Installing a High Efficiency Furnace: Your Expert Guide

- Putnam Mechanical

- Sep 13, 2025

- 15 min read

Thinking about replacing your commercial furnace? Don't just think of it as a replacement—see it as a strategic investment in your property's future. Upgrading to a high-efficiency unit is a smart business move that delivers a powerful return through lower energy bills, better comfort for your tenants or employees, and a reduced carbon footprint that aligns with modern expectations.

The Business Case for a High Efficiency Furnace

When you're looking at a new furnace, the first thing on your mind is probably the bottom line. That's fair. The operational savings from a high-efficiency model are substantial, and they start from day one. But the real value goes far beyond just cutting costs.

This upgrade impacts everything from tenant satisfaction and property value to your company's public image. It's not just about swapping an old box for a new one. Modern high-efficiency furnaces are packed with smart technology designed to perform better and use energy smarter. Understanding what's under the hood makes it clear why this is such a solid long-term investment.

Unpacking the Technology and Benefits

The real magic of these systems is in their Annual Fuel Utilization Efficiency (AFUE) rating. Your old furnace might be chugging along at 70-80% AFUE, meaning a good chunk of your fuel money is going right up the chimney. High-efficiency models, on the other hand, can hit up to 99% AFUE.

That means for every dollar you spend on fuel, 99 cents goes directly into heating your building. This massive leap in efficiency comes from a few key pieces of tech:

Secondary Heat Exchanger: This is the real game-changer. It grabs heat from the exhaust gases that older furnaces waste, squeezing every last bit of energy out of your fuel.

Modulating Gas Valves: Instead of blasting "on" or shutting "off," these valves adjust the flame in tiny increments to perfectly match the building's heating needs. This smooth operation prevents energy-wasting cycles and keeps temperatures incredibly consistent.

Variable-Speed Blowers: These smart motors adjust their speed based on demand, using far less electricity than old single-speed blowers. The result is quieter operation and more even airflow throughout your space.

A high-efficiency furnace isn't just another piece of HVAC equipment; it's a strategic asset. By slashing energy waste and boosting comfort, it directly contributes to a more profitable and sustainable building. Plus, a comfortable environment makes your property far more attractive in a competitive market.

To give you a clearer picture, here’s a quick breakdown of how these units stack up.

High Efficiency vs Standard Furnace A Quick Comparison

This table offers a side-by-side look at the key differences in performance and financial impact between standard and high-efficiency models. It really highlights where the value is.

Feature | Standard Efficiency Furnace (80% AFUE) | High Efficiency Furnace (95%+ AFUE) |

|---|---|---|

Energy Efficiency | Wastes 20% of fuel as exhaust | Wastes less than 5% of fuel |

Monthly Bills | Higher operational costs | Significant monthly energy savings |

Technology | Single-stage heating, single-speed blower | Modulating heat, variable-speed blower |

Comfort | Prone to temperature swings, hot/cold spots | Consistent, even heating throughout |

Venting | Requires a traditional chimney | Vents through PVC pipe, more flexible |

Upfront Cost | Lower initial investment | Higher initial investment |

Long-Term ROI | Lower return over the unit's lifespan | Higher ROI through energy savings |

As you can see, while the initial cost is higher, the long-term savings and performance benefits make a high-efficiency unit the smarter financial choice over time.

Beyond the Balance Sheet

The numbers are compelling, but the operational and environmental benefits are just as crucial. Better temperature control gets rid of those annoying hot and cold spots—a frequent complaint in commercial buildings—which leads to happier, more productive people. You can also explore other ways to https://www.pmechanicalfl.com/post/boost-commercial-building-energy-efficiency-today that work hand-in-hand with your new furnace.

A lower carbon footprint also sends a powerful message. Aligning with sustainable building practices and energy efficiency standards shows a commitment to the environment that can boost your brand's reputation and attract eco-conscious clients and tenants.

The entire industry is moving in this direction. The global furnace market is projected to jump from USD 18.1 billion in 2025 to USD 30.3 billion by 2035, largely because of rising energy standards and the need to replace outdated systems. This trend shows that investing in efficiency isn't just a good idea—it's the future.

