software to allow employees to easily reserve desks, meeting rooms, and other resources, which also provides valuable utilization data.

Involve Your Team: Gather employee feedback through surveys and workshops to understand their needs and preferences. Involving them in the planning process ensures the new layout is both functional and well-received.

For a deeper look at how technology is reshaping workplace design, you can explore how IoT is revolutionizing smart buildings on the Propmodo blog.

3. Energy Management and Sustainability

Modern facility management best practices extend beyond just maintaining equipment; they encompass a strategic approach to reducing environmental impact and controlling operational costs. An integrated energy management and sustainability program involves monitoring, controlling, and optimizing energy consumption across all facility systems, particularly high-usage assets like HVAC and refrigeration.

This approach combines smart building technologies, green building certifications, and sustainable operational procedures to achieve significant cost savings and meet corporate responsibility goals. By systematically reducing a facility's carbon footprint, organizations can enhance their brand reputation while simultaneously improving their bottom line.

Why It's a Top Practice

A focus on sustainability is no longer optional; it's a competitive advantage that delivers tangible returns. For example, the famous Empire State Building retrofit reduced its energy use by 38%, saving $4.4 million annually. Similarly, Google's data centers use AI-powered cooling optimization to consume 50% less energy than the industry average, showcasing how technology-driven sustainability can lead to massive operational efficiencies.

These initiatives prove that strategic energy management directly translates to lower utility bills, increased asset value, and compliance with evolving environmental regulations. Popularized by frameworks like LEED certification and building automation leaders like Johnson Controls, this practice is a cornerstone of a resilient and forward-thinking facility strategy.

How to Implement It

Integrating sustainability into your facility operations can be a phased, manageable process. Here are key steps to get started:

Conduct an Energy Audit: The first step is to identify your biggest energy consumption sources and areas of waste. This data-driven baseline is crucial for prioritizing your efforts.

Implement Smart Controls: Install occupancy sensors, smart thermostats, and automated lighting controls to ensure energy is only used when and where it's needed.

Upgrade to Efficient Equipment: When replacing or upgrading systems like HVAC units or commercial refrigerators, prioritize models with high Energy Star ratings to guarantee long-term efficiency.

Establish Real-Time Monitoring: Use energy management dashboards to track consumption in real-time. This allows facility managers to spot anomalies and address issues before they lead to high utility bills.

To understand the foundational step of this process, discover more about how an HVAC energy audit can lower your operating costs on pmechanicalfl.com.

4. Integrated Workplace Management Systems (IWMS)

Moving beyond siloed spreadsheets and disconnected software, a core facility management best practice is centralizing operations through an Integrated Workplace Management System (IWMS). This comprehensive software platform consolidates key functions like maintenance management, space planning, real estate portfolio oversight, and sustainability tracking into a single, unified database.

By integrating disparate data streams, an IWMS provides a holistic view of your entire facility ecosystem. This allows for more strategic, data-driven decision-making, transforming facility management from a collection of reactive tasks into a cohesive operational strategy that aligns directly with broader business objectives.

Why It's a Top Practice

Adopting an IWMS is a game-changer for organizations managing large or complex portfolios, enabling them to optimize resources at a macro level. It eliminates data redundancy, improves communication between departments, and provides powerful analytics for forecasting and budgeting. For instance, the General Services Administration (GSA) uses an IWMS to effectively manage its massive portfolio of 370 million square feet of federal real estate. Similarly, global pharmaceutical leader Pfizer leverages Archibus IWMS to optimize space utilization across its R&D facilities, ensuring expensive lab space is used efficiently.

This centralized intelligence helps managers identify trends, reduce operational costs, and improve the overall performance and sustainability of their buildings, making it an indispensable tool for modern facility management.

How to Implement It

Successfully deploying an IWMS requires careful planning and a phased approach. Follow these actionable steps for a smooth transition:

Define Clear Requirements: Before evaluating vendors like IBM TRIRIGA or Planon, identify your specific operational challenges and define clear success metrics. What problems are you trying to solve?

