Commercial Ice Machine Maintenance Tips for Reliable Performance

- Aug 16, 2025

- 13 min read

Proper commercial ice machine maintenance is more than just another item on your to-do list. It's a core part of a smart business strategy, one that directly protects your revenue, keeps customers safe, and makes your operations run smoothly. If you neglect it, you’re looking at inevitable breakdowns, potential health code violations, and utility bills that just keep climbing.

Why Ice Machine Maintenance Is a Business Priority

It’s easy to think of an ice machine as just another piece of equipment humming away in the background. That is, until it stops humming during a packed dinner rush on a sweltering July evening.

Suddenly, that out-of-sight, out-of-mind appliance becomes a critical point of failure. You're forced to send staff on frantic, costly ice runs and serve lukewarm drinks that can do real damage to your reputation. This is exactly why proactive maintenance isn't a chore—it’s an investment in keeping your doors open.

A neglected machine doesn't just fail overnight. It degrades slowly, working harder and guzzling more energy every single day.

The Hidden Costs of Neglect

An inefficient unit can subtly inflate your utility bills month after month, a creeping expense that quietly eats into your profits. Understanding how ice machine efficiency can impact your bottom line is the first step toward treating its upkeep as a financial priority.

Beyond the energy waste, the warm, damp environment inside an ice machine is a perfect breeding ground for mold, slime, and bacteria.

The real risk isn't just a machine that breaks down; it's the potential for a failed health inspection. A single violation tied to unsanitary ice can have serious consequences for your business's standing in the community.

Ignoring regular upkeep introduces some pretty significant financial burdens. In fact, commercial ice machine maintenance is a major operational cost in the hospitality sector. While the market keeps growing, these ongoing expenses create a real challenge for businesses that have to budget for parts, labor, and the lost profit that piles up during downtime.

From Chore to Strategy

When you start viewing maintenance through a strategic lens, the entire equation changes. Instead of just reacting to emergencies, you start preventing them. Consistent cleaning, filter changes, and system checks deliver tangible benefits that go far beyond just having ice on demand.

Protecting Revenue: You eliminate the risk of unexpected downtime and lost sales during your busiest hours.

Ensuring Customer Safety: It guarantees clean, sanitary ice that’s free from harmful contaminants.

Controlling Operational Costs: This keeps your utility bills in check by ensuring the machine runs at peak efficiency.

Extending Equipment Lifespan: Proactive care will significantly prolong the life of your expensive equipment, protecting your investment.

Your Essential Cleaning and Sanitizing Protocol

A solid cleaning and sanitizing routine is the absolute cornerstone of keeping a commercial ice machine running right. This is way more than just a quick wipe-down; it directly affects your ice quality, the machine's efficiency, and most importantly, your customers' safety. Let’s walk through the right way to deep-clean your machine.

First things first, you need to get your supplies in order. You absolutely must use manufacturer-approved solutions to avoid wrecking sensitive components. Trust me, generic cleaners just won't cut it and can cause some seriously expensive damage.

Assembling Your Cleaning Toolkit

Before you even think about starting, make sure you have everything you need right there with you. Nothing kills momentum and leads to missed steps like having to hunt for supplies mid-clean.

Nickel-Safe Scale Remover: This is non-negotiable. Using a standard descaler can eat away at the nickel plating on the evaporator, and that’s a repair bill you don’t want to see.

Food-Grade Sanitizer: The solution has to be approved for food contact surfaces. This ensures the ice you serve is safe for people to actually consume.

Soft-Bristle Brushes: Grab a few different sizes. You'll need them to get into tight corners and clean small parts like the distribution tube without scratching anything up.

Clean Cloths and Protective Gloves: Use lint-free cloths for wiping, and always wear gloves to protect your hands from the cleaning chemicals.

Now for the most critical step before you touch a single thing inside that machine: kill the power at the circuit breaker. This completely removes the risk of electrical shock or the machine kicking on while your hands are inside.

Disassembly and Component Inspection

With the power safely off, you can start taking out the key internal parts. Most modern machines are built so you can remove these components easily without any tools.

