Trusted Commercial Refrigeration Repair Near Me

- Sep 11, 2025

- 11 min read

When your walk-in cooler gives out in the middle of a dinner rush, it’s not just an inconvenience—it's a full-blown crisis for your business. Finding a reliable and fast commercial refrigeration repair service isn't about convenience; it's about protecting your bottom line.

A quick fix can be the one thing that stands between a minor hiccup and thousands of dollars in spoiled inventory, potential health code violations, and a damaged reputation with your customers.

Why Quick Refrigeration Repair Is So Important

Every minute your commercial refrigeration is down, you're losing money and creating chaos. For a restaurant, a broken walk-in means service grinds to a halt. For a grocery store, a failing freezer case puts product at risk and shakes customer confidence.

The fallout goes beyond the immediate financial hit. A system breakdown can lead to some serious headaches:

Massive Inventory Loss: Perishables like meat, dairy, and produce don't last long at the wrong temperature. What was valuable stock can quickly become expensive waste.

Health and Safety Risks: Unsafe food temperatures are a breeding ground for bacteria, putting your business at risk for health code violations and, more importantly, endangering your customers.

Operational Disruption: When a critical piece of equipment fails, it can shut down your entire operation, impacting everything from staff productivity to your ability to serve anyone at all.

Good Technicians Are In High Demand

The need for skilled repair technicians is only growing. The global market for commercial refrigeration repair is on track to hit $25.8 billion by 2033, which just shows how vital these systems are for businesses everywhere. This trend highlights why having a qualified pro you can trust is more important than ever.

When you’re in a jam, knowing who to call makes all the difference. Our emergency commercial refrigeration repair guide offers practical advice for what to do when disaster strikes.

But before you even get to that point, it helps to know what to look for. Not all repair services are created equal, and in an emergency, you don't have time to vet dozens of companies.

Essential Qualities in a Refrigeration Repair Service

This quick table breaks down the non-negotiables you should expect from any technician you hire. Think of it as a checklist to protect your business.

Attribute | Why It's Critical for Your Business |

|---|---|

24/7 Availability | Refrigeration doesn't just fail between 9 and 5. You need a team that will answer the phone on a Saturday night or a holiday morning. |

Certified & Experienced | This isn't a job for a handyman. Technicians should be certified and have proven experience with your specific type of equipment. |

Fast Response Time | "We'll get there sometime tomorrow" isn't going to cut it. Look for companies that guarantee a quick response to minimize your downtime. |

Well-Stocked Service Vehicles | A technician who has to leave to get a common part is wasting your time and money. Their trucks should be stocked for the most frequent repairs. |

Choosing the right partner from the start means you’ll get a fast, professional fix that protects your assets and keeps your business running smoothly.

Finding and Vetting Local Repair Companies

When your walk-in cooler suddenly gives out, your first instinct is probably to grab your phone and search for "commercial refrigeration repair near me." That's a good start, but finding a truly reliable partner requires digging a little deeper than the first few results.

The best place to begin is by asking around. Talk to other local business owners—the restaurant down the street, the corner grocery store. Their firsthand experience is worth its weight in gold and can save you a ton of headaches. You can also check out industry-specific supplier networks, which often list pre-vetted pros who actually specialize in commercial systems. A company that invests in modern quality assurance processes is another good sign they're serious about delivering consistent, high-quality work.

Your Initial Call Checklist

Once you have a short list of potential companies, the first phone call is your chance to really vet them. Don’t just ask if they’re available; treat it like a mini-interview to see if they’re the right fit for your business.

Here are a few non-negotiable questions to ask:

Licensing and Insurance: Are your technicians fully licensed, and more importantly, can you email me proof of your liability insurance? This is crucial—it protects your business if something goes wrong during the repair.

Emergency Availability: What’s your actual response time for a weekend or after-hours emergency? A vague answer like "we'll get there when we can" is a massive red flag. You need commitment.

Brand Experience: My walk-in is a True (or Traulsen, or whatever brand you have). Do your techs have certified experience working on this specific brand? Specialized knowledge is key to avoiding a misdiagnosis and a repeat service call.

A restaurant owner in Sarasota I know recently vetted three companies this way. One couldn't produce proof of insurance, and another admitted they didn't offer weekend service. The third one answered every question confidently and had their credentials in his inbox within minutes. Guess who got the job?

This kind of proactive vetting and focusing on a company that values preventative care is the best way to keep your business running without costly interruptions.

