Demystifying the Cost of Commercial HVAC Systems

- Putnam Mechanical

- Aug 30, 2025

- 16 min read

Trying to nail down the cost of a commercial HVAC system can feel a bit abstract. For a standard installation, you're typically looking at a range between $5,000 and $12,500, which covers both the equipment and the labor. But that’s just a starting point. For more complex projects that need a lot of new ductwork or specialized units, it's not uncommon to see the total investment climb past $22,000.

Your Quick Guide to Commercial HVAC System Costs

Budgeting for a new commercial HVAC system is a lot like buying a vehicle for your business. Think about it: a simple cargo van for local deliveries has a completely different price tag and purpose than a custom-fitted, heavy-duty truck built for specialized hauling. The van gets the basic job done, while the truck is a serious investment in specific, high-demand capabilities.

It’s the same with your HVAC. The final price tag is a blend of the equipment itself, the skilled hands required for installation, and the unique demands of your building. Those initial numbers give you a ballpark, but they don’t tell the whole story. To get an accurate quote, you have to look under the hood at factors like your facility's size, the type of system you need, and even where you're located.

To give you a clearer starting point, let's look at what the numbers typically shake out to.

Commercial HVAC System Cost at a Glance

This table breaks down the common expenses you'll see on a quote, giving you a quick reference for what to expect.

Cost Component | Average Price Range | Key Factors |

|---|---|---|

HVAC Unit (Equipment) | $3,000 – $9,000+ | Tonnage (size), brand, energy efficiency (SEER rating), and system type (e.g., rooftop, split-system). |

Labor & Installation | $2,000 – $6,000+ | Project complexity, technician experience, regional labor rates, and time required for installation. |

Ductwork Installation | $1,000 – $2,700+ | The size of the building, the complexity of the layout, and whether it's a new install or a replacement. |

Permits & Misc. | $300 – $1,500+ | Local permit fees, necessary electrical upgrades, or minor structural modifications. |

Remember, these are just averages. A simple swap-out will be on the lower end, while a complex installation in a large or older building will push costs higher.

Breaking Down the Initial Numbers

Industry data shows that the average cost to install a new commercial HVAC system lands around $7,500. This figure usually covers the core equipment and the labor for a pretty straightforward installation.

However, most commercial buildings have needs that go beyond the basics. For instance, if your space requires brand-new ductwork, that alone can add another $1,000 to $2,700 to the project. Want to add advanced features like a high-efficiency HEPA filtration system? That will also bump up the final price. For a deeper dive into these numbers, check out this insider's price guide for heating and cooling systems.

A commercial HVAC system isn't just an expense; it's a critical infrastructure investment. Viewing it through this lens helps you make strategic decisions that balance upfront costs with long-term operational efficiency and occupant comfort.

Core Components of Your Total Cost

The total cost of a commercial HVAC system isn’t just one big number. It’s a combination of several key expenses every business owner should know about. Understanding these moving parts helps you read quotes more effectively and see exactly where your money is going.

Your final invoice will generally break down into these main buckets:

Equipment Costs: This is the price of the physical HVAC unit. It can vary wildly based on its size (tonnage), the brand you choose, and its energy efficiency rating.

Labor and Installation Fees: This often makes up a big chunk of the total. It covers the technicians' time, their expertise, and the specialized tools needed to get the job done right.

Ductwork and Ventilation: Think of this as the "lungs" of your building. This is the cost tied to installing, modifying, or repairing all the necessary ductwork.

Permits and Additional Modifications: This can include things like local permits, any required electrical upgrades, or even small structural changes needed to support the new unit.

When you see the cost broken down this way, you can budget with more confidence and ask contractors the right questions. It’s the best way to make sure there are no surprises down the road.

Decoding the Key Drivers of HVAC Pricing

Trying to understand why one commercial HVAC system costs so much more than another can be confusing. But the final quote you get isn't just a random number; it's a careful calculation based on several major factors that affect performance, lifespan, and your budget. Think of it less like buying a machine and more like commissioning a custom-built solution for your specific building.

A few powerful drivers shape the total cost of a commercial HVAC system. These include the sheer size of your facility, the type of equipment you need, the brand’s reputation, and the system's energy efficiency. Each piece of this puzzle plays a big role in your upfront investment and your long-term operating costs.

