How to Check Circuit Breaker Is Bad: Easy Step-by-Step Guide

- Putnam Mechanical

- Sep 5, 2025

- 15 min read

Sometimes, you can spot a bad circuit breaker without touching a single tool. If a breaker trips instantly after a reset, feels hot, or has obvious damage like scorch marks, the breaker itself is probably the culprit.

Key Signs Your Circuit Breaker Is Failing

Before you even think about opening up the electrical panel, just take a moment to look and listen. A failing circuit breaker often gives you clear warnings that something is wrong internally. Think of it as a quick visual inspection—your eyes, nose, and even your sense of touch are the first tools you'll use.

The most common red flag? A breaker that simply won't stay reset. You flip it to "ON," and it immediately clicks back to the tripped or "OFF" position, even when nothing is plugged into that circuit. This isn't your typical overload; it’s a big clue that you're dealing with an internal fault or a serious short circuit.

Physical and Visual Warnings

A healthy circuit breaker shouldn't feel warm, let alone hot. If you hover your hand over the panel and one breaker is noticeably warmer than the others, that's a serious problem. Heat is a sign of high resistance or a bad connection inside the breaker, which is a major fire risk.

A burning smell—often like burnt plastic or that distinct electrical "ozone" scent—coming from your panel is an emergency. It’s one of the most urgent signs of a failing breaker or dangerous wiring that needs immediate, professional attention.

Another dead giveaway is visible damage. Take a close, careful look at the breaker. You’re looking for things like:

Scorch Marks: Any black or brown stains on or around the breaker mean it has been overheating and arcing.

Melted Plastic: If the casing looks warped or melted in any way, it's been exposed to dangerous levels of heat.

Frayed Wires: Check the wire connected to the breaker. If its insulation is cracked, burnt, or frayed, you've found a problem.

A Loose Switch: The breaker's switch should feel solid. If it’s wobbly or doesn’t snap firmly into place, it’s worn out and needs to be replaced.

A quick visual inspection can often tell you if you're dealing with a faulty breaker or a larger issue on the circuit. This is a lot like how we approach complex systems; consistent checks are just as vital for your electrical panel as they are for commercial refrigeration. You can learn more about why these routine checks matter in our guide on scheduling maintenance for refrigeration equipment.

Quick Guide to Bad Circuit Breaker Symptoms

When you're trying to diagnose a problem quickly, it helps to have a simple reference. Here are the most common signs that point to a bad circuit breaker and what you should do about them.

Symptom | What It Likely Means | Your Next Step |

|---|---|---|

Instantly Trips | The breaker has an internal fault or there's a serious short circuit. | Turn off the main breaker and call an electrician immediately. |

Hot to the Touch | There's high resistance or a poor connection, creating a fire hazard. | Do not touch it again. Contact a professional electrician right away. |

Burning Smell | A component is overheating, melting, or arcing. This is a fire risk. | Shut off the main power if safe and call for emergency electrical service. |

Visible Damage | The breaker has already failed due to overheating or an electrical fault. | The breaker is compromised and must be replaced by a qualified person. |

Loose or Wobbly Switch | The internal mechanism is worn out and can no longer function reliably. | The breaker is at the end of its life and needs to be replaced. |

These symptoms are your electrical system’s way of warning you. Paying attention to them is the first and most important step in keeping your property safe.

Gathering Your Tools and Safety Gear

Working inside an electrical panel isn't something you can just wing. Before you even think about taking off that panel cover, you absolutely have to get the right tools and—even more critically—the proper safety gear. Getting this part right sets you up for a safe and successful diagnosis.

The single most important tool for this job is a reliable digital multimeter. It’s the only way to get a hard reading and know for sure if a breaker has failed on the inside. Sure, analog multimeters are out there, but a digital model gives you a crystal-clear measurement, taking all the guesswork out of the equation.

Along with your multimeter, you’ll need a few other essentials. Insulated screwdrivers are a must-have for safely removing the panel cover. Their rubberized handles are specifically designed to protect you from a nasty shock if you happen to touch a live part. A good flashlight or headlamp is also a game-changer, since breaker panels always seem to be tucked away in a dark basement or closet.

Your Personal Protective Equipment Checklist

Let's be clear: Personal Protective Equipment (PPE) isn't just a good idea—it's your first line of defense against getting seriously hurt. Electrical work comes with unique risks, and your gear needs to be up to the task.

Safety Glasses: These will protect your eyes from sparks or debris if a breaker unexpectedly arcs.

Insulated Gloves: Make sure you get gloves specifically rated for electrical work. They create a crucial barrier between you and any live current.

