Essential Commercial HVAC Maintenance Checklist for Optimal Performance

- Aug 25, 2025

- 14 min read

Commercial HVAC systems are the silent workhorses of any business, ensuring comfort, safety, and operational continuity. However, neglecting their upkeep can lead to staggering energy bills, unexpected breakdowns, and costly emergency repairs that disrupt your operations. A proactive approach isn't just recommended; it's essential for protecting your investment and maintaining a productive, comfortable environment for employees and customers alike. Waiting for a problem to arise is a costly gamble that can impact everything from inventory to revenue.

This comprehensive commercial HVAC maintenance checklist breaks down the most critical tasks into actionable, scheduled steps. By following this guide, facility managers and business owners can shift from a reactive 'fix-it-when-it-breaks' model to a strategic, preventive maintenance plan. This structured approach saves significant money, enhances system longevity, and guarantees peak performance year-round.

We will detail the essential checks needed for everything from air filters and coils to refrigerant levels and control systems. This guide provides the framework you need to build a robust maintenance schedule, prevent catastrophic failures, and keep your system running at maximum efficiency. Let's dive into the eight key areas that demand your attention for a healthy, reliable HVAC system.

1. Air Filter Inspection and Replacement

The air filter is the first line of defense for your entire commercial HVAC system. Its primary role is to capture airborne contaminants like dust, pollen, and debris before they can enter the system, clog components, and degrade indoor air quality. Neglecting this simple yet critical task forces the system to work harder, increasing energy consumption and accelerating wear and tear on vital parts like the fan motor and coils. This is a foundational step in any effective commercial HVAC maintenance checklist.

Why It's a Top Priority

A dirty, clogged filter restricts airflow, leading to a cascade of problems. Reduced airflow can cause your evaporator coils to freeze over, potentially damaging the compressor, one of the most expensive components to replace. Furthermore, poor filtration allows contaminants to accumulate on internal components, reducing efficiency and creating a breeding ground for mold and bacteria, which negatively impacts occupant health and productivity.

Practical Implementation and Examples

Different commercial environments have unique needs that dictate their filter maintenance schedules.

Corporate Offices: In a high-occupancy office building, filters may require inspection monthly and replacement quarterly to manage dust and allergens effectively.

Manufacturing Facilities: A factory with airborne particulates may use a two-stage system with disposable pre-filters changed weekly and more robust final filters replaced every few months.

Hospitals and Clinics: These facilities adhere to strict protocols, using high-efficiency particulate air (HEPA) filters that are changed on a rigorous, documented schedule to ensure patient safety and compliance.