Pre-Installation Planning and Assessment

A high-efficiency furnace installation is won or lost long before anyone picks up a tool. This planning phase is everything. Think of it as your project's blueprint—it’s what prevents those costly surprises down the line and makes sure your new system performs at its peak from day one.

Jumping straight into the installation without a detailed assessment is one of the most common—and expensive—mistakes we see. Every commercial building has its own quirks, from the ductwork and ventilation to the electrical setup. A thorough site evaluation isn't just a good idea; it's a non-negotiable first step.

This process is all about getting a complete picture of your building's existing systems. We’re looking for potential roadblocks and, just as importantly, opportunities to make things even better.

Conducting a Thorough Site Assessment

Your initial walkthrough needs to be meticulous. Start with the heart of any HVAC system: the ductwork. Are there obvious signs of damage, like crushed sections, gaps, or joints that have come apart? Leaky ducts will kill the efficiency of even the best furnace, dumping all that precious heated air into ceilings and crawlspaces. You can learn more about how damaged ductwork impacts your HVAC system’s efficiency in our detailed guide.

Next up, get your eyes on the ventilation and electrical systems. High-efficiency furnaces have very specific venting needs, usually involving PVC pipes for both intake and exhaust. You’ll need to map out a clear path for these pipes to run from the furnace to an exterior wall or the roof, making sure you follow the manufacturer's specs on length and pitch. Your electrical panel also needs to be able to handle the new unit's load without issue.

Here are the key things to zero in on during your assessment:

Existing Duct Condition: Check for leaks, proper sizing, and good insulation. Undersized or leaky ducts will choke the airflow and make your new furnace underperform.

Venting Pathways: Find a direct route for the new PVC intake and exhaust pipes. Too many bends will restrict airflow and cause problems.

Condensate Drain Access: These high-efficiency units produce condensation, and that water has to go somewhere. Make sure there’s a floor drain nearby or a spot to install a condensate pump.

Electrical System Compatibility: Verify the circuit breakers and wiring can safely support the new furnace's electrical demands.

Gas Line Adequacy: If you're installing a natural gas furnace, the gas line must be the right size and in good shape to fuel the unit safely. A critical part of this is ensuring you install natural gas lines safely and correctly according to code.

The Importance of Accurate Load Calculations

One of the biggest mistakes you can make in a furnace installation is getting the size wrong. A unit that's too big or too small will lead to inefficiency, extra wear and tear, and uncomfortable temperature swings. The industry standard for getting this right is a Manual J load calculation.

This isn't just a guess based on square footage. A proper Manual J calculation is a deep dive that looks at dozens of factors specific to your building.

A proper load calculation is the foundation of an efficient HVAC system. It ensures you're investing in a furnace that's perfectly matched to your building's unique heating needs, preventing the energy waste and premature failure associated with incorrectly sized equipment.