Gently take out the water curtain, the ice thickness probe, and the water distribution tube. As you pull each part, give it a close look. See a chalky, white buildup? That's mineral scale. Is it more of a pinkish or black slime? That’s likely mold or other organic gunk. Figuring out what kind of buildup you have gives you a better idea of your water quality and how often you really need to be cleaning.

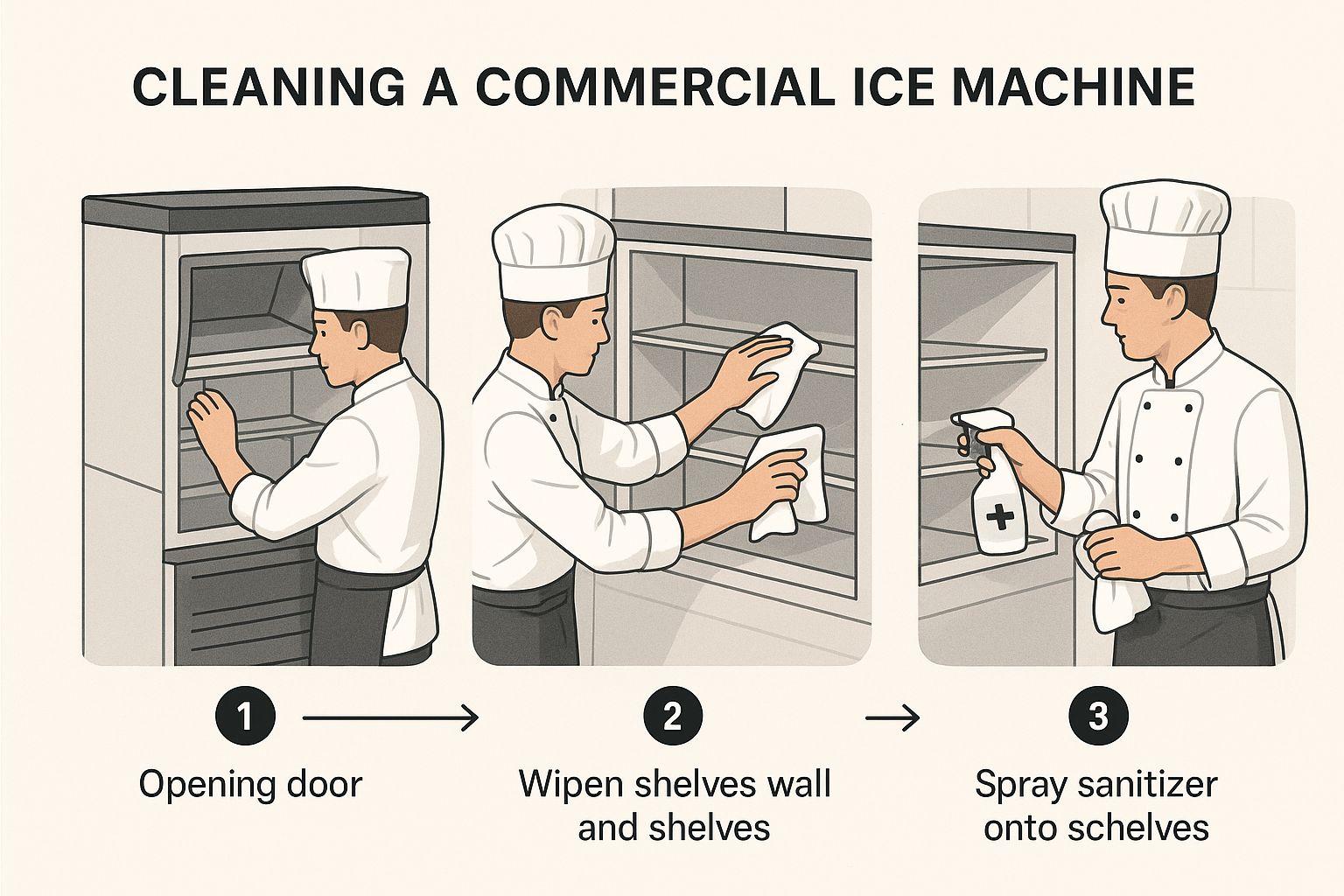

This image breaks down the cleaning flow you should follow to maintain your machine's interior properly.