Once you break these components down, you stop being a passive price-taker and become an informed buyer. You’ll be able to ask the right questions and make smart decisions that will benefit your business for years.

Building Size and System Capacity

The most basic factor driving the price is the size of the space you need to heat and cool. This goes beyond simple square footage—it's about the building's total volume, layout, number of occupants, and even the heat thrown off by equipment inside. All this data goes into a "load calculation," which tells us the required tonnage, a term for the system's cooling power.

A sprawling retail store with high ceilings and giant display windows will need a much more powerful—and more expensive—unit than a small office building with the same square footage. A bigger, more powerful system simply costs more to build, ship, and install.

Key Takeaway: Getting the system size right is absolutely critical. An undersized unit will run nonstop, struggling to hit the right temperature and burning out way too soon. An oversized unit will switch on and off constantly, failing to properly dehumidify the air and wasting a ton of energy.

Equipment Type and Brand Reputation

The specific type of HVAC system your building needs is another huge piece of the cost puzzle. Different technologies are built for different jobs, and their prices vary a lot.

Rooftop Units (RTUs): These are the all-in-one workhorses you see on top of many commercial buildings. They are fairly straightforward to install, which often makes them a cost-effective choice.

Split Systems: These offer more flexibility for buildings with multiple zones or smaller spaces, but the installation can be more complex since they have separate indoor and outdoor parts.

Variable Refrigerant Flow (VRF) Systems: This is an advanced technology that can heat one area while cooling another. It's perfect for places like hotels or medical offices, but all that complexity comes with a much higher upfront price tag.

Beyond the system type, the brand's reputation and quality also matter. Well-known brands with a track record for reliability and strong warranties will usually cost more. They tend to offer different product tiers, from basic models to premium units packed with advanced features.

The Critical Role of Energy Efficiency

Finally, a system's energy efficiency rating has a direct line to its upfront cost. You’ll see ratings like SEER (Seasonal Energy Efficiency Ratio) or EER (Energy Efficiency Ratio). The higher the number, the more efficient the unit is—and the more it will cost to buy.

This creates a classic trade-off: pay more now for lower energy bills later. A high-SEER unit might cost thousands more at the start, but it can shave a significant amount off your monthly utility bills. Since long-term costs are a huge part of the equation, it's vital to focus on maximizing HVAC energy efficiency.

The right efficiency level for you often comes down to your local climate, energy prices, and how long you plan to own the building. Investing in a modern, efficient system not only cuts down on expenses but also improves your indoor air quality and reliability. To learn more, check out the key benefits of upgrading to a modern commercial AC system and see the difference it can make.

Comparing Costs of Different HVAC System Types

Choosing the right commercial HVAC system feels a lot like picking an engine. You wouldn't put a tiny four-cylinder in a semi-truck, and you wouldn't drop a massive V8 into a compact car. Each is built for a specific job, and the same goes for HVAC systems. The technology you pick directly impacts your upfront cost and how well it performs for years to come.

The final cost of a commercial HVAC system is tied directly to its type. Some systems are designed as straightforward, all-in-one workhorses, while others give you pinpoint control over complex spaces. Getting a handle on these differences is the first step toward making a smart investment.

Packaged Rooftop Units (RTUs): The All-in-One Workhorse

Packaged rooftop units, or RTUs, are the go-to for many single-story commercial buildings like retail stores, warehouses, and standalone restaurants. Think of an RTU as a reliable desktop computer—it has all the key components (compressor, condenser, and evaporator) tucked into one sturdy cabinet that sits on the roof.

This all-in-one design makes installation much simpler and more affordable than other systems. Maintenance is also more direct since a technician can access everything in one spot.

Split Systems: Flexible and Versatile

Just like the name suggests, a split system divides the HVAC components into two main parts: an outdoor unit with the compressor and condenser, and one or more indoor units with the evaporator coils and air handler. This setup is perfect for smaller commercial spaces like offices, small clinics, or multi-level buildings where a single rooftop unit just won't work.

The biggest advantage here is flexibility. You can place indoor units in different zones for better temperature control across various rooms or floors. But that flexibility comes with a more involved installation, since refrigerant lines have to be run between the indoor and outdoor parts, which bumps up labor costs. Making the right call is critical, and our guide on how to choose the right HVAC system for your business can walk you through the details.

