Your Preventive Maintenance Schedule Template Guide

- Aug 23, 2025

- 13 min read

At its core, a preventive maintenance schedule template is just a structured document. It’s your game plan for organizing, tracking, and actually doing the regular upkeep on your equipment. Using one ensures your commercial HVAC and refrigeration systems get serviced proactively, stopping failures before they ever have a chance to happen.

Why Proactive Maintenance Is a Game Changer

Before we get into building templates and checklists, let's talk about the mindset shift from reactive to proactive maintenance. It’s a big one. For any business that depends on climate control or cold storage—restaurants, grocery stores, you name it—a "run-to-failure" approach is a high-stakes gamble.

An unexpected equipment breakdown isn’t just an inconvenience; it can be a financial disaster.

Picture a walk-in freezer failing during a Florida heatwave. The immediate fallout includes emergency repair fees, tons of lost product, and a complete halt to business. A proactive strategy, guided by a solid plan, completely flips this scenario. It moves you from a state of constant fire-fighting to one of control and predictability.

Reactive vs Preventive Maintenance Impact

Let's break down the real-world impact of these two approaches. The difference isn't just about fixing things before they break; it's about fundamentally changing how your business operates and manages risk.

Aspect | Reactive Maintenance (Run-to-Failure) | Preventive Maintenance (Scheduled) |

|---|---|---|

Cost | High, unpredictable emergency repair fees, overtime labor, and rush shipping for parts. | Low, predictable costs budgeted in advance. |

Downtime | Frequent and unplanned, leading to significant business interruption and lost revenue. | Minimal and scheduled during off-hours, preventing operational disruption. |

Asset Lifespan | Significantly shortened due to neglect and catastrophic failures. | Extended by 20-40% through regular care and early issue detection. |

Budgeting | Nearly impossible. Every failure is a financial surprise. | Simple and stable. Maintenance costs are a known operational expense. |

Safety | Increased risk of safety incidents from sudden equipment failures. | Reduced risk by identifying and correcting potential hazards early. |

The table makes it clear: waiting for a breakdown is a losing strategy. A scheduled, preventive approach is an investment in stability and long-term savings.

The Cost of Doing Nothing

The hard truth is that waiting for something to break is almost always more expensive. Reactive maintenance comes with premium charges for emergency service, overnight parts shipping, and the painful cost of downtime. It's a stressful, expensive cycle that many businesses get trapped in.

Industry statistics paint a clear picture. A surprising 21% of facilities still rely on a run-to-failure approach, even though nearly 69% of plants deal with unplanned outages every single month because of it. Moving to a scheduled plan is the only proven way to cut down on these costly surprises.

A preventive maintenance plan isn’t an expense; it’s an investment in operational stability. The goal is to spend a little on scheduled upkeep to avoid spending a lot on emergency fixes.

Defining Your Maintenance Strategy

Getting the terminology right helps build a stronger case for a structured approach. Let’s quickly clarify two key concepts you'll run into:

Preventive Maintenance (PM): This is the foundation of your schedule. PM involves routine inspections, cleaning, and parts replacements at set intervals to lower the odds of failure. Think of it like a scheduled oil change for your car—simple, but essential.

Predictive Maintenance (PdM): This is a more advanced strategy that uses data and sensor tech to predict when a part might fail. It allows for even more precise fixes right before something breaks.

For most businesses, a solid PM plan is the perfect starting point. It gives you the framework to stop preventable issues and offers real-world insights into how regular maintenance prevents costly equipment breakdowns. This guide is all about building that foundational PM schedule—the cornerstone of a reliable and efficient operation.

Gathering Your Essential Equipment Data

Any preventive maintenance plan is only as good as the information it’s built on. Before you can even think about scheduling tasks, you have to create a detailed inventory of every single piece of HVAC and refrigeration equipment you’re responsible for. This is the foundation of your entire maintenance strategy, so it really pays to be thorough.

Think of it like building a detailed dossier for each asset. Just writing down "Rooftop Unit 3" on a spreadsheet isn't going to cut it. You need to dig much deeper to build a profile that will inform every service decision you make down the road.

