Restaurant Refrigeration Repair Near Me Done Right

- Sep 12, 2025

- 13 min read

When a kitchen freezer or walk-in cooler goes down, every single minute costs you money. That’s why searching for restaurant refrigeration repair near me the moment you spot a problem is so critical—it gets you fast, local service before a small leak turns into a full-blown inventory disaster.

Why Quick Repair Is Essential

A broken refrigerator is much more than a loose gasket or a warm drawer. In a busy restaurant, it's the heart of the operation, keeping thousands of dollars worth of ingredients safe and ready for service.

The second that cooling stops, fresh produce, dairy, and proteins can start to spoil in just a few hours. The result? Wasted stock and an immediate hit to your revenue.

The fallout from a breakdown happens fast:

Spoiled inventory that forces you to 86 menu items last-minute.

Serious health code risks that could lead to fines or even a temporary closure.

Unexpected emergency repair fees that blow your maintenance budget out of the water.

Skyrocketing energy bills as struggling compressors work overtime, drawing more and more power.

Beyond the direct costs, a refrigeration failure can quickly lead to customer frustration. A warm display case or a limited menu can tarnish your reputation overnight and make regulars think twice about coming back.

The Ripple Effect of a Failing System

When a compressor is forced to work too hard, it doesn't just struggle—it guzzles electricity. Things like dirty coils and aging parts put a massive strain on the entire system, forcing it to run constantly just to keep up.

In fact, neglecting regular maintenance and putting off repairs on commercial refrigeration systems has serious financial consequences. Studies have shown that improper upkeep can raise energy bills significantly as the units are forced to overwork. You can learn more about the true cost of neglecting refrigeration maintenance and see how the numbers add up.

Getting a local technician on-site quickly is the best way to minimize downtime, preserve food quality, and protect your brand's integrity.

"A single hour without proper cooling can easily cost a restaurant hundreds of dollars in spoiled goods and lost sales."

Protecting Your Operation

The best way to handle a refrigeration breakdown is to have a plan in place before it ever happens.

Identify a local service partner that offers 24/7 emergency response.

Schedule routine inspections and tune-ups before your busiest seasons.

Consider investing in a small inventory of common replacement parts to reduce wait times for technicians.

Taking these steps helps you avoid that panicked, late-night search for "restaurant refrigeration repair near me" and keeps your kitchen running like a well-oiled machine.

Regular maintenance also helps you ace your health inspections. Consistent, reliable temperatures are key to food safety, ensuring your logs are perfect and you’re fully prepared for any unexpected audits.

That’s why calling for restaurant refrigeration repair near me at the first sign of trouble is one of the smartest moves you can make to protect both your profit margins and your peace of mind.

Local technicians mean faster response times, which directly translates to less food spoilage and lower costs. Keep your cool by having a trusted expert on speed dial.

Identifying Common Refrigeration Warning Signs

Your commercial refrigeration units are always trying to tell you something about their health, but they don't exactly speak English. Learning to spot the subtle warning signs is like a chef knowing the difference between a simmer and a boil—it lets you step in before a small hiccup turns into a full-blown crisis. Ignoring these signals is a surefire way to end up with spoiled inventory and massive emergency repair bills.

Instead of waiting for a total meltdown, your team can be your first line of defense. When they recognize the early symptoms, they can give a technician valuable information. This makes the search for "restaurant refrigeration repair near me" a lot faster and the diagnosis far more accurate.

The Unsettling Puddle

Finding a pool of water on the floor around your walk-in cooler or reach-in freezer is a classic red flag. It might look like a simple spill, but it often points to a deeper mechanical issue that needs attention right away.

This puddle could be caused by a few different problems:

A Clogged Drain Line: Condensation has to go somewhere. When the drain line gets blocked with food scraps or ice, water has nowhere to go but out onto your floor.

A Damaged Door Seal: If the gasket around the door is cracked or torn, it’s letting warm, moist air seep in. Your cooling system has to work overtime to compensate, creating way too much condensation for the drain to handle.

Coolant Leaks: In more serious cases, that puddle might not be water at all. A chemical refrigerant leak is a major safety risk and a sign that your system is on the verge of failing.

