A Guide to Installing AC Unit Systems in Commercial Spaces

- Sep 7, 2025

- 16 min read

Installing a commercial AC unit is a big job, and the real work starts long before anyone picks up a tool. Success is all in the upfront planning. Getting it right from the beginning means carefully assessing the site, running accurate load calculations, and dealing with local building codes.

Planning Your Commercial AC Unit Installation

A solid commercial AC installation is built on a strong foundation of planning. This isn't just about picking a spot for the unit; it's a strategic phase where you sidestep expensive mistakes and ensure the system runs efficiently and safely for years to come.

This careful preparation is more important than ever. The U.S. HVAC market was valued at a massive $30.41 billion in 2023 and is only getting bigger. Proper planning makes sure your investment pays off in operational efficiency instead of becoming a constant headache.

Conducting a Thorough Site Assessment

The first real step on the ground is a deep dive into the building's unique layout and structure. This isn't a quick walk-through. If you're putting a unit on the roof, you absolutely need a structural engineer to confirm the roof can handle the operational weight—especially when you factor in things like snow or heavy rain.

Next, you have to look at the existing infrastructure. Can the electrical panel handle the power draw from a new, modern system, or are you going to need an expensive service upgrade? What about the ductwork? It's common to find leaks, poor insulation, or incorrect sizing that will choke the performance of even the best new unit. Finding these issues now saves a world of trouble later on.

Nailing the Load Calculation

One of the biggest—and most damaging—mistakes we see is improper unit sizing. Just measuring square footage is nowhere near enough for a commercial space. A real load calculation, usually done with Manual J software, looks at dozens of factors:

Building Occupancy: How many people are in the space at its busiest?

Heat-Generating Equipment: Think computers, servers, kitchen appliances, and heavy machinery. They all add to the heat load.

Insulation and Windows: The R-value of the insulation and the type of windows (and which way they face) have a huge impact on heat gain.

Building Orientation: A building that gets blasted by the afternoon sun will have totally different cooling needs than one that's mostly shaded.

For example, a restaurant kitchen has completely different cooling demands than an office of the exact same size. You can learn more about this in our guide on https://www.pmechanicalfl.com/post/how-to-choose-the-right-cooling-system-for-a-busy-kitchen.

Key Takeaway: An undersized unit runs nonstop without ever hitting the set temperature, burning itself out. An oversized unit will short-cycle, turning on and off so frequently that it never properly dehumidifies the air. The result? A cold, clammy building and premature equipment failure.

Navigating Codes and Permitting

Finally, don't forget the paperwork. Every commercial installation has to follow local building codes and requires permits. These rules are in place to ensure everything is safe, from the electrical work to the structural support and refrigerant handling. Before any work starts, it's essential to review the detailed Construction Drawings to understand the project's exact specifications and layout.

Trying to skip this step is a recipe for disaster. You're looking at failed inspections, hefty fines, and potentially having to rip everything out and start over. Get in touch with your local building department early on. Understand what they need, submit your plans, and get those permits in hand. This administrative work is just as critical as turning the wrenches.

Assembling Your Tools and Safety Gear

When you're installing a commercial AC unit, showing up unprepared is not an option. Your professionalism and the quality of your work are judged the moment you open your truck. A complete, well-organized toolkit tells the client you’re serious and competent.

Think about it. Trying to diagnose a complex electrical fault with a cheap multimeter or pulling a vacuum on a large system with an undersized pump isn't just an inconvenience—it's a recipe for callbacks, system failures, and a damaged reputation. This is where a successful installation truly begins.

Your Core Mechanical and Diagnostic Toolkit

Every seasoned technician has their go-to tools, but there's a standard loadout that's non-negotiable for commercial jobs. These are the instruments that let you measure, manipulate, and verify every step of the installation. Without them, you’re flying blind.

Having the right equipment from the start is about more than just convenience; it's a foundational element of ensuring long-term system health. Understanding the key benefits of upgrading to a modern commercial AC system also helps you explain the value of a professional installation to clients.

Before you ever step on-site, a thorough tool check is essential. Here’s a quick rundown of what you’ll need at a minimum.

Essential Toolkit for Commercial AC Installation

This checklist covers the absolute must-haves for a complete and professional setup, broken down by function. Double-check your truck to make sure you have every one of these ready to go.