Sturdy Footwear: Always wear rubber-soled shoes. They provide another layer of insulation between you and the ground.

Knowing what gear to use is a huge part of electrical safety. It helps to understand the official Personal Protective Equipment (PPE) requirements, especially when electricity is involved. This ensures you're not just wearing gear, but the right gear.

Safety First Pro-Tip: Never, ever work on an electrical panel while standing on a wet floor or wearing damp clothes. Water is an incredible conductor of electricity, and mixing the two drastically increases your risk of severe electric shock.

Creating a Safe Work Environment

Once you have your tools and PPE ready, the last thing to do is make sure your workspace is safe. Start by shutting off the main circuit breaker, which cuts power to the entire panel. This should de-energize the whole box, but you can't just assume it did. You have to verify it.

After flipping the main breaker, grab a non-contact voltage tester and confirm there’s no power at any of the individual breakers. It’s a simple check that can save your life. This kind of disciplined, step-by-step preparation is what the pros do. In fact, it's the same logic behind why https://www.pmechanicalfl.com/post/how-regular-maintenance-prevents-costly-equipment-breakdowns is so effective—careful, systematic procedures prevent disaster. By prepping properly, you're putting safety first before moving on to the actual test.

Conducting a Thorough Visual Inspection

You'd be surprised what you can spot just by looking at a circuit breaker. Before you even think about grabbing any tools, a careful visual scan can tell you a lot about its health. This first pass is all about spotting the subtle clues that something might be wrong.

Of course, the absolute first step is safety. Always shut off the main power before opening up the panel. Once it's de-energized, you can get to work.

Checking the Plastic Casing for Cracks

Start by looking closely at the breaker's outer plastic shell. You're searching for any fine fractures or splits. Even a hairline crack can be a sign of internal stress from heat or physical damage. I once had a client who found a tiny split near the switch on a constantly tripping breaker—that was the giveaway.

Also, keep an eye out for any discoloration. If the plastic looks yellowed or has a brownish tint, that’s a classic sign of overheating. It means the breaker has been getting way too hot for a long time.

Looking for Soot and Corrosion

Next, grab a flashlight and look for anything that shouldn't be there. Dark, sooty residue around the terminals is a tell-tale sign of arcing, which means the electrical connection is poor and dangerous.

You might also see:

White or green buildup, which points to corrosion from moisture getting inside the panel.

Scorch marks on the breaker or the bus bars it connects to. This is a serious issue that needs a professional's attention immediately.

Inspecting Terminals and Connections

Lean in and take a good look at where the wires connect to the breaker. A loose or discolored terminal lug is a common source of problems because it creates high resistance and heat.

Give each wire a gentle tug. It should feel completely solid. If there’s any wiggle room, that connection isn't secure. And if you catch a faint whiff of burnt plastic? That's a major red flag. That smell often appears long before you can see any visible damage.

While you're at it, check the breaker itself. It should sit snugly in its slot. If it has any side-to-side play, the internal mechanism might be compromised. When you flip the switch (with the power still off!), listen for a crisp, clean snap. A mushy or weak-feeling switch is another bad sign.

Assessing Equipment Age and History

It’s always a good idea to check the manufacture date, which is usually stamped right on the breaker. Breakers, especially older ones, don't last forever. A recent CIGRE reliability survey found that breakers over 40 years old have a much higher failure rate.

You can learn more about these circuit breaker reliability findings in the full report. While modern breakers have low major failure frequencies, those vintage ones are often living on borrowed time.

“Always pair your visual findings with documented service records to paint a complete health picture.”

Understanding how your equipment's age and maintenance history affect performance is key. If you're managing a business, this applies to everything from your electrical panel to your walk-in cooler. Our guide on commercial appliance repairs for your business dives deeper into this.

Documenting Your Findings

While the panel is still safely de-energized, pull out your phone and take pictures of anything that looks off. Be sure to get clear shots and maybe even date-stamp them for your records.

Jot down some quick notes, too. A simple clipboard will do. Write down the breaker's position or ID, what you observed, and what you think the issue might be. This simple record-keeping can be a huge help for any technician you call, speeding up the repair process.

A pro tip is to use colored labels or tape to tag any breakers that look suspicious. Your future self—or the electrician you hire—will thank you for making it so easy to find the problem area again.

Real-World Case Study

We worked with a restaurant manager in Sarasota who smelled something burning near his electrical panel. He did a quick visual check and spotted some brownish streaks on a breaker and noticed one of the terminal lugs was loose.

He took photos and sent them to us. Because we had that information upfront, our technician arrived with the right replacement breaker in hand. That simple inspection saved the restaurant hours of costly downtime.