Executing the Cleaning Cycle

Alright, it’s time to let the machine do some of the hard work. Just follow your manufacturer's guide to start the "Clean" or "Wash" cycle.

This automated cycle is designed to circulate the cleaning solution through the entire water system. It dissolves mineral scale from the evaporator plate and other internal pathways you could never reach by hand. Make sure you measure and add the nickel-safe scale remover exactly as the manual says—using too much or too little can either be ineffective or cause damage.

Here's the golden rule I always follow: clean first, then sanitize. Cleaning gets rid of the mineral deposits and grime. Sanitizing kills the microorganisms. If you do it out of order, the sanitizer can't do its job on a dirty surface.

Once the cleaning cycle is finished, it's time for the sanitizing step. Mix your food-grade sanitizer according to the label's directions. I find a spray bottle works best to apply it to all the parts you took out and the interior surfaces of the food zone. You want to make sure you get complete coverage.

Let that solution sit for the recommended contact time, which is usually around 10 minutes. This is what actually kills the bacteria and mold. The final, and arguably most important, step is a thorough rinse. Flush the whole system and all the components with fresh water until you can't smell any chemicals. Any residue left behind will absolutely taint the taste and safety of your ice.

Preventive Maintenance You Should Never Skip

A deep cleaning cycle is great for tackling slime and scale, but it's the simple mechanical checks that really prevent those sudden, middle-of-a-rush breakdowns. This is like looking under the hood of your car. These inspections are all about the systems that keep your machine breathing, cooling, and pumping out clean ice.

Ignoring these checks is asking for trouble. A clogged filter or a dirty coil seems small, but it can quickly snowball into a major component failure. This is where proactive commercial ice machine maintenance shifts from a chore to a smart way to protect your equipment.

Keep The Air Flowing

Think of the air filters and condenser coils as your machine’s lungs. Just like you can’t run a marathon while struggling for air, your ice machine can't work efficiently if its airflow is choked off.

Start with the air filter. It's usually right on the outside of the unit, and its whole job is to catch dust, grease, and whatever else is floating around your kitchen. When that filter gets clogged, the compressor has to work way harder to get rid of heat. This drives up your energy bill and can easily cause the machine to overheat and shut down completely.

A dirty air filter is one of the most common—and easily preventable—causes of an emergency service call. Cleaning it monthly with warm, soapy water is a simple ten-minute task that can save you hundreds in repair costs.

The condenser coils need love, too. These are the fins that look like a radiator, and they’re responsible for releasing heat. Over time, they get covered in a blanket of grime that acts like insulation, making it nearly impossible for the machine to cool itself. A quick, gentle cleaning with a soft brush every six months is all it takes to keep things running cool.

Protect Your Water Quality

The water going into your machine is just as critical as the air cooling it. That external water filter isn't just an accessory; it's your first line of defense against internal damage.

Even if your local water is considered "good," it’s still full of minerals that will build up as hard scale inside your machine. Your water filter is the only thing stopping those minerals from wrecking delicate parts like the evaporator plate and water pump.

Stick to the Schedule: Water filter cartridges don't last forever. Following the replacement schedule—usually every six months—is non-negotiable if you want to protect your investment.

Prevent Internal Damage: A spent filter is worthless. It lets scale form, which restricts water flow, creates misshapen ice, and eventually destroys key components. You can learn more about how regular maintenance prevents costly equipment breakdowns in our detailed guide.

Guarantee Great Ice: A fresh filter doesn't just protect the machine; it removes sediment and chlorine, which makes your ice taste better and look clearer.

Clean, reliable ice is more in demand than ever. The commercial ice machine market hit around USD 1.4 billion in 2024 and is expected to climb to USD 1.86 billion by 2033. This growth is why manufacturers are adding advanced water purification systems, proving just how critical water quality is. You can read more about this growing market and its technological advancements on Business Research Insights.

Preventive Maintenance Schedule

To keep things simple, here’s a straightforward schedule you can follow. Sticking to this routine is the best way to ensure your ice machine stays reliable and efficient.

Task | Frequency | Importance |

|---|---|---|

Clean or Replace Air Filters | Monthly | High |

Deep Clean & Sanitize Ice Bin | Quarterly | High |

Replace Water Filter Cartridge | Every 6 Months | Critical |

Clean Condenser Coils | Every 6 Months | High |

Inspect Water Lines & Drains | Annually | Medium |

Professional Tune-Up | Annually | High |

Following this simple checklist will drastically reduce unexpected failures and keep your machine running like it should for years to come.