The Slow Temperature Creep

One of the most dangerous warning signs is a gradual rise in your unit's internal temperature. It might only be a few degrees at first—barely noticeable on the thermostat—but this "temperature creep" is a clear sign your system is struggling.

This usually happens when a key component is on its way out, like a worn-out compressor, a faulty thermostat, or low refrigerant levels. The unit runs nonstop, guzzling electricity and putting a ton of strain on its motor just to hold a barely acceptable temperature. If you ignore this, you risk food spoilage long before the unit fails completely, which is a huge health code violation.

A refrigeration unit that can't hold its temperature is more than an inconvenience; it's a liability. Consistent temperature control is the cornerstone of food safety and regulatory compliance.

The Frost Takeover

A thin layer of frost can be normal, but if you suddenly see a massive buildup of ice on the evaporator coils or interior walls, you’ve got a big problem. This "frost takeover" acts like a thick winter coat, insulating the coils and preventing the system from actually cooling the air.

This is almost always a sign of a broken automatic defrost system. The defrost heater, timer, or thermostat has likely failed, so the unit can't run its regular melting cycle. This forces the compressor to fight against the ice, tanking its efficiency and leading to an inevitable breakdown.

For a deeper look into these issues, our guide on the signs your refrigeration system needs immediate attention offers more valuable insights. Catching these problems early is the key to avoiding costly downtime.

What a Professional Repair Service Looks Like

When your walk-in cooler suddenly gives out, the stress can feel like a tidal wave. But knowing what to expect from a professional repair service can turn a full-blown emergency into a clear, manageable process. Understanding each step helps you get transparent, efficient service right when you need it most.

It all starts with your first phone call. A good dispatcher will ask for the important details to make sure the right technician with the right tools shows up. Be ready to share the equipment type (like a walk-in freezer or prep table cooler), the brand, and exactly what’s going wrong.

The Diagnostic and Quoting Stage

Once the technician arrives, they put on their detective hat. They’ll run a full diagnostic assessment, which is way more than just a quick peek. Using specialized tools, they'll check refrigerant levels, test electrical connections, and inspect key components like compressors and fan motors to find the true source of the problem.

After the diagnosis, you’ll get a detailed quote. A transparent quote should break down all the costs, so there are no surprises later.

Parts: The cost for any replacement components, whether it's a simple thermostat or a brand-new compressor.

Labor: The estimated time the repair will take, billed at the company’s hourly rate.

Trip Fees: Some companies charge a flat fee for coming out to your location, though many solid services will waive this.