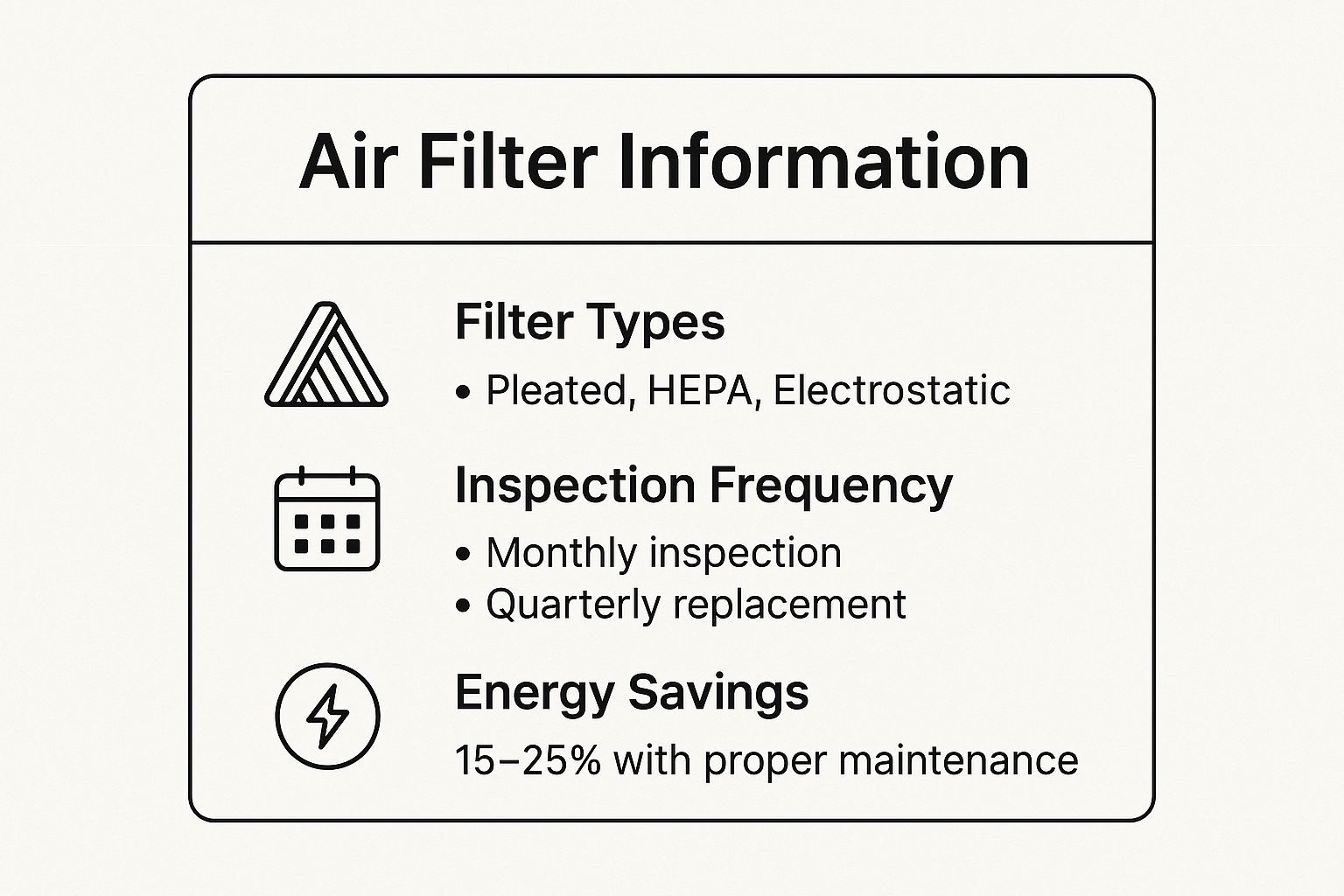

The following infographic summarizes the core principles of effective air filter management.

As the data highlights, a simple commitment to a monthly inspection and timely replacement can yield significant energy savings, directly impacting your operational budget.

Pro Tip: Keep a detailed log either digitally or physically on the air handler unit. Record the date of each filter change, the filter's specifications (size and MERV rating), and the initials of the technician. This practice ensures consistency and provides a valuable maintenance history.

2. Coil Cleaning and Inspection

Evaporator and condenser coils are the heart of your HVAC system's heat exchange process, responsible for absorbing heat from inside your building and releasing it outside. Over time, these coils accumulate dirt, dust, grease, and other debris, which acts as an insulator and severely impedes their ability to transfer heat effectively. A comprehensive coil cleaning and inspection is a non-negotiable part of any commercial HVAC maintenance checklist, ensuring the system runs efficiently and reliably.

Why It's a Top Priority

Dirty coils force the compressor to work harder and longer to achieve the desired temperature, leading to a significant increase in energy consumption and utility costs. This added strain accelerates wear on the compressor and other critical components, drastically increasing the risk of premature failure. Furthermore, dirty evaporator coils can become a breeding ground for mold and bacteria, which are then circulated throughout your facility, compromising indoor air quality and occupant health. Understanding how regular maintenance prevents costly equipment breakdowns is key to appreciating the value of this task.

Practical Implementation and Examples

The required frequency and intensity of coil cleaning vary based on the operating environment and its specific challenges.

Restaurant Chains: Kitchen exhaust and airborne grease require aggressive, quarterly coil cleaning schedules to prevent thick buildup that can completely block airflow and cause system failure during peak business hours.

Data Centers: These facilities depend on precise temperature control to protect sensitive IT equipment. Even a thin layer of dust can compromise cooling, so specialized, often low-moisture, coil cleaning is performed semi-annually to maintain peak performance and prevent overheating.

Retail Stores: Located in high-traffic areas, these stores typically schedule deep coil cleaning in the spring and fall to prepare the system for the heavy cooling and heating demands of the upcoming seasons.