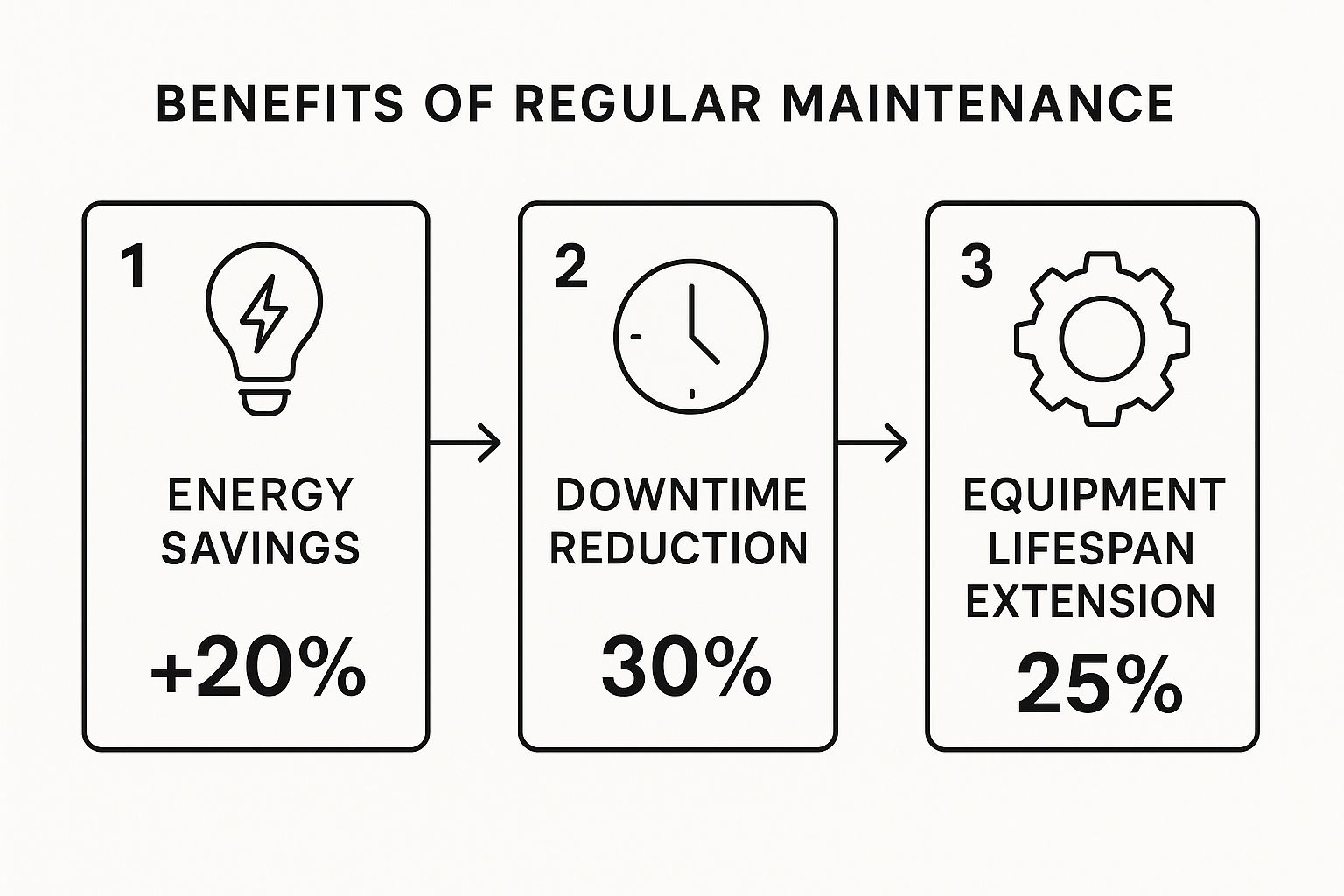

The image below really drives home how much proper maintenance—a key service offered by any top-tier repair company—can impact your bottom line.

As you can see, regular upkeep does more than just prevent breakdowns. It significantly cuts down your energy costs and extends the life of your equipment. Of course, even the best-maintained unit has a lifespan. If you suspect yours is on its last legs, it's worth learning more about https://www.pmechanicalfl.com/post/when-is-it-time-to-replace-your-restaurant-s-refrigeration-unit to help you make the right financial call.

Matching Technician Expertise to Your Equipment

Not all refrigeration systems are the same, and neither are the technicians who service them. You can't just hire a generalist and hope for the best. The skills needed for a small under-the-counter bar cooler are worlds away from what it takes to fix a sprawling, multi-compressor walk-in freezer or a high-tech blast chiller. Assuming any tech can handle any job is a surefire way to end up with repeat service calls and frustrating downtime.