Technicians we’ve talked to estimate that a good inspection checklist can cut diagnostic time by up to 30%.

With detailed notes and photos from your visual check, you’ll be in a much better position to decide if a breaker just needs to be replaced or if there’s a bigger issue hiding in your panel.

Testing a Circuit Breaker With a Multimeter

Sometimes, a breaker looks fine on the outside, but it’s a different story internally. When a visual check isn't enough, grabbing a digital multimeter will give you the hard proof you need to know if it's good or bad. By setting your multimeter to continuity or Ohms, you're getting it ready to see if current can actually flow through the breaker like it's supposed to.

With the breaker in the ON position, you’ll place one probe on the line terminal (where power comes in) and the other on the load terminal (where power goes out). This simple test tells you if the circuit is truly complete or if there's a hidden break inside, even though the switch is flipped on.

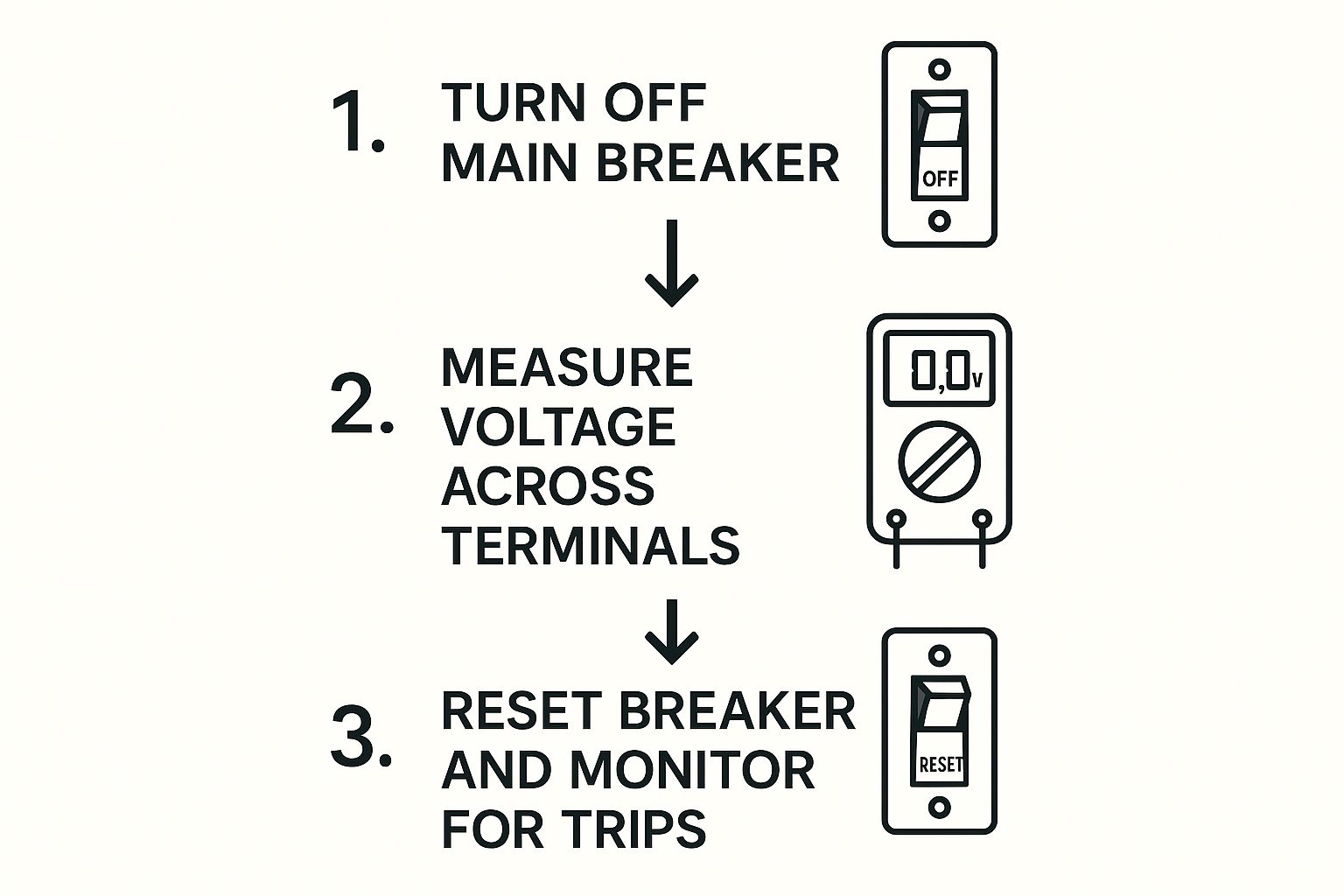

This infographic breaks down the basic workflow into three simple stages.