This part of the process can feel a bit tedious, I know. But it's non-negotiable. Skipping this step is like trying to drive across the country without a map—you'll get lost, waste a ton of time, and probably run into some expensive problems.

Locating Your Asset Information

For most newer equipment, finding this info is pretty straightforward. Manufacturers usually put a data plate or sticker right on an exterior panel. This little metal plate is a goldmine of information and has nearly everything you need to get your inventory started.

But for older systems, that plate might be worn down, painted over, or missing altogether. When that happens, you’ll have to do a little detective work. Start by digging through old purchase orders, service invoices from previous contractors, or the original building blueprints. Sometimes, a quick call to the manufacturer with even a partial model number can help you fill in the blanks.

The Essential Data Points to Collect

Your goal here is to build a master list, probably in a spreadsheet. For every piece of equipment—from the main chiller plant down to that small ice machine in the breakroom—you need to document a few critical details.

Here’s what I recommend capturing for each asset:

Asset Name and ID: Give it a clear, unique name you'll recognize (e.g., "RTU-01 - East Roof" or "Walk-In-Freezer-Kitchen").

Location: Be specific about where it is (e.g., "Roof, Sector B" or "Basement Mech Room").

Manufacturer and Model Number: This is crucial for ordering parts and pulling up service manuals.

Serial Number: You'll need this unique identifier for warranty claims and looking up specific parts.

Installation Date: This helps you track the asset's age and start planning for its eventual replacement.

Warranty Information: Make a note of the expiration dates for parts and labor. This simple step can save you thousands on a covered repair.

Prioritizing your equipment is just as important as listing it. A primary walk-in freezer at a restaurant demands a much more aggressive maintenance schedule than a small AC unit in a back office.

Prioritizing Your Assets

Once you’ve got your master list, the next step is to rank each piece of equipment by how critical it is to the business. Let's be honest, not all assets are created equal. A simple tier system is a great way to define their importance.

For example, a Tier 1 asset might be the main air handler for a server room—if that unit goes down, the entire business is at risk. A Tier 2 asset could be a secondary walk-in cooler, where a failure is a big problem but not a complete catastrophe. And a Tier 3 asset might be something less critical, like an exhaust fan in a storage closet.

This ranking will directly influence how often you schedule tasks in your maintenance plan. By understanding which assets are most vital, you can make sure your time and resources are focused where they matter most, protecting the business from the most damaging failures. This data is what transforms a generic checklist into a powerful, customized maintenance plan that actually works.

Building Your Custom Maintenance Template

Now that you have a detailed inventory of your equipment, it's time to put that information to work. This is where we move from a simple list of assets to a real, actionable maintenance plan. You're going to build the core of your preventive maintenance schedule template—a document that spells out exactly who does what, and when.

Forget about finding a perfect, one-size-fits-all template online. A truly effective schedule is something you construct yourself, built to fit the specific needs of your facility and equipment. Think of it less as a checklist and more as a dynamic tool that organizes your entire maintenance workflow, connecting your equipment to the manufacturer's recommendations and your team's responsibilities.

Defining Key Template Components

So, what goes into a good maintenance template? Let's break down the essential columns that bring clarity and accountability to every task.

Asset Details: Start with the basics. List the specific equipment name and its unique ID from your inventory (e.g., "RTU-01 - East Roof").

Task Checklist: Be crystal clear about the work. "Check filter" is too vague. "Inspect and replace MERV 8 filter" leaves no room for guesswork.

Frequency: This is the rhythm of your plan. Assign a cadence for each task—Daily, Weekly, Monthly, Quarterly, or Annually.

Assigned Technician: Who's on the hook? Note whether it's an in-house team member or your trusted service contractor.

Completion Status: You need a simple way to track progress. A checkbox or a field to mark when the task is done, along with the date, is perfect.