Prioritize Core Modules: Start with the most critical functions for your business, such as maintenance and space management. You can expand to other modules like capital project management or sustainability tracking later.

Plan for Data Migration: A successful implementation hinges on clean data. Allocate significant time and resources to cleanse, format, and migrate your existing asset, maintenance, and lease data into the new system.

Invest in Comprehensive Training: Ensure all user levels, from technicians to executives, receive role-specific training. This drives user adoption and maximizes the return on your software investment.

For those exploring software solutions, G2 offers a detailed comparison of top IWMS software options to help you find the right fit for your organization.

5. Vendor Management and Strategic Partnerships

No facility operates in a vacuum, making the systematic management of external service providers a critical component of modern facility management best practices. This approach involves selecting, managing, and optimizing relationships with vendors to ensure high-quality service, cost-effectiveness, and risk mitigation. It moves beyond a purely transactional dynamic to build collaborative partnerships that align vendor capabilities with your organization's strategic goals.

By establishing clear service level agreements (SLAs), performance metrics, and open lines of communication, you transform suppliers from mere contractors into valuable extensions of your team. This strategic alignment ensures that every external partner, from HVAC technicians to custodial staff, contributes directly to your operational efficiency and long-term success.

Why It's a Top Practice

Effective vendor management is about maximizing value, not just minimizing cost. Strategic partnerships give you access to specialized expertise and resources you may not have in-house, ensuring tasks are performed correctly and efficiently. For example, Apple partners with JLL for comprehensive global facility management, leveraging JLL's expertise to maintain its high standards across all properties. Similarly, Amazon Web Services relies on strategic partners for its complex data center operations, ensuring reliability and uptime.

This approach mitigates risk by ensuring vendors are properly vetted, insured, and compliant with safety regulations. It also fosters innovation, as trusted partners are more likely to recommend new technologies or process improvements that can benefit your facility.

How to Implement It

Building a robust vendor management framework requires a structured and consistent process. Follow these actionable steps:

Develop Comprehensive Evaluation Criteria: Look beyond the lowest bid. Evaluate potential vendors on their experience, reliability, safety record, and cultural fit with your organization.

Establish Clear Performance Metrics: Define your expectations in a formal SLA. Include key performance indicators (KPIs) like response times, work quality standards, and communication protocols.

Foster Collaborative Relationships: Schedule regular performance reviews to discuss successes and challenges. Treat vendors as partners by sharing relevant business goals and listening to their expert advice.

Use Technology for Tracking: Implement a vendor management system or use your CMMS to track performance, manage contracts, and streamline communication, creating a single source of truth for all vendor interactions.

When selecting partners, especially for critical systems like HVAC, it's essential to find the right fit for your specific needs. To understand this better, you can explore the nuances of choosing an HVAC company on pmechanicalfl.com.

6. Risk Management and Business Continuity Planning

Beyond routine maintenance, one of the most crucial facility management best practices involves preparing for the unexpected. A comprehensive risk management and business continuity plan provides a framework for identifying, assessing, and mitigating facility-related risks to ensure operations continue during a disruption. This strategy covers everything from emergency preparedness and disaster recovery to security management, protecting people, assets, and business functions.

This forward-thinking approach prepares your organization to handle various threats, including natural disasters, utility failures, or security breaches. By having clear protocols in place, you can minimize damage, protect stakeholders, and restore normal operations far more quickly than if you were reacting without a plan.

Why It's a Top Practice

Effective risk management is not just about disaster recovery; it's about building organizational resilience. It safeguards your reputation, ensures employee safety, and protects your financial stability. For instance, financial institutions like JPMorgan Chase maintain fully redundant data centers to guarantee uninterrupted service, a non-negotiable for their industry. Similarly, large-scale venues like Disney's theme parks conduct regular, rigorous drills for countless scenarios, ensuring guest safety and operational continuity remain paramount.