Variable Refrigerant Flow (VRF) Systems: Precision and Efficiency

Variable Refrigerant Flow (VRF) systems are the high-tech option in the commercial HVAC world. If an RTU is that reliable desktop PC, a VRF system is like a custom-built server network—highly scalable and designed for specific, complex needs. These systems use a single outdoor unit connected to multiple indoor units, and each one can be controlled on its own.

That means a VRF system can heat one office while cooling another at the same time, making it ideal for buildings with diverse needs like hotels, medical facilities, or multi-tenant office buildings.

VRF systems deliver top-tier energy efficiency and precise zone control, but this advanced technology comes with the highest upfront equipment and installation cost. The investment often pays for itself through major long-term energy savings.

To help you see how these options stack up, here’s a quick comparison of the most common system types.

Comparison of Commercial HVAC System Types and Costs

System Type | Best For | Typical Equipment Cost Range | Primary Advantage |

|---|---|---|---|

Packaged Rooftop Unit (RTU) | Single-story buildings with large, open floor plans (retail, warehouses). | $4,000 - $15,000+ | Cost-effective installation and straightforward maintenance. |

Split System | Smaller or multi-level spaces needing zoned control (offices, clinics). | $5,000 - $20,000+ | Flexible installation and targeted temperature control. |

Variable Refrigerant Flow (VRF) | Buildings with diverse heating/cooling needs (hotels, medical facilities). | $15,000 - $50,000+ | Superior energy efficiency and simultaneous heating and cooling. |

Each system has its place, and choosing the right one means balancing your building's needs with your budget.