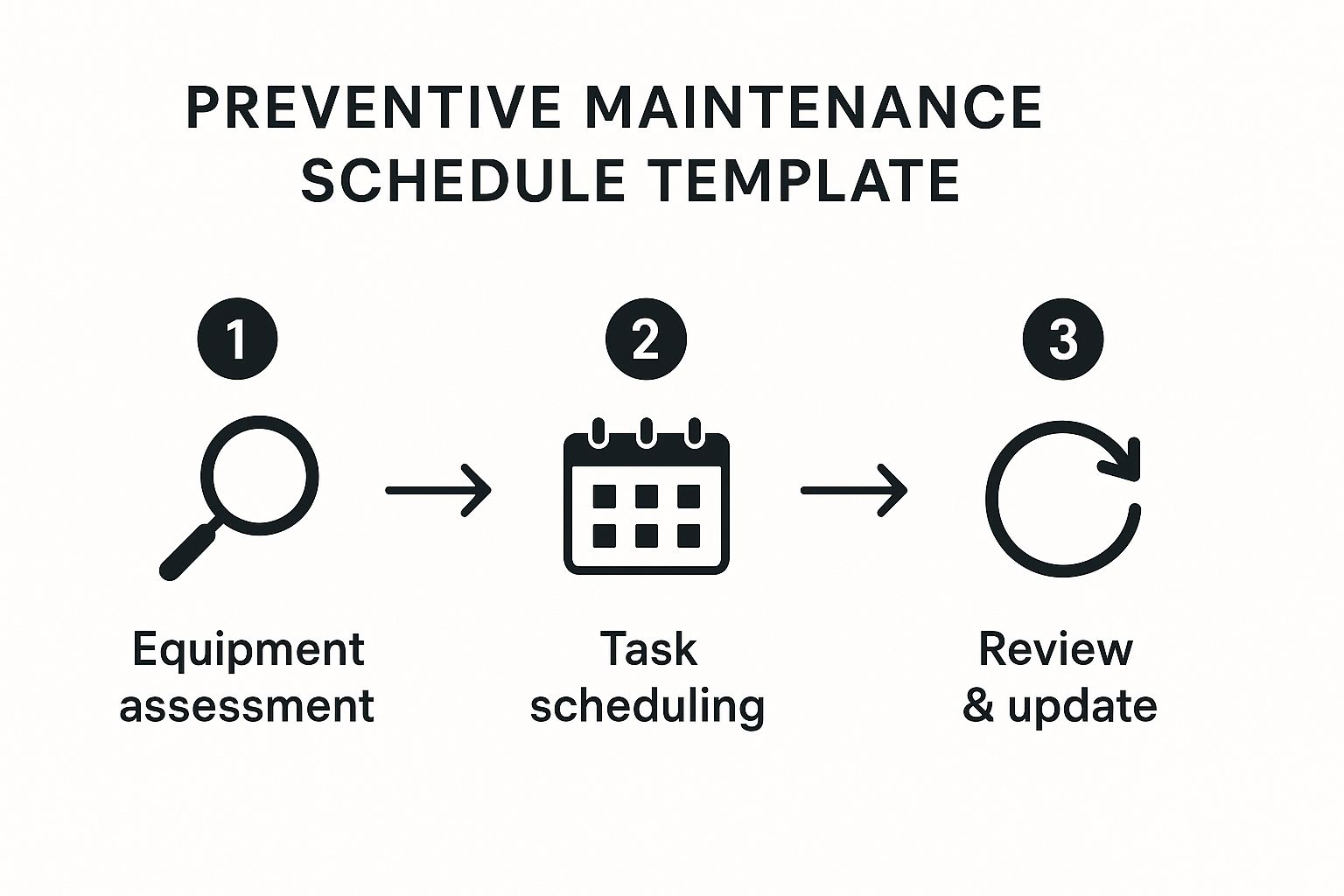

This simple structure helps you see the entire process at a glance, from the equipment itself to scheduling and review.

This flow isn't just a one-time setup; it’s a continuous loop that keeps getting smarter and more efficient.

Real World Example: A Rooftop HVAC Unit

Let's make this tangible with a common commercial asset: a rooftop HVAC unit (RTU) sitting on top of a retail store. The goal here is to create targeted checklists for different timeframes so you're not over-servicing the unit or, worse, neglecting it.

A quick weekly check for this RTU would be mostly visual and take just a few minutes:

Clear away any leaves, branches, or trash from around the unit.

Do a quick visual scan for any obvious damage to the casing.

Listen for any strange sounds, like grinding or intense vibration.

The quarterly inspection, on the other hand, is much more hands-on and requires some technical skill:

Inspect and tighten all electrical connections.