Regular, professional cleaning restores heat transfer efficiency, directly lowering your operational expenses and extending the lifespan of your equipment.

Pro Tip: Always document coil condition with before and after photos for maintenance records. This visual evidence is invaluable for tracking performance, justifying maintenance expenditures, and identifying recurring issues that may point to environmental problems needing correction.

3. Belt and Motor Inspection

The belts and motors are the heart and muscle of your HVAC system's air handler, driving the fans that circulate conditioned air throughout your facility. Over time, belts can stretch, crack, or misalign, while motors can suffer from bearing wear and electrical issues. A proactive inspection of these components is essential to prevent catastrophic failures, maintain optimal airflow, and avoid the energy waste associated with an inefficient system. This task is a non-negotiable part of any comprehensive commercial HVAC maintenance checklist.

Why It's a Top Priority

A failing belt or motor can bring your entire HVAC operation to a sudden halt, leading to costly emergency repairs and significant business disruption. A loose belt reduces fan speed, diminishing airflow and system efficiency, while an overly tight belt puts excessive strain on motor bearings, leading to premature failure. Worn motor components can increase energy consumption, produce disruptive noise, and pose a potential fire hazard, making regular inspections a critical safety and operational measure.

Practical Implementation and Examples

The approach to belt and motor maintenance varies depending on the facility's operational demands and technological capabilities.

Office Buildings: During quarterly preventive maintenance visits, technicians typically perform a visual inspection of belts for wear, check tension with a gauge, and listen for unusual motor noises.

Shopping Malls: These large facilities may implement motor current signature analysis (MCSA) to detect subtle electrical imbalances that signal impending motor failure, allowing for planned replacement during off-hours.

Manufacturing Plants: In environments where system uptime is paramount, predictive maintenance tools like vibration analysis are often used to monitor motor and bearing health in real-time, catching problems long before they cause a shutdown.

Implementing these preventive maintenance best practices ensures your system operates with maximum reliability and efficiency.

Pro Tip: Always replace belts in matched sets, even if only one appears worn. A new belt paired with older, stretched ones will create an imbalance, putting uneven stress on the motor shaft and bearings, which can accelerate wear and lead to premature failure of all components.

4. Thermostat and Controls Calibration

Your HVAC system’s controls and thermostats are the brain of the entire operation, dictating when and how the equipment runs. Systematic calibration ensures these components receive accurate information and send the correct commands, preventing energy waste and maintaining occupant comfort. Neglecting this crucial task is like having a perfectly tuned engine with a faulty steering wheel; the system may function, but it won't operate efficiently or provide the desired results. This step is a cornerstone of any modern commercial HVAC maintenance checklist.

Why It's a Top Priority

An uncalibrated thermostat, off by just a few degrees, can cause the HVAC system to run excessively or shut off prematurely, leading to significant energy waste and uncomfortable temperature swings. Inaccurate sensors can trigger false alarms or fail to respond to actual environmental changes, compromising both efficiency and safety. For sophisticated Building Automation Systems (BAS), precise calibration is essential for leveraging advanced features like load shedding, economizer modes, and occupancy-based scheduling, which are key to minimizing operational costs.

Practical Implementation and Examples

The complexity of HVAC controls varies widely, requiring a tailored approach to calibration and testing across different commercial settings.

Corporate Headquarters: A modern office may use smart thermostats with occupancy sensors to adjust temperatures in unused zones. Calibration involves verifying both temperature accuracy and the responsiveness of the occupancy sensors to prevent heating or cooling empty rooms.

School Districts: These facilities often rely on centralized control systems to manage energy use across multiple buildings. Maintenance includes verifying that programmed schedules for holidays and weekends are active and that individual classroom sensors are communicating correctly with the central unit.

Healthcare Facilities: Hospitals maintain strict temperature and humidity levels in sensitive areas like operating rooms. Here, calibration is a compliance issue, requiring technicians to use certified instruments to verify and document that all sensors meet rigorous healthcare standards.

Pro Tip: Always verify sensor accuracy against a calibrated, independent testing instrument rather than relying on another sensor in the system. Document every programming change, update, and calibration result in a centralized log. This creates an invaluable performance history for future troubleshooting and optimization.