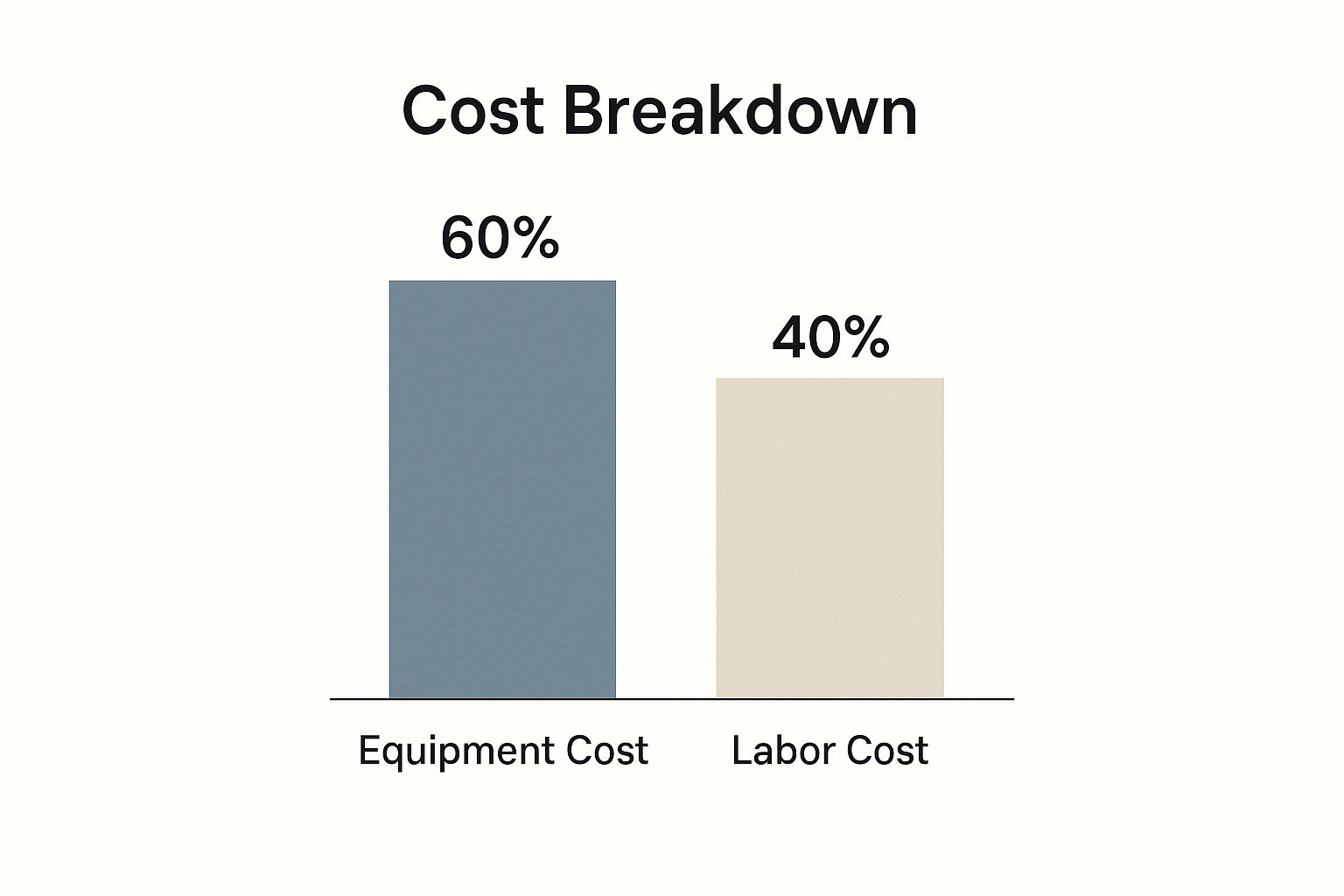

As you can see from the infographic below, equipment is the biggest piece of the pie, but labor costs are a significant part of the total investment.

The price of the equipment itself also varies widely. For example, furnaces can run from $2,000 to $8,000, while boilers can reach up to $16,000. Heat pumps have the broadest price range, from around $2,500 to $39,000, especially for advanced geothermal models. Ultimately, matching the system type to your building’s unique demands is the key to balancing cost and performance.

Uncovering the Hidden Costs of Installation

The price tag on the HVAC unit itself is just the first piece of the puzzle. When you're calculating the total cost of a commercial HVAC system, it’s easy to focus on the hardware, but the reality is that installation introduces a whole new set of expenses that can seriously inflate your budget.

Believe it or not, the labor, ductwork, and other site-specific needs often account for nearly half of the final project cost. If you ignore these factors, you’re setting yourself up for unexpected overruns and a skewed view of your real financial commitment.

To create an accurate budget, you have to look beyond the shiny new machine and understand everything it takes to get that system up and running safely and efficiently.

The Major Role of Labor Costs

Skilled labor is one of the biggest—and most variable—expenses you’ll face. Unlike a simple appliance that just plugs into the wall, installing a commercial system is a complex job. It demands certified technicians who bring specialized knowledge and tools to the table.

Several key factors will influence your final labor bill:

Project Complexity: A straightforward rooftop unit swap will cost far less in labor than a complex VRF system that requires extensive refrigerant line work and detailed calibration.

Building Accessibility: Is your building tough to get to? If technicians need a crane to lift units onto a high roof or have to navigate tight, cramped spaces, labor hours and costs are going to climb.

Regional Wage Standards: A technician’s hourly rate can vary dramatically from one city to another, and that difference will show up on your invoice.

Because of this complexity, labor can easily eat up 40% to 50% of your total installation budget.

Ductwork: The Building’s Respiratory System

Think of your building's ductwork as its respiratory system. This network of channels is responsible for delivering clean, conditioned air to every corner of your space and pulling out the stale air. If this system is poorly designed, damaged, or the wrong size, even the best HVAC unit in the world won’t perform well.

The condition of your existing ductwork plays a huge role in the final cost.

Your ductwork must be perfectly matched to your new HVAC unit's capacity. A mismatch is a leading cause of inefficiency, poor air quality, and premature equipment failure. That makes a professional ductwork assessment a non-negotiable step in the quoting process.

Depending on what the pros find, you could be looking at one of three scenarios:

New Ductwork Installation: This is the most expensive route, usually for new construction or buildings where the old ducts are unsalvageable. The upside? You get a perfectly designed system from scratch.

Ductwork Retrofitting: A more common and affordable option, this involves modifying or adding to existing ducts to accommodate the new system’s airflow requirements.

Simple Repairs and Sealing: If your ducts are in good shape, they might just need minor patching or sealing to prevent air leaks. This is by far the most cost-effective solution.

Other Potential Installation Expenses

Beyond labor and ductwork, a few other "hidden" costs can pop up on your final invoice. Knowing about them ahead of time helps you build a complete and realistic budget.