For commercial properties, even a single critical system failure, like an HVAC outage during a heatwave, can halt business. A robust plan anticipates such events, outlining immediate actions to mitigate impact and protect assets, a principle that underscores the importance of proactive system care.

How to Implement It

Building a resilient facility requires a structured and repeatable process. Follow these actionable steps to get started:

Conduct a Risk Assessment: Identify potential threats specific to your facility and location, such as hurricanes, power grid failures, or equipment malfunctions. Analyze the potential impact of each risk on your operations.

Develop Emergency Protocols: Create clear, step-by-step procedures for various scenarios. This includes evacuation plans, communication trees, and instructions for shutting down critical systems safely.

Test and Refine Your Plan: Regularly conduct drills and tabletop exercises to test your emergency procedures. Use the findings to identify weaknesses and update your plan accordingly.

Ensure System Redundancy: Test backup systems, such as generators and secondary HVAC units, on a routine schedule to confirm they are ready to perform when needed.

Developing a business continuity plan often highlights the immense operational risk tied to core systems. To understand more about mitigating these risks through proactive care, you can learn more about why property managers should prioritize routine HVAC maintenance on pmechanicalfl.com.

7. Technology Integration and Smart Building Solutions

Modern facility management best practices increasingly rely on harnessing the power of technology to create intelligent, responsive, and efficient building environments. This involves the strategic integration of Internet of Things (IoT) sensors, building automation systems (BAS), and data analytics to optimize performance. By connecting disparate systems like HVAC, lighting, and security, facilities can operate cohesively, adjusting to real-time conditions automatically.

This intelligent approach transforms a building from a static structure into a dynamic ecosystem. It allows for continuous monitoring and automated adjustments that enhance occupant comfort, reduce energy consumption, and provide facility managers with a wealth of actionable data. The goal is to move beyond scheduled operations and toward a predictive, data-driven management model.

Why It's a Top Practice

Integrating smart technology is no longer a futuristic concept; it's a competitive advantage that delivers tangible returns on investment. Smart buildings can significantly lower operational costs by optimizing energy usage based on occupancy and environmental conditions. For instance, The Edge in Amsterdam, often cited as the world's smartest building, uses 28,000 sensors to manage everything from temperature to desk availability, resulting in extreme energy efficiency.

Similarly, Salesforce Tower in San Francisco employs smart environmental controls and elevator systems to enhance the employee experience and minimize its carbon footprint. These examples prove that a well-integrated technology stack can drive both sustainability and operational excellence, making it a crucial practice for forward-thinking facility managers.

How to Implement It

Adopting smart building technology can be approached in manageable phases. Follow these actionable steps to ensure a successful integration:

Start with Pilot Projects: Begin with a focused initiative, such as installing smart thermostats in a specific zone or IoT sensors on a critical HVAC unit, to test the technology and demonstrate its value before a full-scale deployment.

Prioritize Interoperability: Select systems and platforms that use open standards. This ensures that technologies from different vendors can communicate with each other, preventing you from being locked into a single ecosystem.

Ensure Robust Cybersecurity: As you connect more devices to your network, cybersecurity becomes paramount. Implement strong security protocols, conduct regular updates, and train staff to recognize potential threats.

Train Your Team: Equip your staff with the knowledge to manage and leverage the new technologies. Establish clear procedures for monitoring data, responding to alerts, and utilizing the system's analytical capabilities.

Smart technology often works best when paired with solid maintenance fundamentals. To understand how this tech can help prevent failures, you can learn more about how regular maintenance prevents costly equipment breakdowns on pmechanicalfl.com.