5. Ductwork Inspection and Sealing

The ductwork is the circulatory system of your commercial HVAC, responsible for delivering conditioned air efficiently to every corner of your facility. Often hidden above ceilings and behind walls, leaks, damage, and poor insulation in this network can lead to significant energy waste and comfort issues. A thorough inspection and sealing protocol is a vital component of any comprehensive commercial HVAC maintenance checklist, preventing conditioned air from escaping into unconditioned spaces like attics and plenums.

Why It's a Top Priority

Leaky ductwork forces your HVAC system to run longer and work harder to achieve the desired temperature, directly increasing utility bills. According to ENERGY STAR, the typical commercial building can lose 20-30% of the air that moves through its duct system to leaks, holes, and poor connections. This not only wastes energy but also creates pressure imbalances, introduces dust and pollutants into the building, and leads to inconsistent temperatures and occupant complaints. You can learn more about how damaged ductwork impacts your HVAC system's efficiency to better understand these risks.

Practical Implementation and Examples

The approach to ductwork maintenance can vary significantly based on the facility's design and use. A proactive strategy ensures both comfort and efficiency.

Office Buildings: A multi-story office seeking ENERGY STAR certification might perform a duct blaster test to quantify leakage and then systematically seal all accessible joints with mastic, achieving a 15% reduction in heating and cooling costs.

Retail Stores: To solve issues of "hot and cold spots," a retail chain could inspect duct insulation and repair damaged sections, ensuring consistent comfort across large, open-plan sales floors.

Warehouses: A large distribution center can significantly reduce its massive heating expenses by sealing major leaks in its extensive overhead ductwork and ensuring all sections are properly supported and insulated.

Pro Tip: Use thermal imaging cameras while the HVAC system is running to quickly and accurately identify significant air leaks and areas with failed insulation. This technology allows technicians to prioritize repairs on the most problematic sections first for the greatest immediate impact.

6. Refrigerant Level and Leak Detection

The refrigerant is the lifeblood of your HVAC system’s cooling cycle, responsible for absorbing and releasing heat to cool your commercial space. Proper refrigerant levels are essential for optimal performance, and even a small leak can significantly degrade efficiency, increase energy costs, and cause severe damage to critical components like the compressor. Verifying refrigerant charge and performing diligent leak detection are non-negotiable tasks in any thorough commercial HVAC maintenance checklist.

Why It's a Top Priority

An undercharged system cannot cool effectively, forcing it to run longer cycles to meet thermostat demands, which drives up utility bills. Conversely, an overcharged system can cause liquid refrigerant to flood the compressor, leading to catastrophic failure. Refrigerant leaks also pose a serious environmental risk, as many older refrigerants are potent greenhouse gases. Proactive leak detection and repair are crucial for both operational efficiency and environmental compliance.

Practical Implementation and Examples

The approach to refrigerant management varies based on the facility's equipment and regulatory requirements.

Data Centers: These facilities rely on precision cooling and cannot tolerate performance degradation. They often employ systems with strict refrigerant management protocols, including frequent electronic leak detection and pressure testing to ensure uptime.

Grocery Stores: A supermarket with extensive CO2 refrigeration systems may implement continuous monitoring with built-in alarms to detect leaks instantly, protecting valuable inventory and ensuring food safety. As businesses explore commercial HVAC and refrigeration maintenance, they find that integrated systems are key.

Office Buildings: A building transitioning from older refrigerants like R-410A to newer, low-GWP (Global Warming Potential) alternatives must perform a meticulous leak check and repair process before charging the system with the new refrigerant to ensure compliance and system integrity.

Maintaining accurate refrigerant levels is not just about performance; it’s a critical aspect of responsible and cost-effective facility management.

Pro Tip: Always maintain a detailed refrigerant log for each piece of equipment. Document the date of service, pressures and temperatures recorded, the amount of any refrigerant added or recovered, and the results of leak tests. This log is essential for tracking performance and is required for EPA compliance.