Think of it this way: you wouldn't ask your family doctor to perform heart surgery. In the same way, a technician who isn't trained on your specific equipment brand—whether it’s a True, Traulsen, or Hoshizaki unit—could easily misdiagnose the problem. That leads to the wrong parts, the wrong fix, and bigger headaches down the road.

When you're searching for "commercial refrigeration repair near me," make it a point to ask about brand certifications and their direct experience with your type of equipment.

Why Specialization Saves You Money

A specialized technician gets it. They understand the unique engineering behind your equipment, know the common failure points, and come prepared with the right diagnostic tools and parts. The result? A faster, more accurate fix.

This kind of expertise is becoming more critical every day. The commercial refrigeration market is on track to hit nearly $79.38 billion by 2034, largely because of tech innovations like IoT-enabled systems that allow for remote monitoring. You can dig into more of these market trends over at PersistanceMarketResearch.com. A technician who isn't up to speed on these modern systems might just fix the symptom—like a temperature issue—without ever touching the real underlying electronic or software problem.

Hiring a technician with proven, specialized expertise is the single best way to ensure your equipment is fixed correctly the first time. It prevents the frustration and cost of having another company come out to fix the first repair.

Ultimately, spending a little more on a true specialist protects your much larger investment in the equipment itself. Proactive care from an expert who knows your system inside and out is always smarter—and cheaper—than scrambling for an emergency fix. To get ahead of problems, check out our guide on https://www.pmechanicalfl.com/post/how-often-should-you-schedule-maintenance-for-your-refrigeration-equipment.

Decoding Service Costs and Response Times

When your refrigeration unit goes down, two questions hit you immediately: "How much is this going to cost?" and "How fast can you get here?"

Getting a handle on the financial side of a service call is crucial. It helps you avoid surprise bills and lets you make a smart, quick decision when you're scrambling to find commercial refrigeration repair near me. Most companies structure their pricing in a few common ways, and knowing what to expect puts you in control.

Most technicians will start with a flat-rate diagnostic fee. This covers their time and travel to come to your location and figure out what’s wrong. Once they’ve pinpointed the problem, the repair cost is usually broken down into an hourly labor rate plus the cost of any parts needed to get you running again.

The most important thing you can do? Always ask for a detailed, written estimate before you give them the green light to start working. A reputable company will have no problem breaking down every line item for you.

Speed Versus Savings

In an emergency, the cheapest option is rarely the best one.

A service advertising a super-low hourly rate might not be available for 24 hours. By then, your entire inventory could be a total loss. This is where you have to stop thinking about the hourly rate and start thinking about the real cost to your business.

Paying a premium for a service that guarantees a two-hour emergency response can actually save you thousands. That slightly higher labor cost is a small price to pay compared to replacing an entire walk-in cooler full of spoiled product.

Think of it as an insurance policy. That extra expense for a 24/7 emergency service is a direct investment in protecting your most valuable assets.

Comparing Standard vs Emergency Repair Services

So, how do you decide what you need? Here’s a quick breakdown to help you understand the trade-offs between cost and speed, so you can make the right call for your business when a crisis hits.

Service Tier | Typical Response Time | Cost Structure | Best For |

|---|---|---|---|

Standard Service | 24-48 hours | Lower hourly rates, standard diagnostic fees | Non-critical issues, scheduled maintenance, minor repairs |

Emergency Service | 1-4 hours (24/7) | Higher hourly rates, premium after-hours fees | Critical failures, inventory at risk, operational shutdown |

When it comes down to it, choosing a repair service based on price alone can be a costly mistake. Prioritizing a company with a guaranteed rapid response time isn't just an expense—it's an investment in your business's survival.

The Hidden Value of a Maintenance Plan

Let’s be honest, the best repair is the one you never have to make. Shifting from a reactive, “call when it breaks” mindset to a proactive one isn't just a small adjustment—it's a serious investment in your business's future. A preventative maintenance plan turns a potential weekend-ruining catastrophe into a predictable, manageable operating cost.

Instead of just waiting for the worst to happen, a quality maintenance contract puts regular check-ups on the calendar. These aren’t just quick glances; technicians perform detailed tasks that are absolutely essential for keeping your equipment running at peak performance and extending its life.

What Quality Maintenance Actually Looks Like

When a technician shows up for routine maintenance, they’re on the hunt for small issues that could turn into big, expensive headaches.