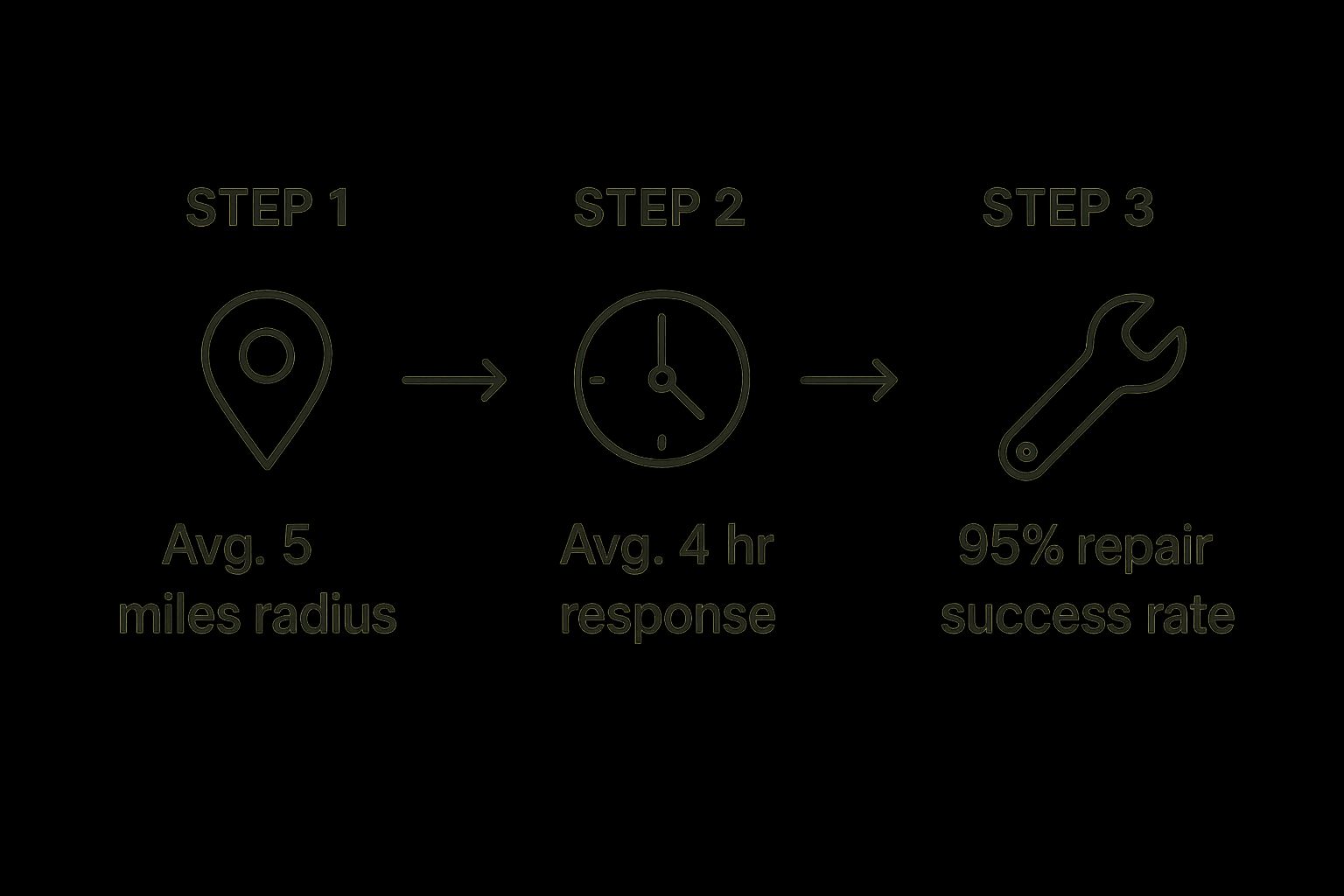

This infographic gives you a snapshot of a typical workflow for a local repair service, showing the kind of speed and success you should look for.

The numbers show that a quality local service should respond fast within a tight radius and have a high success rate on first-time repairs.

Final Repair and System Testing

After you give the green light on the quote, the technician gets to work. They’ll replace the bad parts, fix any leaks, or make the adjustments needed to get your equipment back online. This is where real expertise shines—a shoddy repair can lead to more problems or even bigger damage down the road.

A professional repair isn’t done just because a new part is in. The final, most important step is testing the whole system to make sure it’s running at the perfect temperature and peak efficiency.

The technician will run the unit, watch its cooling cycle, and confirm that it holds a stable, safe temperature. This final check is your guarantee that the problem is truly solved and your inventory is safe.

As the demand for reliable service grows, understanding this process helps you pick a true pro. The commercial refrigeration repair market is expected to hit $7 to $8 billion by 2025, driven by the needs of kitchens just like yours. To see how this process plays out in the real world, check out our guide on finding a trusted commercial refrigeration repair near me.

How to Choose the Right Local Repair Service

When your walk-in cooler dies in the middle of a dinner rush, the first company you find on Google can feel like a lifesaver. But let’s be honest—not all technicians are created equal. Choosing the right local service isn’t just about a quick fix. It’s about finding a reliable partner who can protect your inventory, guarantee food safety, and get you back up and running with minimal downtime.

Think of it like hiring a sous chef. You wouldn't hire the first person who walked through the door. You'd check their experience, see if they can handle the pressure, and make sure they have the right skills. The same logic applies here. A rushed decision can easily lead to repeat breakdowns, overpriced parts, and even more lost revenue down the line.

Key Questions to Ask Before You Hire

Before you make the call, take just a few minutes to vet any potential companies. How they answer these simple questions will tell you a lot about their professionalism and whether they’re up to the job.