7. Drainage System Maintenance

The condensate drainage system is a crucial, yet often overlooked, component of your commercial HVAC unit. As the system cools and dehumidifies the air, it produces a significant amount of water (condensate) that must be safely routed away. This system, which includes drain pans, pipes, and traps, prevents water from overflowing and causing extensive damage to the building, equipment, and inventory. A proactive approach to drainage maintenance is a non-negotiable part of any comprehensive commercial HVAC maintenance checklist.

Why It's a Top Priority

A clogged or malfunctioning condensate drain line can lead to immediate and expensive consequences. Water overflow can saturate ceilings, walls, and floors, leading to structural damage and costly repairs. More insidiously, the standing water in a clogged drain pan creates a perfect environment for the growth of mold, mildew, and bacteria. These contaminants can be circulated throughout the building, severely compromising indoor air quality and posing health risks to occupants.

Practical Implementation and Examples

The maintenance needs of a drainage system vary based on the facility's operational demands and environmental conditions.

Hotels: In a hospitality setting, a water leak can disrupt guest experiences and damage rooms. Many hotels implement automated condensate pump monitoring systems that send alerts to maintenance staff at the first sign of a high-water level, preventing overflows.

Medical Facilities: To uphold strict hygiene standards, medical clinics often install UV germicidal lights directly in the drain pans. This technology constantly sanitizes the pan and coils, preventing microbial growth and supporting infection control protocols.

Schools: Educational facilities typically schedule thorough drain line flushing and cleaning during the summer maintenance period when the buildings have low occupancy, ensuring the systems are clear and ready for the school year.

Pro Tip: Place slow-release biocide tablets in the condensate drain pan at the beginning of the cooling season. These tablets dissolve over time, preventing the buildup of slime, algae, and other organic matter that commonly causes clogs. This simple step can prevent emergency service calls.

8. System Performance Testing and Documentation

Beyond simple visual inspections, system performance testing provides a quantitative, data-driven look into how your commercial HVAC system operates. This process involves measuring key performance indicators (KPIs) like temperature splits, airflow volumes, static pressure, humidity levels, and energy consumption. This data creates a vital performance baseline, allowing facility managers to track trends over time, identify inefficiencies, and diagnose potential problems before they lead to failures. It’s a proactive step in any advanced commercial HVAC maintenance checklist that moves from reactive repairs to strategic asset management.

Why It's a Top Priority

Without performance data, you are essentially flying blind. A system can seem to be running correctly while secretly consuming excessive energy or failing to maintain design specifications for temperature and humidity. Documenting these metrics allows you to spot gradual performance degradation, such as a slow refrigerant leak or a fan motor losing efficiency. This trend analysis is crucial for predictive maintenance, budget forecasting, and ensuring the system meets the environmental needs of the building and its occupants.

Practical Implementation and Examples

The application of performance testing varies significantly based on the facility’s operational goals and regulatory requirements.

Corporate Campuses: These facilities often use Internet of Things (IoT) sensors and building automation systems (BAS) for continuous, real-time performance monitoring, flagging anomalies for immediate investigation.

Government Buildings: To comply with standards like ASHRAE 90.1, government facilities conduct rigorous, scheduled performance tests to verify energy efficiency and document adherence to strict public sector mandates.

Manufacturing Facilities: A plant seeking ISO 50001 certification will meticulously track and document energy consumption and system performance to demonstrate continuous improvement in energy management.

A comprehensive testing and documentation strategy is essential for optimizing system efficiency. For a structured approach, you can explore templates for your preventive maintenance checklist to ensure all critical data points are captured.

Pro Tip: Establish your system's baseline performance measurements immediately after commissioning or a major service. Compare all future readings against this "as-new" data and the manufacturer's original specifications. Use a cloud-based Computerized Maintenance Management System (CMMS) for easy data entry, access, and analysis across your maintenance team.