Coil Cleaning: Dirty condenser and evaporator coils make the compressor work way harder than it should. This burns through electricity and is a leading cause of premature failure.

Refrigerant Level Checks: If your refrigerant is low, you have a leak—plain and simple. Catching it early stops a minor fix from becoming a complete system failure and a massive bill for new refrigerant.

Electrical Component Testing: Technicians inspect all the important electrical parts like wiring, contactors, and motors for wear and tear. This helps prevent those sudden electrical failures that can shut down your entire unit without warning.

Imagine a grocery store heading into a huge holiday weekend. During a routine check, the maintenance tech spots a fan motor that's on its last legs. He replaces it that afternoon. That simple fix prevented a guaranteed breakdown during the holiday rush, saving the store from thousands in emergency repair fees and spoiled inventory.

A Global Standard for Protecting Your Business

Taking care of equipment before it breaks is a globally recognized best practice. The demand for reliable commercial refrigeration repair near me is skyrocketing, driven by strict food safety regulations and the growing complexity of modern cooling systems. With smart sensors and predictive tech becoming more common, proactive maintenance is more critical than ever to keep downtime to a minimum.

For any business that relies on refrigeration, proactive care is the only way to operate. It’s the key to preventing those costly, business-halting breakdowns. To dig deeper, check out these expert insights on mastering commercial kitchen equipment maintenance.

Ultimately, a good maintenance plan doesn't just fix problems—it stops them from ever happening. You can learn more about [how regular maintenance prevents costly equipment breakdowns](https://www.pmechanicalfl.com/post/how-regular-maintenance-prevents-costly-equipment-breakdowns) in our detailed guide.

Common Questions About Refrigeration Repair

When your walk-in freezer is on the fritz, you don’t have time for a long research project. You need clear answers, and you need them fast. Dealing with an unexpected equipment failure is stressful enough, but having the right information can help you make smart, cost-effective decisions without losing your cool.

Here are the direct answers to the most common questions we hear from business owners looking for a "commercial refrigeration repair near me."

How Do I Know If My Refrigeration Problem Is an Emergency?

It’s an emergency if the problem directly threatens your inventory, customer safety, or your ability to operate. Some issues can’t wait until morning—they demand immediate attention to stop a small problem from snowballing into a catastrophic loss.

You’ve got a true emergency on your hands if you notice:

Rapidly Rising Temperatures: If your cooler's internal temperature climbs above 40°F or your freezer starts to thaw, it's a critical situation. Every minute counts.

Loud, Unusual Noises: Grinding, screeching, or banging sounds are never good. They often signal a failing compressor or fan motor, components that can cause a complete system breakdown.

Strong Chemical Smells or Visible Leaks: That distinct chemical odor could be a refrigerant leak. This is not only bad for your system but is also a health hazard that requires a certified technician to handle safely.

Don't second-guess a full system failure. For any food-based business, a unit that has stopped cooling entirely is always an emergency. That's the time to call a 24/7 repair service, no questions asked.

Should I Try to Fix the Commercial Unit Myself?

Unless you’re just checking that the unit is plugged in or the circuit breaker hasn’t tripped, the answer is a firm no. Commercial refrigeration systems are a different beast entirely compared to your fridge at home. They run on high-pressure refrigerants and are packed with intricate electrical components that pose a real safety risk to anyone who isn't a licensed pro.

A DIY repair attempt can easily backfire, leading to more expensive damage, voiding your equipment's warranty, or even causing serious injury. To get a better sense of what to look for, check out our guide on signs your refrigeration system needs immediate attention. Your best and safest bet is to always call a certified technician.

What Information Should I Have Ready When I Call for Service?

You can help us help you faster by having a few key details ready. When you have this information on hand, it helps the dispatcher understand the situation and ensures the technician arrives with the right tools and potential parts for the job.

Before you pick up the phone, try to gather this info:

Equipment Make and Model: Look for a metal tag, usually inside the door jamb or on the side of the unit.

A Clear Description of the Issue: Be specific. Instead of just saying "it's broken," try something like, "it's making a loud humming noise and the temperature has climbed to 50°F."

The Unit's Current Temperature: If you can safely get a reading, this is incredibly helpful for an initial diagnosis.

A little bit of prep goes a long way in getting the repair process started smoothly and efficiently.

When you need reliable, fast commercial refrigeration repair, trust the experts at Putnam Mechanical LLC. We offer same-day emergency service to get your business back up and running with transparent, upfront pricing. Contact us today for immediate assistance at https://pmechanicalfl.com.

_edited%20copy.png)