Category | Tool/Equipment | Primary Use |

|---|---|---|

Refrigeration | Digital Manifold Gauge Set | Accurately reading system pressures for charging and diagnostics. |

Refrigeration | Dual-Stage Vacuum Pump & Micron Gauge | Removing moisture and non-condensables from refrigerant lines. |

Refrigeration | Brazing Kit (Oxy-Acetylene) | Creating strong, leak-proof joints on copper refrigerant lines. |

Refrigeration | Nitrogen Tank & Regulator | Purging lines during brazing to prevent internal oxidation. |

Line Set Work | Tubing Cutter, Flaring & Swaging Tools | Cutting, shaping, and connecting copper tubing for a perfect seal. |

Electrical | Clamp-On Multimeter | Verifying voltage, checking amperage, and testing circuit continuity. |

Electrical | Wire Strippers & Crimpers | Making secure low and high-voltage connections. |

Electrical | Insulated Screwdrivers & Nut Drivers | Safely working inside electrical panels and disconnects. |

Safety | Lockout/Tagout (LOTO) Kit | Ensuring circuits cannot be accidentally re-energized during work. |

Safety | Personal Protective Equipment (PPE) | Includes safety glasses, gloves, hard hat, and steel-toed boots. |

Having this gear organized and in good working order isn’t just best practice—it’s what separates the pros from the amateurs.

Electrical and Safety Essentials

Working on commercial HVAC systems means dealing with high-voltage electricity. That makes your safety gear just as critical as your mechanical tools. There is absolutely no room for shortcuts here, as a single mistake can have devastating consequences.

This part of your toolkit should be meticulously maintained and always within arm's reach.

Key Electrical Tools: A reliable clamp-on multimeter is your best friend for verifying voltage and checking amp draws. You'll also need quality wire strippers, crimpers, and a set of insulated screwdrivers for working safely inside panels.

Personal Protective Equipment (PPE): This isn't optional. Always have safety glasses, insulated gloves for electrical work, a hard hat (especially on construction sites), and steel-toed boots.

The most important piece of safety gear is your Lockout/Tagout (LOTO) kit. It’s the only thing that ensures a circuit can’t be accidentally powered on while you're working. Never touch a wire without properly locking and tagging out the power source first. It's a rule that can save your life.

Executing the Mechanical and Electrical Setup

With the planning done and the right tools in hand, it’s time to bring the project to life. This is where careful measurements and precise work turn blueprints into a reliable, efficient commercial HVAC system. We're getting our hands dirty, installing the AC unit itself and handling both the heavy mechanical parts and the delicate electrical connections that make it all work.

This is the most hands-on part of the installation. It takes a mix of muscle to position the heavy equipment and a steady hand for connecting refrigerant lines and control wiring. A mistake here isn't just a cosmetic issue—it can cause vibrations, leaks, and electrical shorts that lead to a system failing years before its time.

Placing and Securing the Core Components

The first big physical job is setting the system's two main pieces: the indoor air handler and the outdoor condenser. For most commercial buildings, the outdoor unit is a packaged system that goes on the roof to save space and keep noise down. This usually means coordinating with a crane operator to carefully lift the unit into place.

Once it's positioned on its pre-approved curb or stand, the unit has to be secured. This isn't just to keep it from moving; it’s about controlling vibration. We always install vibration isolation pads between the unit and the mounting surface. These thick rubber or spring-loaded pads absorb the constant hum from the compressor and fans, stopping that noise from traveling through the building's structure and becoming a headache for the people inside.