As you can see, the process is straightforward: shut off the main power, test the individual breaker, and then reset everything while watching for any issues.

Prepare Your Multimeter And Panel

Safety first, always. Before you touch anything inside the panel, shut off the main breaker. This de-energizes the entire box. Even then, double-check that the power is off with a non-contact voltage tester before proceeding. This step is non-negotiable.

Once you’ve confirmed the panel is dead, set your multimeter to its lowest Ohms (Ω) setting or to the continuity mode (it usually has a sound icon). A healthy, closed circuit will give you a reading close to 0 Ω or trigger a beep.

Always wear insulated gloves and safety glasses.

Make sure your multimeter probes aren't frayed or damaged.

Check the panel’s legend to be sure you’re about to test the correct breaker.

Detecting Open Circuits And Shorts

With the panel safely de-energized, take the red probe and touch it to the load terminal (the screw where the wire leaves the breaker), and place the black probe on the line terminal. If the breaker is switched ON, you should get a steady reading of 0 Ω. That means the internal connection is solid.

If your multimeter displays "OL" (Overload or Open Line) or you don't hear a beep on the continuity setting, the breaker is internally open. It's blocking current even when it’s supposed to be letting it through. That’s a clear sign of a bad breaker.

First, test for continuity with the breaker in the ON position.

Next, flip it to OFF to confirm the circuit is broken (you should see OL).

Gently wiggle the breaker’s handle while testing. This can reveal intermittent faults that a static test might miss.

I’ve seen plenty of breakers that test fine until you give them a little wiggle. That movement can expose worn-out internal contacts or a weak mechanical connection. If you see the resistance jump around as you do this, you’ve found a problem.

In fact, field experience and industry studies show a surprising 15% failure rate during routine breaker maintenance checks. It really drives home why this kind of hands-on testing is so critical. You can learn more from this research on Testing and Exercising Circuit Breakers.

Analyze Resistance Trends

For breakers on critical equipment, it’s a good idea to track their health over time. A single good reading is one thing, but a trend tells a much bigger story. A reading that slowly creeps up from 0.05 Ω to 0.2 Ω over several months is a red flag for internal corrosion or pitting on the contacts. This lets you spot a failing breaker before it completely dies.

Measure the breaker’s resistance periodically, especially after it’s been under heavy load.

Keep a simple log or spreadsheet to see the trend lines clearly.

Flag any breaker with a resistance consistently above 0.1 Ω for a closer look or replacement.

Interpreting Results And Next Steps

So, what do the numbers mean? A solid 0 Ω reading in the ON position is great—it suggests the breaker is mechanically sound. However, if you notice it’s slow to trip under fault conditions, the internal components might be aging.

An OL reading while the breaker is ON is definitive: it's an open circuit. The breaker is toast and needs to be replaced to keep the system safe. Make sure you clearly label any breaker you’ve identified as faulty so it doesn't get used by mistake.

A breaker that trips too slowly—or worse, fails to trip at all—is a serious safety hazard. These are unmistakable signs that its internal mechanisms have worn out.

When you replace a bad breaker, use one with the exact same type and amp rating. No substitutions.

After installing a new breaker, test it under a real load before you close the panel back up.

If you find several bad breakers in the same panel, it’s probably time to call a licensed electrician for a full panel inspection.

I always recommend having a spare set of multimeter probes in your tool bag. It’s a small thing, but it can save a ton of time and prevent testing errors from a bad lead. If you’re ever unsure about a reading or a breaker just isn’t acting right, stop what you’re doing and call in a pro.

Proper testing like this can cut your diagnostic time by up to 30%, letting you swap out bad breakers and get your system protected that much faster.

Understanding the Results and What to Do Next

Alright, you've done the visual check and have the multimeter readings. Now for the most important part: connecting the dots to figure out what's really going on with your circuit breaker. The numbers and observations you've gathered tell a story.

For instance, if your multimeter screamed 'OL' (Open Line) or showed a super high resistance reading when the breaker was flipped ON, that's a dead giveaway. The connection inside is broken, and it can't do its job anymore. That breaker needs to be replaced, period. On the flip side, if you tested a breaker in the OFF position and still heard a continuity beep, you've got a dangerous internal short.

Deciding Between DIY Replacement and Calling a Pro

What you do next hinges entirely on what you found. A simple swap of one bad breaker for a new one can be a manageable DIY task—if you're experienced and comfortable working with electricity.