Clean the evaporator and condenser coils.

Check refrigerant levels and pressures to ensure they're within spec.

Lubricate motors and bearings according to the manufacturer's guide.

The real power of a custom preventive maintenance schedule comes from aligning these specific, detailed tasks with a logical frequency. It’s a simple concept, but it drastically reduces the chances of an unexpected breakdown.

The data backs this up, too. One major study found that companies prioritizing preventive maintenance experienced 52.7% less unplanned downtime and 78.5% fewer defects compared to those stuck in a reactive "fix it when it breaks" cycle.

Customizing Your Template

While a basic spreadsheet is a great place to start, don't forget your most important resource: the manufacturer's service manual for each piece of equipment. These manuals are the gold standard for recommended tasks and frequencies. They often include detailed checklists you can lift directly and plug into your template.

For a closer look at what a finished checklist can look like, our guide on your preventive maintenance checklist template offers concrete examples you can adapt. The key is to take these foundational ideas and mold them to fit your building’s unique environment and equipment. When you build your template with care, you’re creating a powerful asset that protects your investments and keeps your operations running smoothly.

Putting Your Maintenance Plan Into Action

A perfectly designed preventive maintenance schedule is a great start, but it only delivers real value when you put it into motion. The transition from a plan on paper to real-world execution is where most maintenance strategies either succeed or fail. It all comes down to clear communication, defined responsibilities, and using the right tools to keep everything on track.

The first move is assigning the work. Every single task on your schedule needs a clear owner, whether that's an in-house tech or a trusted external contractor like us. Vague assignments lead to missed tasks, so get specific. Instead of just "maintenance team," assign tasks to the "Lead Technician" or your dedicated HVAC service provider.

This initial rollout is also the perfect time for a quick training session. Walk your team through the new schedule and explain the "why" behind each task. Consistent execution is everything, and making sure everyone understands their role from day one prevents confusion and guarantees maintenance is done to the same high standard every time.

Creating a Feedback Loop

Your technicians are your eyes and ears on the ground. A crucial part of making your plan work is creating a simple but effective way for them to report anything unusual they find during a routine check.

A slightly loose belt or a faint, odd noise might not seem like a big deal, but it could be the first warning sign of a much bigger problem.

Establish a clear protocol for reporting these observations. It could be as simple as adding a "Notes" section to their checklist or setting up a dedicated communication channel. This feedback is invaluable for a couple of reasons:

It allows for immediate action: A small issue can be addressed before it escalates into a full-blown, costly breakdown.

It helps refine your schedule: If technicians keep finding the same minor issue on a specific unit, you might need to adjust the maintenance frequency for that piece of equipment.

Think of your initial maintenance schedule as a living document. The feedback you get from the field is what allows you to fine-tune your plan, making it smarter and more effective over time.

This continuous improvement cycle transforms your static template into a dynamic, responsive tool that truly protects your equipment.

Using Simple Digital Tools for Tracking

Managing your schedule doesn't have to be complicated. While complex Computerized Maintenance Management Systems (CMMS) are powerful, many businesses can get started with much simpler tools they already use every day.

A shared digital calendar, for example, is a fantastic way to automate reminders for your team. You can create recurring events for monthly, quarterly, and annual tasks, making sure nothing falls through the cracks. This also creates a permanent, searchable digital record of all completed maintenance, which is essential for tracking equipment history.

As property managers know, understanding why to prioritize routine HVAC maintenance is closely tied to having a reliable record of service.

By assigning tasks clearly, training your team, establishing a feedback loop, and using simple digital tools, you can successfully launch your maintenance plan. This practical approach turns your carefully crafted template into a powerful engine for operational reliability and long-term savings.

Evolving Your PM Schedule for Peak Efficiency

A preventive maintenance schedule shouldn't be a "set it and forget it" document. The real magic happens when you treat it as a dynamic tool—one that adapts to the real-world performance of your HVAC and refrigeration equipment. It needs to be a living system that gets smarter over time, driven by what you see on the ground.

Start by digging into your maintenance logs. Are you noticing any patterns? Maybe one specific air handler constantly needs its drain line cleared, or a particular walk-in cooler seems to burn through coolant faster than the others. These recurring issues are red flags.