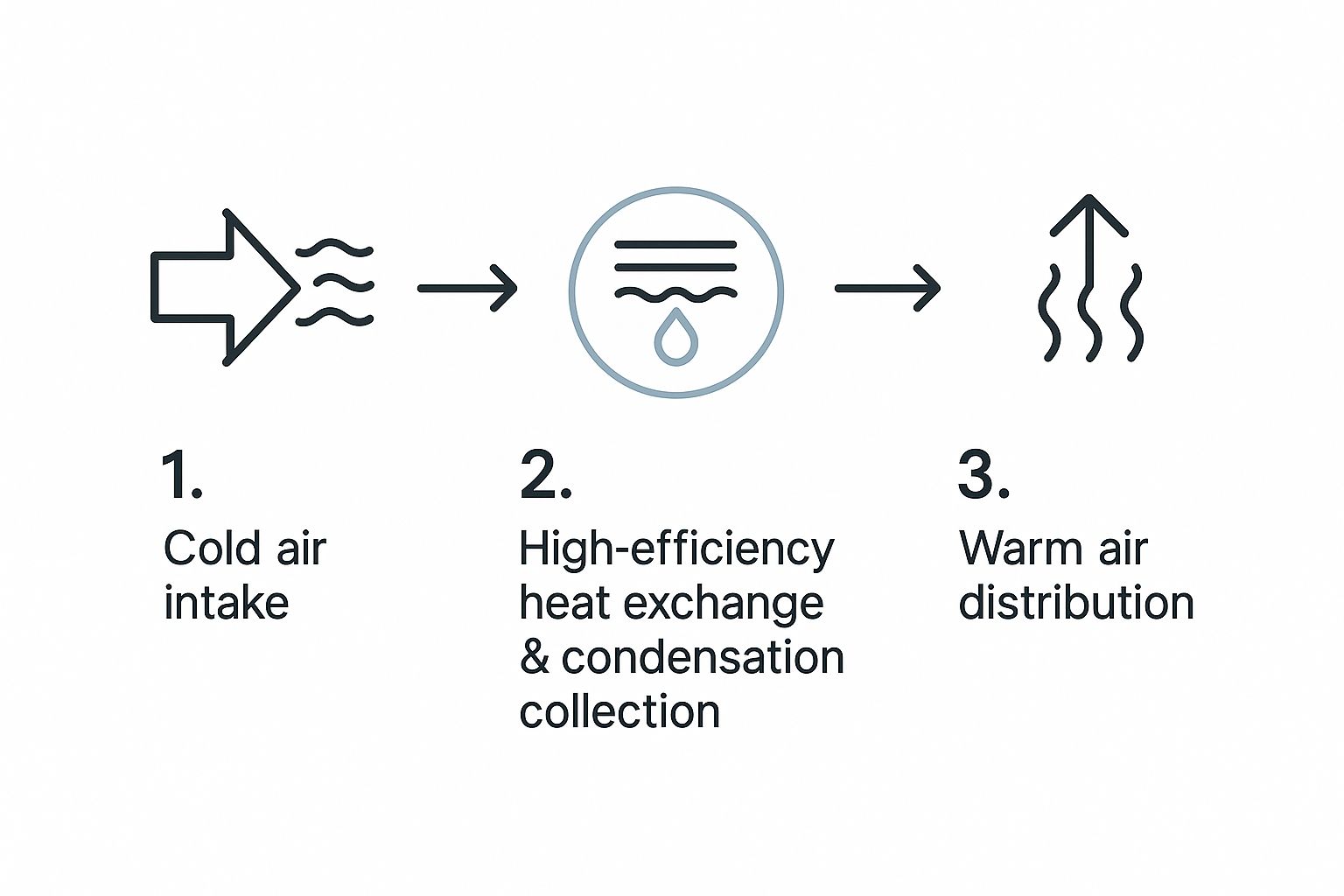

This image breaks down the basic process of how these high-efficiency units work.

It shows the closed-loop system that makes them so effective—using outside air for combustion and squeezing out every bit of heat before sending it through your building.

Navigating Codes, Permits, and Rebates

Finally, the planning phase isn't complete without tackling the paperwork. Every town and city has specific building codes for HVAC installations. Ignoring them can lead to failed inspections, fines, and having to redo expensive work.

Before any work starts, get in touch with your local building department to understand the permit requirements for installing a high efficiency furnace. A licensed contractor can usually handle this for you, making sure everything is documented and up to code.

This is also the perfect time to look for financial incentives. Many utility companies and government agencies offer great rebates for upgrading to energy-efficient equipment. These programs can seriously reduce your upfront cost. A quick search on your utility provider's website can often uncover hundreds or even thousands of dollars in savings.

Choosing the Right Furnace and Contractor

A successful furnace installation really comes down to two things: picking the right equipment and hiring the right team. If you get one of these wrong, the whole investment can be undermined, leaving you with years of frustrating inefficiency. Let’s walk through how to handle both of these critical decisions.

First, you have to speak the language of furnaces. Those product spec sheets can look like alphabet soup, but a couple of key terms tell you almost everything you need to know. The big one is the AFUE rating. An AFUE of 95% means that for every dollar you spend on fuel, 95 cents is converted directly into heat for your building.