Do you offer 24/7 emergency service? A refrigeration failure doesn’t care that it’s 9 p.m. on a Saturday. You need a company that will actually answer the phone and send a technician, whether it’s a holiday weekend or the middle of the night.

Are your technicians EPA 608 certified? This isn’t just a nice-to-have certification; it’s the law. EPA 608 certification means technicians are qualified to handle refrigerants safely and correctly, protecting your equipment and the environment.

What’s your average response time for local emergencies? Ask them for a realistic window. A trustworthy company will be straight with you, usually promising a response within a few hours for critical equipment failures.

How do you structure your pricing? Get the details on trip fees, hourly labor rates, and how they mark up parts. Transparent pricing from the start prevents that gut-punch feeling when the final invoice arrives.

Evaluating Online Presence and Reviews

In this day and age, a company's digital footprint says a lot about its reputation and customer service. A key part of this is [optimizing their Google Business Profile](https://www.shopmentor.io/blog/how-to-optimize-google-business-profile), which is often the first place you'll look for information.

A well-maintained online profile with recent, positive reviews is a sign of an active, reputable business that values its customers. Look for responses to both positive and negative feedback, as this shows accountability.

Check for reviews from other local restaurant owners. Their experiences can give you invaluable insight into a company's reliability and expertise in a commercial kitchen environment. While this is similar to choosing other major systems for your business, the urgency of a refrigeration failure adds another layer. You can find related principles in our guide on [how to choose the right HVAC system for your business](https://www.pmechanicalfl.com/post/how-to-choose-the-right-hvac-system-for-your-business).

To make things easier, use a simple checklist to keep track of the companies you're considering.

Comparing Local Refrigeration Repair Services

Use this checklist to evaluate and compare potential repair companies to find the best fit for your restaurant's needs.

Evaluation Criteria | Company A | Company B | Company C |

|---|---|---|---|

Offers 24/7 Emergency Service? | |||

EPA 608 Certified Technicians? | |||

Average Emergency Response Time | |||

Transparent Pricing Structure? | |||

Positive Local Online Reviews? | |||

Experience with Restaurants? | |||

Licensed and Insured? | |||

Provides Warranty on Parts/Labor? |

Ultimately, your goal is to find a provider who acts less like a one-time contractor and more like a true partner. By asking the right questions and doing a little homework, you can ensure the technician who shows up is qualified, trustworthy, and ready to get your kitchen back to business.

Shift from Reactive Repairs to Proactive Care

Waiting for a total breakdown before you start searching for "restaurant refrigeration repair near me" is like waiting for your car’s engine to seize before you change the oil. It’s a stressful, expensive, and completely avoidable spot to be in. The smartest move is to shift away from reactive repairs and embrace proactive care, where the goal isn't just to fix problems but to stop them from happening in the first place.

Think of a proactive maintenance plan as a regular tune-up for your most valuable kitchen assets. A technician doesn't just show up when something’s on the fritz; they visit on a schedule to perform vital health checks. This simple change in mindset can save you thousands in emergency costs and spoiled inventory.

The Anatomy of a Strong Maintenance Plan

A real maintenance plan is way more than just a quick look-over. It's a detailed service designed to catch the small stuff before it snowballs into a full-blown system failure. While plans can vary, any quality service should always cover a few core tasks.

Key maintenance activities should include:

Thorough Coil Cleaning: A technician will professionally clean the condenser and evaporator coils. This is crucial for proper heat exchange and keeps the compressor from working itself to death.

Refrigerant Level Checks: They’ll make sure your refrigerant levels are exactly where they need to be. Low levels are a top cause of poor cooling and serious system strain.

Door Seal and Hinge Inspections: Experts will check gaskets for any tears and ensure doors seal up tight, preventing precious cool air from escaping.

These small, consistent actions make a huge difference. They lower your daily energy bills, help your equipment last longer, and give you solid, unwavering food safety. You can learn more about [how regular refrigeration maintenance can prevent major food loss](https://www.pmechanicalfl.com/post/how-regular-refrigeration-maintenance-can-prevent-major-food-loss) in our detailed article.