Trends like these often mean a unit needs more frequent check-ups than you originally planned. In some cases, it's a clear sign that the equipment is nearing the end of its life and needs to be budgeted for replacement. Ignoring these signals is just asking for an emergency breakdown down the line. For any business that relies on refrigeration, understanding how regular refrigeration maintenance can prevent major food loss really drives home why this kind of vigilance is so critical.

Moving from Preventive to Predictive

Once you've got a solid preventive maintenance routine dialed in, the next level is exploring predictive maintenance (PdM). This approach takes your strategy from routine to incredibly precise. Instead of servicing equipment based on a fixed calendar, PdM uses real-time data to anticipate failures before they happen.

How does it work? By installing sensors that monitor key performance indicators, such as:

Vibration analysis on motors and compressors

Thermal imaging to spot overheating electrical components

Oil analysis to check for internal wear and contamination

Refrigerant pressure and temperature monitoring

By collecting and analyzing this data, you can move from, "We should probably check this in three months," to, "This specific bearing is showing early signs of wear and will likely fail in the next 30 days."

This data-first approach lets you plan repairs with surgical accuracy. You can order parts well in advance and schedule downtime for the most convenient moment, not in the middle of a dinner rush. It helps eliminate unnecessary service calls and drastically cuts the risk of a catastrophic, business-halting failure.

The growth in this field is incredible. The global predictive maintenance market was valued at $7.85 billion in 2022 and is projected to skyrocket to $60.13 billion by 2030, all thanks to new AI and machine learning tools. The goal is to transform your preventive maintenance template from a simple checklist into an intelligent system that optimizes your entire operation, saving you money and keeping your doors open.

Common Questions About Preventive Maintenance

Even with the best template in hand, you're bound to have questions when you start putting a new maintenance strategy into practice. I've seen it time and time again. Getting ahead of these common sticking points can be the difference between a schedule that actually works and one that just collects dust.

Let's walk through some of the most frequent questions I hear from facility managers and business owners.

One of the biggest hurdles is often getting your own team on board. If your staff is used to a “run-it-’til-it-breaks” approach, bringing in structured checklists can feel like just another chore. The trick is to frame it as an investment in making their jobs easier, not harder.

Explain how a few minutes spent on a weekly check can prevent hours of chaos and stressful emergency calls down the line. When the kitchen crew understands that checking a simple gasket seal today prevents a cooler from dying on a busy Saturday night, they stop being task-doers and become partners in the process.

How Often Should I Review My Schedule?

Think of your preventive maintenance schedule as a living document, not something you set in stone and forget. It needs to adapt as you learn more about your equipment's quirks and needs.

A great place to start is a formal review every six months.

This is your chance to pull out the maintenance logs and see what they're telling you. Ask yourself a few simple but powerful questions:

Are we seeing the same issue pop up with a specific unit?

Have certain tasks been consistently missed or pushed back? Why?

Did we install any new equipment that needs to be added to the rotation?

Is that one old freezer costing us more in frequent repairs than it's worth?

The answers will help you fine-tune your schedule. You might adjust the frequency of some tasks or add new checks based on the real-world performance of your equipment. This is how you keep the plan sharp and effective.

DIY vs. Calling in the Pros

Another big question is what your in-house team can handle versus what needs a certified technician. It’s a great question, and getting the balance right is key. A good rule of thumb is to let your team manage the frequent, non-technical jobs.

Your staff can absolutely handle daily or weekly visual inspections, swapping out air filters, and basic cleaning. But anything involving electrical components, refrigerant, or complex mechanical parts should always be left to a certified professional.

This approach keeps your team involved and gives them ownership without creating safety risks or causing damage that leads to even costlier repairs. If you want a better sense of what goes into those more technical jobs, our guide to common appliance parts and service offers some valuable perspective. Striking this balance ensures your equipment gets the expert attention it needs while empowering your team to be the first line of defense.

At Putnam Mechanical LLC, we build preventive maintenance plans that protect businesses from the headache and cost of unexpected downtime. If you're ready to shift from reactive fixes to a proactive strategy, contact us today for a free estimate.

_edited%20copy.png)