8-Point Commercial HVAC Maintenance Checklist Comparison

Item | Implementation Complexity | Resource Requirements | Expected Outcomes | Ideal Use Cases | Key Advantages |

|---|---|---|---|---|---|

Air Filter Inspection and Replacement | Moderate - routine manual tasks | Filters, labor, possible monitoring equipment | Improved air quality, energy savings, equipment longevity | Offices, hospitals, manufacturing | Enhances air quality, energy efficiency, prevents damage |

Coil Cleaning and Inspection | High - specialized equipment and chemicals | Chemical cleaners, pressure washers, skilled labor | Restored heat transfer, reduced energy use (10-40%), longer coil life | Restaurants, data centers, retail | Boosts efficiency, prevents early coil failure, improves dehumidification |

Belt and Motor Inspection | Moderate - technical skill needed | Measurement tools, skilled technicians | Prevents failures, improves energy use (2-5%), lowers noise | Manufacturing plants, offices, malls | Avoids breakdowns, extends component lifespan, reduces vibration |

Thermostat and Controls Calibration | High - complex programming and integration | Calibrated instruments, software, trained staff | Precise temperature control, energy savings, remote system monitoring | Corporate HQs, schools, healthcare | Accurate control, energy management, remote troubleshooting |

Ductwork Inspection and Sealing | High - specialized testing and repair tools | Leak detection equipment, sealing materials, labor | Reduced energy loss (20-30%), better air quality, comfort | Office buildings, retail stores, warehouses | Significant energy savings, improved comfort, reduces system workload |

Refrigerant Level and Leak Detection | High - regulatory compliance and technical | Leak detectors, pressure gauges, certified technicians | Optimal cooling, environmental compliance, lower costs | Grocery stores, office buildings, data centers | Maintains efficiency, prevents violations, extends compressor life |

Drainage System Maintenance | Low to Moderate - manual cleaning tasks | Cleaning tools, biocides, UV lights | Prevents water damage, microbial growth, odor control | Hotels, medical facilities, schools | Protects building, controls bacteria, reduces emergency calls |

System Performance Testing and Documentation | High - data analysis and instrumentation | Specialized meters, software, trained personnel | Enables optimization, regulatory compliance, predictive maintenance | Corporate campuses, government buildings, manufacturing | Identifies savings, supports compliance, aids warranty claims |

Partner with Professionals for Peak Performance

Navigating the complexities of commercial HVAC systems requires more than just a passing glance; it demands a structured, proactive approach. This comprehensive commercial hvac maintenance checklist serves as your strategic roadmap, moving you from reactive repairs to a state of predictive, preventative care. We've detailed the essential tasks, from routine air filter replacements and meticulous coil cleaning to critical refrigerant level checks and thorough ductwork inspections. Each step, whether performed weekly, monthly, quarterly, or annually, is a crucial investment in your system's health and your business's operational continuity.

By diligently following this framework, you are not just maintaining equipment; you are actively managing a core business asset. The benefits extend far beyond simple comfort. They translate directly into tangible financial gains through optimized energy efficiency, a significant reduction in costly emergency breakdowns, and the extended operational lifespan of your valuable HVAC units. Furthermore, a well-maintained system guarantees superior indoor air quality, a critical factor for the health and productivity of your employees, tenants, and customers.

From Checklist to Action: The Value of Expertise

While this guide empowers your in-house team with a clear plan, the true mastery of commercial HVAC maintenance lies in the hands of seasoned professionals. The technical nuances of calibrating sophisticated controls, detecting subtle refrigerant leaks, or assessing motor and belt integrity require specialized tools and years of hands-on experience. An expert technician doesn't just follow a checklist; they interpret the data, identify potential issues before they escalate, and ensure every component works in perfect harmony.

Think of this checklist as the blueprint and a professional HVAC partner as the master builder. They bring the blueprint to life with precision and foresight.

Key Takeaway: A detailed commercial hvac maintenance checklist is your first line of defense. Partnering with certified technicians is your guarantee of peak performance, ensuring every task is executed to the highest industry standard for maximum efficiency and system longevity.

Ultimately, protecting your investment and ensuring uninterrupted business operations is the primary goal. Consistent, professional maintenance is the single most effective strategy to achieve this. It transforms your HVAC system from a potential liability into a reliable, efficient, and powerful asset that supports your business's success day in and day out. Don't wait for a system failure to highlight the importance of proactive care; make it a cornerstone of your facility management strategy today.

Ready to ensure your system receives the expert attention it deserves? Partner with Putnam Mechanical LLC to implement a customized commercial hvac maintenance checklist tailored to your specific needs. Visit us at Putnam Mechanical LLC to schedule a consultation and discover how our 75+ years of combined experience can optimize your system for peak performance and reliability.

_edited%20copy.png)