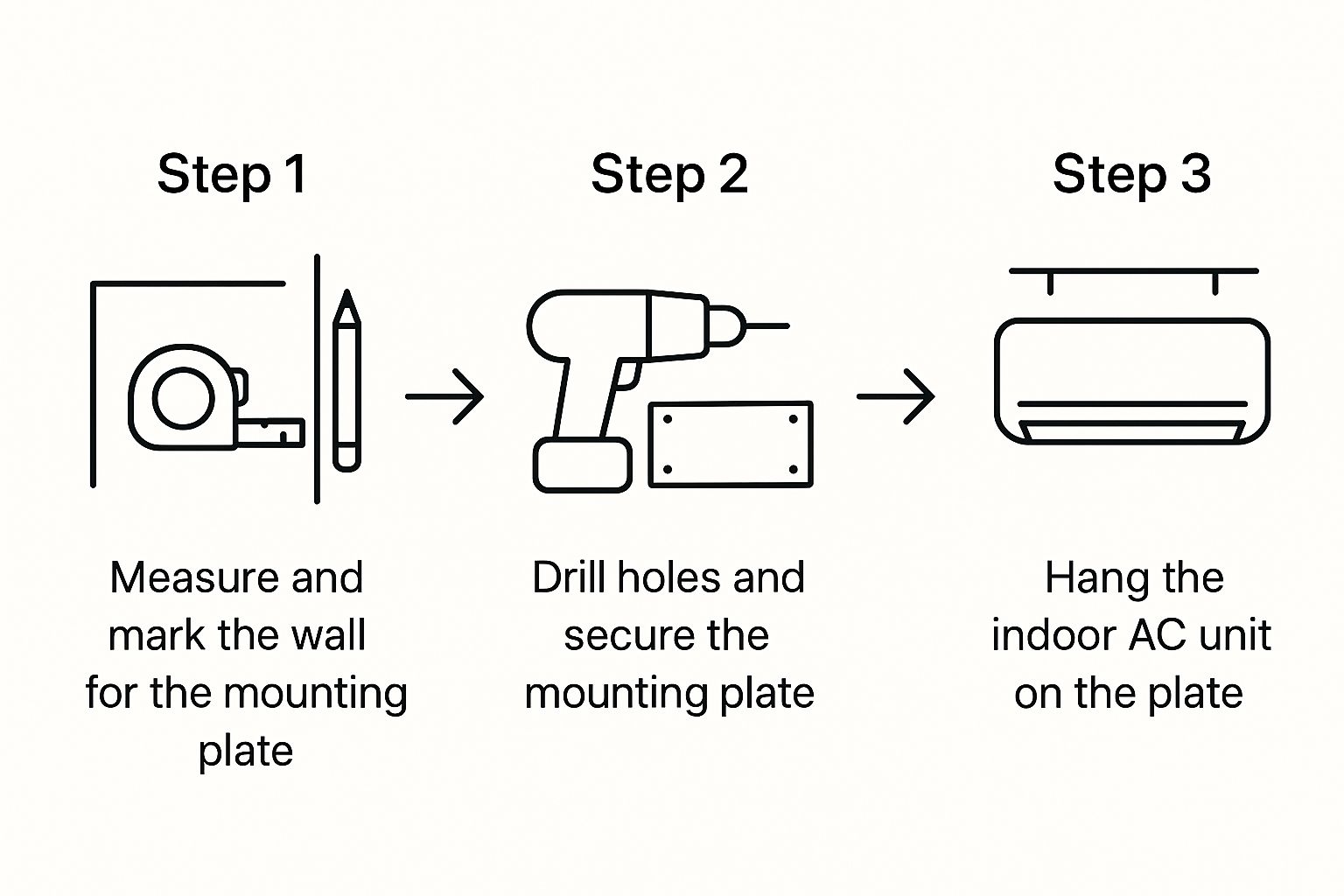

The image below shows the basic steps for mounting an indoor unit, which works on the same principle of measure twice, fasten once.

As you can see, getting the measurements and markings right from the start is what guarantees the unit hangs level and secure when the job is done.

Mastering the Refrigerant Line Set

With the units mounted, the next critical task is running the refrigerant lines between them. This copper tubing is the circulatory system of the AC, and getting perfect, leak-free connections is a skill learned over time. It all comes down to three key techniques: cutting, flaring, and brazing.

Clean Cuts Are Non-Negotiable. You have to use a sharp tubing cutter, never a hacksaw. A clean, square cut provides the perfect base for a solid connection. After cutting, always deburr the inside edge of the pipe to clear out any copper shavings that could otherwise get into the system and wreck the compressor.

Perfecting the Flare. For fittings that use flare nuts, the flare has to be flawless. You're aiming for a smooth, even cone that will sit perfectly flush against the fitting. A flare that’s too small won’t seal, and one that’s cracked or too big will leak under pressure. A little drop of refrigerant oil on the flare before tightening helps it seat properly without damaging the soft copper.

Brazing with Precision. Brazing creates a permanent, high-strength bond that can handle the system's high pressures. The secret to a strong, clean joint is purging the copper lines with a slow, steady flow of nitrogen while you heat the connection.

Pro Tip: The nitrogen purge is a step you can't afford to skip. When you heat copper with oxygen present, it creates a black, flaky scale (cupric oxide) inside the pipes. This scale will break loose when the system starts up, contaminating the refrigerant oil and clogging sensitive parts like the expansion valve. It’s a surefire way to cause a catastrophic, expensive failure down the road.