Permits and Inspections: Most cities and counties require permits for commercial HVAC work to ensure it meets safety and building codes. These fees can range from a few hundred to over a thousand dollars.

Electrical Upgrades: A powerful new HVAC system might need more juice than your current electrical panel can provide. Upgrading the panel is another potential expense to plan for.

Old System Disposal: Your old HVAC unit can't just be tossed in a dumpster. It needs to be safely decommissioned and disposed of, which involves a fee for labor and the proper removal of environmentally sensitive refrigerants.

Long-Term Maintenance: Smart business owners also factor in ongoing upkeep from day one. To learn more, our guide on how regular maintenance prevents costly equipment breakdowns is a must-read.

For major commercial projects, like a full system overhaul or a new build, you might want to look into specialized financing. Options like hard money loans for commercial real estate can be a practical way to manage these extensive upfront costs.

How Market Trends Are Shaping HVAC Prices

Ever wonder why the quote for a new system seems a lot higher than you remember? The cost of a commercial HVAC system doesn't exist in a bubble—it’s directly tied to powerful global economic forces. Understanding what’s happening behind the scenes helps you anticipate price shifts and make a smarter, more strategic purchase.

Think of it like the price of gas. Factors happening miles away—like global crude oil production or international politics—are what really set the price you pay at the pump. It's the same with HVAC equipment. A complex web of supply chain snags, inflation, and the rising cost of raw materials all shape the final price tag.

When core metals like copper, steel, and aluminum get more expensive on the global market, manufacturers have to pay more to build each unit. That increase inevitably trickles down to you, showing up as a higher number on your quote.

The Impact of Tariffs and Regulations

It’s not just raw materials, either. Government policies also play a huge part. New tariffs and regulations on imported HVAC components can tack a noticeable percentage onto the equipment cost. Many of the most critical parts—compressors, motors, and complex circuit boards—are made overseas.

When a new tariff hits these components, it acts like a tax that gets added at every step of the supply chain.

A new tariff on imported compressors might not sound like a big deal on its own. But when you combine it with rising steel prices and shipping delays, it creates a domino effect that can seriously inflate the cost of a complete rooftop unit.

This is a major reason why pricing can feel so unpredictable right now. The commercial HVAC market is seeing a clear price increase driven by these exact economic and regulatory pressures. New tariffs on imported parts have added 8% to 15% to equipment prices, and overall equipment costs have already jumped by roughly 12% in the past year alone. You can discover more insights about rising HVAC prices on yarbroughandsons.com for a deeper analysis.

Navigating an Unpredictable Market

So, what does all this mean for you as a business owner or property manager? It means that waiting to replace an old, inefficient system might end up costing you more, not less. In an inflationary market with ongoing supply chain issues, prices are more likely to keep climbing.

Planning ahead has never been more important. This includes:

Budgeting Proactively: Start setting aside funds for a replacement or major repair now, and assume the cost will be higher than it was a few years back.

Prioritizing Maintenance: Keeping your current system in peak condition is the best way to delay a full replacement. For a closer look at this strategy, check out our article on why property managers should prioritize routine HVAC maintenance.

Acting Decisively: When it's finally time to upgrade, getting multiple quotes and locking in a price can protect you from future increases.

By understanding the outside forces shaping the market, you can navigate the process with confidence and make a timely, cost-effective decision for your property.

A Practical Framework for Getting Accurate Quotes

Navigating the quoting process for a big investment like a new HVAC system can feel like a maze. But if you have a clear game plan, you can move forward with confidence and land a competitive, reliable quote. This framework will help you sidestep the common pitfalls and make sure you get a fair price for a quality installation.

First things first: you absolutely must insist on a professional load calculation. Think of it like getting a survey done before you build a house—it's the non-negotiable foundation for the whole project. This detailed analysis, often called a Manual J calculation, looks at your building’s size, insulation, window types, and even how many people are inside to figure out the exact heating and cooling power you need.

Without this calculation, a contractor is just guessing. That can leave you with an undersized unit that can’t keep up on hot days or an oversized one that constantly cycles on and off, wasting a ton of energy.