Another crucial number is the BTU output, which is just a measure of the furnace's raw heating power. This absolutely must be figured out with a proper load calculation—not a quick guess based on square footage. An oversized unit will short-cycle constantly, wasting energy and wearing itself out. An undersized one will run nonstop and never hit your target temperature.

Decoding Furnace Types

Beyond the basic specs, high-efficiency furnaces operate in a few different ways. Each offers a different level of comfort and efficiency, so matching the type to your commercial space is key.

Single-Stage Furnaces: These are your basic "on" or "off" models, like a light switch. They're the most affordable high-efficiency option, but they can create noticeable temperature swings as the system cycles.

Two-Stage Furnaces: This is a big step up. These units have a "low" and a "high" setting, running on the quieter, more efficient low setting (around 65% capacity) most of the time. They only kick into high gear on the absolute coldest days, giving you more consistent heat.

Modulating Furnaces: This is the top-tier technology. Instead of just two stages, a modulating furnace adjusts its heat output in tiny increments—often as small as 1%. It runs almost continuously at a very low level, perfectly matching the building’s heating needs in real-time. The result is incredible energy savings and rock-solid indoor temperatures.

The warm air furnace market, dominated by these high-efficiency models, is a huge part of the global HVAC industry. It accounted for over USD 8.9 billion in 2024 and is only expected to grow. Why? Because these units provide fast, effective heat and have impressive lifespans of 15 to 30 years, often outlasting other systems. You can dig into the numbers in this market analysis on warm air furnaces.

Vetting Your HVAC Contractor

Once you have a good idea of the equipment you need, your focus should shift to finding the right installer. The quality of the installation is just as important as the quality of the furnace. A sloppy job can completely ruin the performance of even the most advanced unit.

A top-of-the-line, 97% AFUE modulating furnace installed improperly will perform worse than an 80% AFUE standard unit installed by a true professional. The expertise of the technician is a non-negotiable part of the equation.

When you're interviewing potential HVAC contractors, you aren’t just looking for someone to connect pipes. You need a partner with specific, hands-on experience in installing a high efficiency furnace in a commercial building like yours.

Here's a practical checklist to run through with every potential contractor:

Licensing and Insurance: Ask for their state license number and proof of liability and worker's comp insurance. This is non-negotiable and protects your business from any accidents.

Experience with High-Efficiency Systems: How many of these units have they installed in the last year? Can they give you examples of similar projects? They should be experts in setting up the required PVC venting and condensate drains.

Load Calculation Method: Confirm they will perform a Manual J load calculation. If they just want to size the unit based on square footage, that’s a red flag. Walk away.

Permits and Inspections: Do they handle all the local permits and schedule the final inspection? A professional company manages this entire process for you.

Warranties: What kind of warranty do they offer on their labor? This is separate from the manufacturer’s equipment warranty and shows how much they stand behind their work.

Don't assume a bigger company is automatically better. You should also read our guide on why bigger isn't always better when choosing an HVAC company. Look for a contractor who gives you a detailed, itemized quote, takes the time to answer your questions, and has a solid local reputation. Doing your homework here ensures your investment is in good hands.

What to Expect on Installation Day

The big day is here. After all the planning, your new high-efficiency furnace is ready to be installed. Knowing what’s coming will help you oversee the project with confidence and ensure everything goes smoothly from start to finish. From the moment the technicians arrive, it should be a well-oiled machine.

A professional installation team always starts by prepping the site. This isn’t just about rolling in the toolboxes. They should be laying down drop cloths and other protective coverings to keep your floors and nearby equipment safe from dust and scuffs. Your job is to make sure the immediate work area is clear, giving the crew a safe and accessible space to get the job done right.

The Removal and Prep Phase

First things first, the old furnace has to go. This is a critical step that has to be handled safely, beginning with shutting off the gas and electrical supply to the unit. The crew will then carefully disconnect all the existing ductwork, gas lines, and wiring before hauling the old, heavy furnace out of your building.

Proper disposal is a sign of a true professional. A reputable contractor won't just leave the old unit by the dumpster. They’ll manage its responsible disposal and recycling according to local regulations, which often have strict rules for handling things like refrigerants.