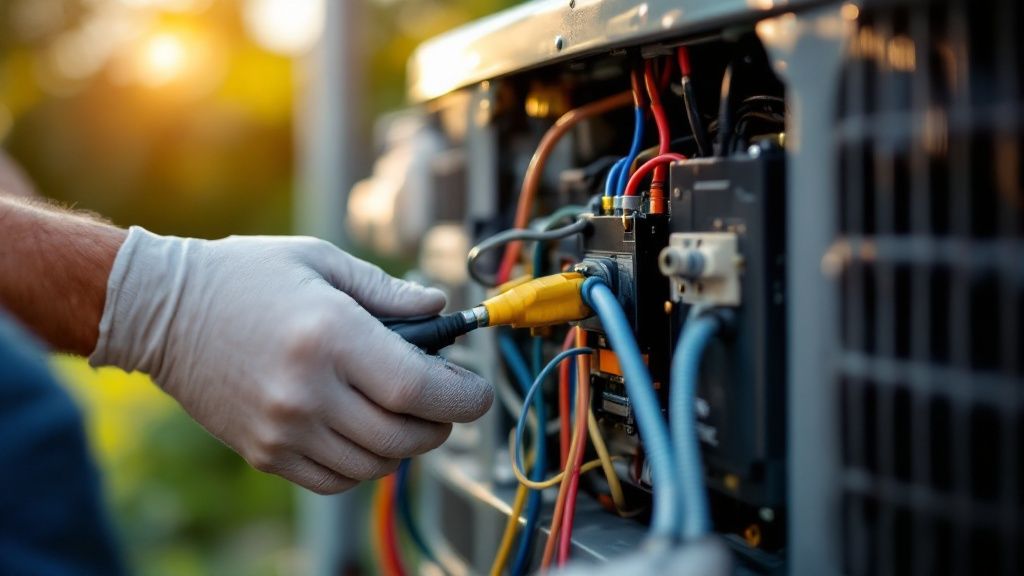

Navigating the Electrical Connections

The last piece of the physical installation is the electrical work. This covers both the high-voltage power needed to run the compressor and fans, and the low-voltage wiring for the thermostat and controls. Safety is everything here.

The first step is always running the high-voltage wire from the main electrical panel to a disconnect box located within sight of the outdoor unit. This is required by code and is a crucial safety feature that lets a technician kill the power right at the unit before starting any service.

When making your connections, double-check that all wires are properly sized for the unit's amperage draw, which you'll find in the manufacturer's specs. Use a quality wire stripper to avoid nicking the copper, and make sure every connection—in the panel, the disconnect, and the unit itself—is torqued down tight. A loose connection can overheat and become a serious fire hazard. If you have any doubts about your panel, it's a good idea to know how to check if a circuit breaker is bad to rule out other problems.

Low-voltage control wiring is less dangerous but just as critical for the system to work right. You'll typically run an 18-gauge, multi-conductor wire from the air handler to the thermostat.

Keep it Tidy: Route the thermostat wire neatly. Try to avoid running it right alongside high-voltage lines, which can cause electrical interference and make the thermostat act up.

Color Code Consistency: Stick to the standard color code (R for power, Y for cooling, G for fan, etc.) at both the thermostat and the unit's control board. Getting these wires mixed up is one of the most common reasons a new system won't start.

Secure Connections: Strip just enough insulation to get a good connection without leaving bare wire exposed. Make sure the small terminal screws on the control board are snug but not overtightened.

Once the mechanical and electrical work is done, the system is officially installed. Now, it’s time to get it ready to run by pulling a vacuum and charging it with refrigerant.

Mastering System Evacuation and Charging

With the heavy lifting done and the electrical work buttoned up, we’re heading into the most technical part of any AC install. This is where precision and patience really pay off, setting the stage for the system's long-term health and efficiency. It’s all about creating a perfect, closed-loop environment for the refrigerant to do its job.

This stage—evacuation and charging—is the absolute heart of the refrigeration cycle. Trying to rush this or skip steps is the fastest way I’ve seen to cause premature component failure, especially when it comes to the compressor. The work here is less about muscle and more about focus and a solid grasp of thermodynamics.

The Critical Importance of a Deep Vacuum

Before a single drop of refrigerant goes into the lines, you have to get everything else out. That means all the air and, most importantly, every last trace of moisture from the copper line set and indoor coil. We call this process evacuation, and it is absolutely non-negotiable.

When moisture gets mixed in with refrigerant, it forms a nasty, corrosive acidic sludge that eats away at the compressor's internal windings and other metal parts from the inside out. Air is just as bad. As a non-condensable gas, it gets trapped in the condenser coil, which drives up head pressure and makes the compressor work way harder than it should. The result? Higher energy bills and a significantly shorter lifespan for the unit.