But some discoveries are absolute red flags. These are signs of a much bigger, more dangerous problem that a single new breaker won't fix. If you see any of these, it's time to stop and call a pro.

When to Call a Professional Electrician:

Burn marks on the bus bar: Scorch marks on that metal bar the breaker clips onto mean there's been serious arcing. This poor connection has probably damaged the panel itself.

Multiple failing breakers: Finding two or more bad breakers isn't just bad luck. It often points to a larger problem like a power surge that cooked them or a failing electrical panel.

A strong burning smell: That unmistakable smell is an active warning sign. Something is overheating right now, and you need an expert to diagnose it immediately.

Any signs of water or corrosion: Moisture inside an electrical panel is an emergency. It’s an urgent fire and shock hazard that needs a professional eye.

These situations are no place for guesswork. The safety of your home and family is what matters most.

The Lifespan and Reliability of Circuit Breakers

It helps to remember that breakers, while tough, don't last forever. They work hard for decades, but eventually, they wear out. A comprehensive reliability study found the average time between failures for a breaker assembly is about 21.9 years.

This means they can chug along reliably for over two decades before a failure gets more likely. Key components start showing failure rates anywhere from 1.69 to over 2.3 failures per million cycles.

A single faulty breaker is a component failure. Multiple issues or damage to the panel itself suggest a system-level problem. Knowing the difference is key to a safe resolution.

Sometimes, the breaker is actually doing its job perfectly, but an appliance is the real culprit. A failing compressor in a big AC unit, for example, can cause repeated trips. This is really common in commercial buildings where systems are under constant strain; our essential commercial HVAC maintenance checklist can help pinpoint those kinds of issues.

In those cases, the breaker isn't the problem—the appliance is. When you've traced the issue to a specific piece of equipment, calling in appliance repair experts is the right move. By correctly interpreting your test results, you can move from diagnosis to a safe, effective solution.

Common Questions About Faulty Circuit Breakers

Even after running a few tests, you might still have some questions floating around about how to check if a circuit breaker is bad. Let's clear up a few of the most common ones I hear from homeowners. Getting these answers straight can give you the confidence to figure out your next move.

One of the biggest head-scratchers is whether a breaker can go bad without actually tripping. The answer is a definite yes. A breaker can fail internally in what we call an "open" state. This means it cuts power to the circuit, but the switch itself is still physically in the "ON" position. This is usually what’s happening when a whole room or a single outlet just dies for no apparent reason.

Even more concerning, a breaker can fail in a way that prevents it from tripping during an overload or a short circuit. This is a huge problem. That little switch is supposed to be your safety net, but when it fails like this, it becomes a serious fire hazard. This is exactly why a multimeter test is so important—just looking at the panel won't tell you if a breaker has failed this dangerously.

Differentiating Breaker Types

People also get tripped up by the different kinds of breakers out there—standard, AFCI, and GFCI. They all look similar, but they protect against very different things.

Standard Breaker: Its only job is to protect your home's wiring from drawing too much current (overloads) and from short circuits. Simple and effective.

AFCI (Arc Fault Circuit Interrupter): This one does everything a standard breaker does, but it also listens for the dangerous electrical arcs that are a top cause of house fires.

GFCI (Ground Fault Circuit Interrupter): This breaker is all about protecting people from electric shock. It senses ground faults and is required in areas where water is nearby, like your kitchen, bathrooms, and garage.

Knowing the difference is key, especially when you’re troubleshooting an issue in a specific part of the house. If your kitchen outlets keep dying, a GFCI breaker could be the culprit. If a large appliance like an air conditioner is acting up, it could be tied to its dedicated circuit. You can get a better sense of how pros tackle these issues by learning what our commercial AC repair services include when diagnosing system-specific electrical problems.

Considering Replacement Costs

Of course, the big question is always about cost. The price to swap out a circuit breaker can swing quite a bit, depending on the type of breaker and whether you call in a professional.

A standard single-pole breaker is pretty cheap—maybe $5 to $15 for the part. But once you hire a licensed electrician, you're looking at a total cost between $125 and $250 to cover their service call, labor, and the part itself.

If you need a specialized breaker, like an AFCI or GFCI model, the part itself is more expensive. The final bill can also climb if the electrician opens up your panel and finds other underlying problems that need to be fixed to keep things safe.

When your business's critical systems face electrical issues, you need reliable experts. At Putnam Mechanical LLC, we provide specialized commercial HVAC and refrigeration services to keep your operations running smoothly. Find out how we can help at https://pmechanicalfl.com.

_edited%20copy.png)