Troubleshooting Common Ice Machine Problems

Even with a perfect maintenance schedule, things can still go wrong. When your ice machine starts acting up, the key is to stay calm and work through the issue methodically. Don't immediately assume the worst and call for a major repair. A few simple checks can often pinpoint the problem and save you the cost of an unnecessary service call.

This isn't about pulling out the toolbox and attempting complex repairs; it’s about being the first responder. Knowing the common symptoms and their likely causes empowers you to solve minor issues on your own. At the very least, you can give a technician valuable information to speed up the repair. Think of it as triage for your machine.

The Machine Produces No Ice

This one is always alarming, but it often has a surprisingly simple fix. Before you panic, let's walk through a few potential culprits that might be interrupting the ice-making cycle.

Your first stop should always be the water supply. Is the water inlet valve fully open? It's not uncommon for it to get bumped or turned off by accident. A quick look can solve the problem instantly. If the valve is open, trace the water line to look for any kinks or clogs that could be restricting flow.

Next, have a look at the machine’s control panel. Sometimes, a high-limit switch gets tripped due to overheating. This often happens when air filters or condenser coils are dirty, which prevents the machine from cooling itself down properly. Many units have a simple reset button that can get you back up and running after you've addressed the airflow issue.

A scenario I see all the time is a machine that sounds like it's running—you can hear the compressor kick on—but no ice ever drops. This almost always points directly to a water supply problem, like a clogged screen on the water inlet valve that’s blocking water from ever reaching the evaporator plate.

The Ice Quality Is Poor

If your machine is making ice, but it’s thin, hollow, cloudy, or just misshapen, the problem is almost always related to water flow or a dirty component. This is a clear signal that your commercial ice machine maintenance routine needs a little more attention.

Poor-quality ice cubes are often caused by one of these issues:

A Dirty Evaporator Plate: Mineral scale or slime buildup prevents water from freezing evenly across the plate. This results in weak, incomplete, or hollow cubes.

Low Water Flow: A partially clogged water filter or a failing water pump can reduce the amount of water cascading over the evaporator, which leads to thin ice.

Incorrect Water Temperature: If the incoming water is too warm, the machine will struggle to freeze it properly during its cycle time, producing slushy or soft ice.

If you're dealing with a more serious issue like a complete refrigeration failure, it might be time for professional help. For those urgent situations, our [emergency commercial refrigeration repair guide](https://www.pmechanicalfl.com/post/emergency-commercial-refrigeration-repair-guide) can walk you through what to do while you wait for a technician.

The Machine Is Leaking Water

A puddle of water around your ice machine is a red flag you can't ignore. The leak could be coming from a few different places. Check the water lines leading into the machine for any loose fittings or cracks. You'll also want to inspect the drain line to make sure it isn't clogged with debris, which would cause water to back up and overflow.

Sometimes, a leak can start from inside the ice bin itself if its drain is blocked. A simple cleaning of the bin drain can often resolve this messy problem. Running through these quick diagnostics can help you identify whether you have a simple fix or a situation that requires a professional.

Knowing When to Call a Professional Technician

Even the most dedicated restaurant owner has limits. While handling routine cleaning and basic troubleshooting is a great way to stay on top of things, some issues just aren't a DIY job. You need specialized tools and the kind of expertise that only comes with experience.

Trying to tackle complex repairs without proper training can backfire, fast. You could end up causing even more damage, creating serious safety risks, and you might even void your machine's warranty. Knowing where to draw the line is a crucial part of smart commercial ice machine maintenance. It’s about protecting your equipment, your staff, and your business.

Red Flags That Demand a Professional

Some problems are clear warnings of a much deeper issue brewing inside your machine. If you spot any of these signs, it's time to stop what you're doing and call a certified technician.

Don't hesitate if you see:

Signs of a Refrigerant Leak: An oily film building up around the copper lines or a faint hissing sound are dead giveaways. Refrigerant is a hazardous material and legally requires a certified professional to handle it safely.