Facility Management Best Practices Comparison

Item | Implementation Complexity | Resource Requirements | Expected Outcomes | Ideal Use Cases | Key Advantages |

|---|---|---|---|---|---|

Preventive Maintenance Programs | Moderate to high; requires planning, training | Dedicated maintenance staff, CMMS | Reduced equipment failures, extended asset life | Industrial, manufacturing, large facilities | Lowers maintenance costs, improves safety |

Space Utilization Optimization | Moderate; involves sensors and data analysis | Occupancy sensors, analytics tools | Reduced real estate costs, improved productivity | Offices with hybrid/flexible work environments | Enhances space efficiency, supports flexible work |

Energy Management and Sustainability | High; involves integration of smart systems | Capital-intensive tech, technical experts | Lower energy costs, improved sustainability | Commercial buildings, data centers, campuses | Reduces energy costs, qualifies for certifications |

Integrated Workplace Management Systems (IWMS) | High; complex software implementation | IT support, user training, software licenses | Centralized data, cost reduction, compliance | Large multi-site organizations | Eliminates silos, comprehensive analytics |

Vendor Management and Strategic Partnerships | Low to moderate; process-driven | Vendor oversight, performance tracking | Cost control, quality service, risk mitigation | Organizations relying on multiple vendors | Access to expertise, scalability |

Risk Management and Business Continuity Planning | Moderate to high; extensive coordination | Backup systems, emergency planning staff | Minimized disruption, enhanced safety | Critical facilities, hospitals, financial centers | Protects assets and people, ensures compliance |

Technology Integration and Smart Building Solutions | High; requires tech deployment and integration | IoT devices, software, technical skills | Real-time monitoring, predictive maintenance | Smart buildings, high-tech offices, campuses | Automation, improved comfort, energy efficiency |

Build a Resilient Facility, Starting Today

Navigating the complexities of modern facility management requires more than just reacting to problems as they arise. It demands a strategic, forward-thinking approach. The best practices detailed in this article, from implementing a robust preventive maintenance program to integrating smart building technology, are not isolated tactics. They are interconnected pillars that support a resilient, efficient, and cost-effective operational framework.

By embracing these principles, you shift your facility's posture from reactive to proactive. You move beyond day-to-day firefighting and begin architecting a future where your buildings actively contribute to your organization's success. This is the core of effective facility management: transforming a physical space from a cost center into a strategic asset that enhances productivity, ensures safety, and supports long-term growth.

Key Takeaways for Immediate Impact

The journey toward operational excellence is a continuous one, but you can start making significant strides today. The most crucial takeaway is that small, consistent improvements compound over time. Focusing on a few high-impact areas first will build momentum for broader change.

Consider these central themes from our discussion:

Data is Your Ally: Whether optimizing space utilization or managing energy consumption, data-driven decisions consistently outperform guesswork. An Integrated Workplace Management System (IWMS) is the engine for this, centralizing information and providing actionable insights.

Prevention Outweighs Reaction: The upfront investment in a comprehensive preventive maintenance schedule for critical systems like HVAC and refrigeration delivers exponential returns. It minimizes costly emergency repairs, extends equipment lifespan, and prevents disruptive downtime.

Partnerships are Power: You cannot be an expert in everything. Cultivating strategic partnerships with specialized vendors, especially for complex technical systems, provides access to expertise, ensures compliance, and allows your team to focus on core responsibilities.

Your Actionable Path Forward

Implementing these facility management best practices might feel overwhelming, but progress is made one step at a time. Start by conducting a thorough audit of your current operations. Where are your biggest pain points? Are they frequent equipment failures, soaring utility bills, or inefficient use of space?

Use your findings to prioritize one or two key areas. For instance, if unexpected HVAC breakdowns are crippling your budget and operations, your first step is clear: formalize a preventive maintenance plan. If your team is buried in manual administrative work, exploring IWMS or other technology integrations should be your top priority. By adopting this methodical approach, you build a stronger, more resilient facility that is prepared for the challenges of tomorrow while performing optimally today.

Ready to master your facility's most critical systems? For specialized expertise in commercial HVAC and refrigeration, a proactive partnership is key. Let Putnam Mechanical LLC help you implement the facility management best practices that protect your assets, control costs, and eliminate downtime. Contact our team today to build your custom preventive maintenance plan.

_edited%20copy.png)