Once the old unit is out of the way, the real work of installing a high efficiency furnace begins. This part of the job often means making a few changes to your existing setup. For instance, the plenum—that's the big box connecting the furnace to your main ducts—might need to be resized or adjusted. Getting a perfect fit here is key to achieving optimal airflow and system efficiency.

Critical Connections and Venting

With the new furnace set in place, the team will turn their attention to the connections. This is where you’ll see one of the signature features of a high-efficiency model: the new PVC pipes for intake and exhaust. Unlike the old metal flues, these plastic pipes pull in fresh air for combustion from outside and safely vent the cooler exhaust gases.

The installer has to get the pitch of these pipes just right.

The vent pipes for a high-efficiency furnace need to slope back toward the furnace—usually about a quarter-inch per foot. This slope ensures the acidic condensation that forms inside drains properly, preventing it from freezing at the vent outside and shutting down your system in the middle of winter.

This brings us to another vital step: the condensate drain. High-efficiency furnaces are so good at pulling heat from the exhaust that water vapor condenses into liquid. This water has to go somewhere. The installer will run a drain line from the furnace to a floor drain or a small condensate pump. A bad drain setup is a common point of failure, often leading to water damage and system malfunctions.

Finally, the technicians will hook up the gas and electrical lines, making sure every connection is tight, secure, and up to code.

System Startup and Final Checks

The job isn’t over just because everything is connected. The final, and arguably most important, phase is the system startup and commissioning. This is where the technician fires up the furnace for the first time and runs through a detailed checklist to make sure it's operating safely and at peak performance.

These checks are non-negotiable and should always include:

Verifying Gas Pressure: Using a manometer, the technician will confirm the gas pressure is set precisely to the manufacturer’s specs for safe, efficient combustion.

Checking for Leaks: Every gas line connection is carefully checked with a leak detection solution to ensure there are absolutely no dangerous gas leaks.

Calibrating the Thermostat: The thermostat is tested to make sure it’s communicating properly with the furnace and cycling it on and off correctly.

Measuring Temperature Rise: The tech will measure the temperature difference between the air going in and the air coming out to confirm the furnace is heating within its specified range.

Only after these safety and performance checks pass with flying colors is the installation truly complete. The crew should clean up the entire work area, leaving your space just as they found it. A good contractor will also walk you through how to operate your new system and explain any maintenance needs before they pack up.

Optimizing Your New Furnace After Installation

The heat is on and the installation is done, but our work isn't finished just yet. To get every ounce of performance out of your new furnace, you need a smart post-installation strategy. This last phase is all about protecting your investment and making sure you get the efficiency and comfort you paid for.

Before your contractor packs up, walk through a final commissioning checklist with them. This is your chance to confirm everything is running exactly as it should. Don't be shy—ask them to show you the thermostat settings and verify that airflow feels balanced from room to room. A quick check now can prevent bigger headaches down the road.

Getting this right is crucial. The furnace market is booming, with the residential side alone expected to jump from USD 7.60 billion in 2024 to over USD 10.21 billion by 2032. People want efficiency and lower bills, which makes proper optimization more important than ever.

Creating a Proactive Maintenance Schedule

Long-term performance really comes down to consistent care. Your new high-efficiency furnace is a finely tuned machine, and a simple maintenance schedule is the key to keeping it that way. Trust me, proactive care is always cheaper than an emergency repair call.

The easiest and most critical task is changing the air filter. When a filter gets clogged, it restricts airflow and forces the blower motor to work harder. That wastes electricity and can lead to a system failure way sooner than you'd expect.

Here’s a practical schedule to stick to:

Monthly Checks: Just take a quick look at the air filter. In a busy commercial building, you’ll likely need to replace it every 30-60 days.

Annual Professional Servicing: Once a year, right before heating season kicks into gear, schedule a professional tune-up. A technician will clean key components, inspect the heat exchanger, and check all the electrical connections for safety.