Long-Term Financial and Operational Benefits

Investing in proactive care is one of the smartest business decisions you can make. The global market for commercial refrigeration is massive—it's projected to hit $69.2 billion by 2035—which just goes to show how vital this equipment is for the entire food service industry. Protecting that investment is just good business.

Proactive maintenance is not an expense; it's an investment in operational stability. By preventing just one major breakdown, a maintenance plan can pay for itself several times over.

A solid preventative plan is the best way to keep your kitchen running without interruptions. A great place to start is by reviewing a [comprehensive commercial kitchen equipment maintenance guide](https://preptables.com/blogs/prep-tables/commercial-kitchen-equipment-maintenance). By scheduling regular service, you’re protecting your equipment, your inventory, and your peace of mind.

Common Questions About Refrigeration Repair

When your walk-in cooler starts acting up, you need answers, and you need them fast. A potential refrigeration emergency always brings up a flood of urgent questions about cost, speed, and what you can safely handle on your own.

Getting clear information is the first step to making a smart, confident decision when you're searching for "restaurant refrigeration repair near me." We've pulled together the most common questions we hear from restaurant owners facing an equipment breakdown to help you navigate the repair process with less stress.

How Much Does a Typical Repair Cost?

Trying to pinpoint an exact repair cost without seeing the unit is like a chef guessing a customer's order before they even sit down—it really depends on the situation. A simple fix, like replacing a thermostat, might only be a couple of hundred dollars. On the other hand, a major compressor failure on a large walk-in cooler could easily run into the thousands.

Several key factors will shape the final invoice:

Type of Unit: It costs a lot less to service a small under-counter prep cooler than it does to work on a massive walk-in freezer.

Parts Needed: There's a huge price difference between a new fan motor and a new compressor or evaporator coil.

Labor Rates: A technician’s hourly rate is a major factor. This can change based on their experience and whether you need them during regular hours or for an after-hours emergency call.

Accessibility: If your unit is crammed in a tight spot or hard to get to, it takes the technician longer to work, which can bump up the labor cost.

A transparent technician will always give you a detailed, itemized quote before they start any work. That quote should clearly break down the costs for parts, labor, and any trip fees so you know exactly what you’re paying for—no surprises.

Can I Do Any Repairs Myself?

When you’re staring at an unexpected expense, the temptation to roll up your sleeves and try a DIY fix is completely understandable. But commercial refrigeration systems are complex, high-pressure machines, and most repairs are strictly a job for certified pros.

Attempting a fix without the right training can easily lead to more expensive damage, create serious safety hazards, or even void your equipment's warranty.

There are, however, a few small maintenance tasks you can and absolutely should handle yourself:

Cleaning Condenser Coils: Gently brushing or vacuuming dust and debris from the coils can make a huge difference in efficiency.

Checking and Cleaning Gaskets: Wipe down your door seals and check them for cracks. A good seal keeps the cold air in where it belongs.

Clearing Drain Lines: Make sure your drain lines are free of clogs to prevent water from pooling all over your floor.

For anything more complicated—like electrical problems, refrigerant leaks, or motor issues—it is always best to call a professional. If you're wondering how professional maintenance fits in with your kitchen's other systems, you can learn more about how to [find reliable commercial HVAC maintenance near me](https://www.pmechanicalfl.com/post/find-reliable-commercial-hvac-maintenance-near-me).

How Fast Should an Emergency Technician Arrive?

When your main walk-in cooler dies on a Friday night, "fast" is the only thing on your mind. For a critical piece of equipment like that, the industry standard for an emergency response is typically within 2 to 4 hours. This window is designed to get a technician on-site before you start losing a significant amount of inventory.

Of course, a company's promised response time can vary. When you’re checking out a service provider, ask them directly what their guaranteed arrival window is for a true emergency. A reliable company that specializes in restaurant refrigeration understands the urgency. They’ll have systems in place to get technicians out the door quickly, especially for their existing clients. That rapid response is what separates a true emergency service from a standard repair company.

When a refrigeration emergency strikes, you need a partner you can count on. Putnam Mechanical LLC offers same-day emergency response to get your kitchen back in business fast, with upfront pricing and no hidden fees. Contact us today for immediate assistance.

_edited%20copy.png)