Secure and Compare Itemized Quotes

Once that load calculation is in hand, the next move is to get at least three itemized quotes from reputable, licensed commercial contractors. This is the only real way to get a feel for the market rate and the true cost of a commercial hvac system in your area.

But be careful—not all quotes are created equal. A vague, one-page estimate is a huge red flag. A professional quote should be a detailed document that breaks down every single part of the job, giving you a transparent look at where your money is going.

A truly comprehensive quote empowers you to make an informed decision. It moves the conversation from "How much will it cost?" to "What exactly am I getting for my investment?" This level of detail protects you from hidden fees and ensures you are comparing apples to apples.

Anatomy of a High-Quality Quote

To make sure you’re getting all the information you need, use this checklist as you review each proposal. Every solid quote should include:

Detailed Equipment Breakdown: This should list the specific make, model, and serial numbers for all major components, along with their efficiency ratings (SEER/EER).

Itemized Labor Costs: The quote needs to clearly separate the cost of labor from the equipment. It should outline the scope of work and give you an estimate of the hours involved.

Warranty Information: Look for specifics on both the manufacturer’s parts warranty and the contractor’s labor warranty.

Permit and Inspection Fees: The contractor should be handling all the necessary permits, and those costs should be listed clearly.

Project Timeline: A clear start date and an estimated completion date help set expectations and let you manage your business operations around the installation.

Beyond the initial quotes, you’ll want to keep a close eye on expenses as the project gets underway. You can learn more about how to get your day back by efficiently tracking job and project costs. Finally, always vet your potential contractors. Verify their licenses, check for valid insurance, and ask for a few recent client references. This due diligence is your best defense against shoddy work and future headaches.

Common Questions About Commercial HVAC Costs

Making a big investment like a new commercial HVAC system is bound to bring up a few questions. That's perfectly normal. Getting clear answers helps you move forward with confidence, ensuring you make a smart, cost-effective decision that serves your business for years.

Here are some straightforward answers to the questions we hear most often from business owners.

How Can I Reduce My Total Cost?

While the initial price tag can look intimidating, there are several savvy ways to bring down the overall investment. Timing is one. If you can schedule your purchase during the off-season (think spring or fall), you can sometimes find better pricing from contractors who aren't in their busiest season.

It also pays to look for manufacturer rebates or local utility incentives, which often reward businesses for installing high-efficiency units. And speaking of efficiency, choosing the right tier is key. The most expensive, highest-SEER unit isn't always the best fit. A solid mid-tier system might offer the perfect balance of upfront cost and long-term savings for our Florida climate.

What Makes Commercial HVAC More Expensive?

The price jump from residential to commercial really boils down to three things: durability, complexity, and sheer scale. Commercial units are built like tanks, with heavy-duty components designed to run almost nonstop and survive the harsh conditions on a commercial rooftop. They're also significantly larger and more powerful.

A commercial system is an intricate network built to manage complex ventilation needs, multiple temperature zones, and massive volumes of air—a job that’s far beyond what a home A/C unit is designed for. This requires specialized equipment and installation expertise, which naturally costs more.

How Long Should a Commercial System Last?

With proper care, a well-maintained commercial HVAC system will typically last between 15 and 20 years. But that lifespan isn't a guarantee; it hinges almost entirely on proactive maintenance. If you neglect routine care, you could see a unit fail in as little as ten years, which is a costly and premature end.

Regular maintenance is the single most important thing you can do to maximize your investment. It stops major breakdowns before they happen, keeps the system running efficiently, and helps it reach its full operational life. To get a detailed look at what you could be saving, check out your guide to a commercial HVAC energy audit and see where improvements can be made.

Is a High-Efficiency Unit Worth the Price?

In almost every case, yes. A high-efficiency unit pays for itself over time, delivering a strong return on your investment. While the upfront cost is higher, the long-term energy savings are substantial. You could easily shave 20-40% off your monthly cooling and heating bills.

Not sure if it’s worth it for your specific business? You can calculate the payback period yourself. Just divide the extra cost of the high-efficiency model by your estimated annual energy savings. That number tells you exactly how many years it will take for the unit to pay for itself through lower utility bills.

At Putnam Mechanical LLC, we believe in transparent, upfront pricing to help you make informed decisions for your business. Contact us today for a detailed quote and find a reliable HVAC partner you can trust.

_edited%20copy.png)