Regular upkeep, including professional furnace and duct cleaning services, ensures your furnace operates at its best. Clean ducts mean your system isn’t fighting against dust and debris, which directly improves efficiency and the air quality for everyone in the building.

Integrating Smart Controls for Maximum Savings

To truly get the most out of your investment, you'll want to pair your new furnace with smart building controls. A modern smart thermostat does more than just turn the heat up and down; it actually learns your building's occupancy patterns and optimizes heating schedules on its own. This one simple upgrade can deliver an extra 10-15% in energy savings.

Think of a smart thermostat as the brain of your new HVAC system. It connects the high-efficiency hardware to your building's real-world usage patterns, ensuring you never waste a cent heating an empty space.

When you link your furnace to a building automation system (BAS), you unlock even more control. You can manage temperatures across different zones, watch energy consumption in real-time, and get alerts if the system flags a problem. This level of oversight makes it easier than ever to get the most out of your heating and cooling system. It’s the final step that turns your furnace from a standalone unit into an intelligent part of your building's operational strategy.

Common Questions About Furnace Upgrades

Even with a solid plan, a few questions always seem to pop up when you're thinking about a major furnace upgrade. It's completely normal. Building managers and property owners I talk to often have the same practical concerns about cost, compatibility, and what the new tech really means for their building day-to-day.

Let's cut through the noise and tackle the most common ones head-on.

What Is the Real Upfront Cost Difference?

There’s no getting around it—a high-efficiency furnace with a 90%+ AFUE rating will have a higher price tag. You’re typically looking at 25-50% more than a standard 80% AFUE model.

That extra cost covers the advanced components that make it so efficient, like the all-important secondary heat exchanger and the specific PVC venting materials it needs. But looking at that initial number alone is a mistake. For a commercial building, the energy savings over the furnace's 15- to 20-year lifespan almost always pay back that initial investment, and then some. Utility rebates can also take a nice chunk out of that upfront cost.

If you really want to get into the numbers, our guide on demystifying the cost of commercial HVAC systems breaks it all down.

What New Venting Is Required?

This is probably one of the biggest—and most important—changes. Standard-efficiency furnaces push hot exhaust out through a traditional metal chimney. High-efficiency units are different. They use a sealed, two-pipe PVC system that runs directly to an exterior wall or the roof.

Intake Pipe: Pulls fresh, clean air from outside for combustion.

Exhaust Pipe: Pushes out the much cooler exhaust gases.

This sealed system is a core part of its efficiency and is much safer. Your installation plan absolutely has to map out a route for these new pipes. A pro installer will make sure the pipes are pitched just right to drain condensation, which is a small detail that prevents huge problems down the road.

Can I Use My Existing Ductwork?

In most cases, the answer is "yes, but..." It always comes with the condition that a certified HVAC contractor needs to give your ductwork a thorough inspection first. It’s non-negotiable.

We need to confirm your ducts are correctly sized for the new furnace's airflow and that they're in good shape. High-efficiency furnaces often have variable-speed blowers that need well-designed ducts to work their magic. If your ducts are undersized or leaking, you simply won't get the efficiency you're paying for. We might need to seal some leaks or make a few modifications to ensure you get balanced, effective airflow.

Why Is the AFUE Rating So Important?

AFUE stands for Annual Fuel Utilization Efficiency. It’s the single most important number to look at. It’s a simple percentage that tells you how much of your fuel gets turned into usable heat versus how much is just wasted.

Think of it this way: a furnace with a 95% AFUE rating means 95 cents of every dollar you spend on fuel becomes heat. Only 5 cents is lost. An older 80% AFUE unit wastes four times as much—a full 20 cents of every dollar.

For a commercial property, that percentage isn't just a sticker on a machine. It translates directly into thousands of dollars in operational savings every single year. The higher the AFUE, the lower your utility bills and the smaller your building's carbon footprint. It’s a win-win.

Ready to upgrade your commercial heating system with confidence? The experts at Putnam Mechanical LLC have the experience to ensure your high-efficiency furnace installation is done right, maximizing your return on investment from day one. Contact us for a professional assessment at https://pmechanicalfl.com.

_edited%20copy.png)