Major Electrical Faults: Is the machine constantly tripping the circuit breaker? Do you smell something like burning plastic? Shut the power off immediately and get a pro on the phone. Electrical work is incredibly dangerous.

A Silent Compressor: During the freeze cycle, you should hear the compressor kick on with a low hum. If the machine has power but the compressor is dead silent, you’re likely looking at a failed compressor or another major electrical component failure.

Trying to fix these issues yourself is a gamble you can't afford to take. The risk of personal injury or causing irreversible damage to a machine worth thousands of dollars is far too high.

Making the Service Call Effective

When you do call a technician, being prepared can make the whole repair process go a lot faster—and smoother. Have this information handy before you pick up the phone:

Machine Make and Model: You can usually find this on a sticker or plate just inside the front panel.

A Clear Description of the Problem: Be specific. Instead of just saying "it's broken," try something like, "It's making a loud grinding noise during the harvest cycle, and the ice is coming out thin and wet."

Recent Maintenance History: Let them know the last time it was professionally serviced or when you last ran a full cleaning cycle.

Giving them this level of detail helps a technician diagnose the problem more accurately, often letting them bring the right parts on the very first visit.

The global commercial ice maker market is on track to hit USD 3.5 billion by 2032, and all this new technology demands specialized maintenance. You can find more details on these ice maker market trends from Metastat Insight. Just like modern HVAC systems, these machines are becoming more complex, highlighting why expert service is so important—a point we cover in our guide on what commercial AC repair services include.

Frequently Asked Questions About Ice Machine Care

Even with a detailed guide in hand, a few specific questions about keeping your commercial ice machine running always seem to pop up. Getting straight answers is the best way to feel confident managing your equipment. Here are a few of the most common things we hear from business owners just like you.

Answering these practical questions helps bridge the gap between knowing what to do and actually doing it, making sure you can handle small issues before they snowball.

How Often Does My Machine Need Professional Service?

Even if you’re a rockstar with your own cleaning schedule, you absolutely need to get a professional service call on the calendar at least every six months. While your in-house cleaning tackles the daily grime, a certified technician performs a much deeper, more technical check-up.

They have the specialized tools to:

Check refrigerant levels and pressures—this is critical for cooling efficiency.

Clean the tough-to-reach spots, like the condenser coils and internal tubing.

Calibrate all the sensors and controls to make sure the machine is running to factory specs.

Think of it as a professional tune-up that keeps major, and very expensive, breakdowns from happening. This level of care is just as vital for your other cooling systems; you can learn more about how regular refrigeration maintenance can prevent major food loss in our related article.

What Is the Right Type of Ice Machine Cleaner to Use?

This is a huge one, and it can’t be stressed enough: always use a nickel-safe scale remover that is specifically made for ice machines. Your machine’s evaporator plate—the part that actually freezes the water—is coated in nickel, and it's surprisingly easy to damage with harsh, acidic cleaners.

Using the wrong chemical can permanently etch or corrode that nickel plating. When that happens, you’ll see uneven freezing, poor ice quality, and eventually, a component failure that will cost you thousands to replace. To be safe, always double-check your machine's manual for manufacturer-approved solutions.

Never, ever ignore the "Clean" or "Descale" indicator light, even if the machine seems to be chugging along just fine. That light is your machine’s built-in reminder that a cleaning cycle is due. Delaying it allows scale to harden, making it a nightmare to remove and seriously increasing the risk of a shutdown.

Can I Just Use Tap Water in My Machine?

You can, but it's a terrible idea unless you have a proper filtration system in place. Standard tap water is loaded with dissolved minerals and sediment. As the water freezes into cubes, all those impurities get left behind, forming a hard, chalky buildup called scale.

This scale is your machine's worst enemy. It clogs up water lines, coats sensors so they can't read correctly, and insulates the evaporator plate, forcing your machine to work much harder and longer to produce ice.

A high-quality water filtration system is honestly one of the best investments you can make. It protects your equipment, makes the ice taste and look better, and drastically cuts down on how often you have to do a heavy descaling.

When routine checks aren't enough and you need an expert to step in, the team at Putnam Mechanical LLC is ready to help. We provide reliable commercial ice machine maintenance and repair to keep your business running smoothly.

_edited%20copy.png)