The goal isn't just to get some air out; it's to pull a deep vacuum. The industry standard is to evacuate the system down to 500 microns or lower. Your standard set of analog gauges can’t even read this low, which is why a digital micron gauge is an essential tool for any serious professional.

The Step-by-Step Evacuation Process

Pulling a proper vacuum is a methodical game. You’re essentially proving that the system is perfectly sealed and completely dry before you move on.

Hook Up Securely: Connect your vacuum pump to the system with high-quality, large-diameter vacuum hoses. A pro tip: using a core removal tool on the service ports can dramatically speed things up by creating a much less restrictive path for air to escape.

Start the Pump: Open the valves on your manifold gauge set and fire up the vacuum pump. You'll see the pressure drop quickly right at the beginning.

Monitor with a Micron Gauge: Keep a close eye on your digital micron gauge. The reading will slowly tick down as the pump removes the last bits of air and boils off any moisture inside the lines.

Perform a Decay Test: Once you hit that 500-micron target, isolate the system from the pump by closing the manifold valves. Now, watch the micron gauge for about 15-20 minutes. If the reading stays steady or only rises a tiny bit, you've got a tight, dry system. If it shoots up quickly, you have a leak that needs to be found and fixed.

A rapid rise during a decay test almost always points to a leak at a flare fitting or braze joint. If you see a slow, steady rise that eventually levels off, it usually means there's still moisture in the system boiling off. That's your cue to keep pulling the vacuum a bit longer.

Charging the System with Precision

Once you’ve proven the system is tight and dry, it's time to add its lifeblood: the refrigerant. The amount, or "charge," has to be exact. An undercharged system won't cool right and can starve the compressor of oil. An overcharged system is even worse—it can cause liquid refrigerant to flood back to the compressor, leading to catastrophic damage.

The global demand for effective cooling is skyrocketing. The air conditioning market is projected to grow from around USD 129.36 billion in 2025 to USD 221.85 billion by 2032. This growth just underscores how critical proper installation and maintenance are for keeping these systems running efficiently. You can learn more about the trends in the air conditioning systems market.

There are three primary methods for charging a unit, and the right one depends on the equipment and conditions.

Charging by Weight: This is the most accurate method and should always be your go-to. The manufacturer's data plate on the outdoor unit tells you the exact weight of refrigerant needed for the unit and a standard line set length (usually 15 feet). You just use a digital refrigerant scale to weigh the exact amount out of the cylinder and into the system, adding a specified amount for any extra line set length.

Charging by Subcooling: This method is for systems that have a Thermal Expansion Valve (TXV). Subcooling is a measure of how much the liquid refrigerant has cooled below its saturation temperature. You measure the liquid line pressure, convert it to a saturation temp with a P/T chart, then measure the actual liquid line temperature. The difference is your subcooling, which you then compare to the target on the unit's data plate.

Charging by Superheat: This is the method for systems with a fixed orifice or piston metering device. Superheat measures how much the vapor refrigerant has heated above its saturation temperature. You follow a similar process, but this time using the suction line pressure and temperature. The correct superheat target changes with indoor and outdoor temps, so you'll need the manufacturer's charging chart to dial it in perfectly.

Just like AC units, commercial refrigeration equipment is incredibly sensitive to a proper charge. For more on that, you can check out our guide on how to keep your commercial refrigerator running at peak performance.

Commissioning the System for Peak Performance

Getting the AC unit mounted and hooked up is a huge step, but the job isn't finished. Now comes the most critical phase: commissioning. This is where we systematically test, tweak, and double-check every part of the system to make sure it runs exactly like the manufacturer intended.

If you skip this, it's like building a race car and never bothering to tune the engine. You’re just leaving performance, reliability, and a lot of money on the table. A properly commissioned system means a happy client, far fewer callbacks, and proof that you did the job right from the very start.

Initial Electrical and Mechanical Verifications

Before you even think about flipping the switch, a full round of safety and operational checks is non-negotiable. This isn't just a quick once-over; it's a methodical pre-flight checklist for the entire HVAC system.

Start right at the electrical disconnect. Grab your multimeter and get to work:

Confirm Voltage: Make sure the incoming voltage is within the manufacturer's specified range, which is usually +/- 10%. Bad voltage is a fast way to kill a motor or compressor.

Check Phasing: On three-phase units, you have to ensure the phases are sequenced correctly. Get it wrong, and you'll have motors spinning backward.

Verify Connections: Go back and check that every electrical terminal is torqued to spec. Loose connections are a serious fire hazard.

With the electrical side cleared, turn your attention to the mechanicals. Check that the fan belt has the right amount of tension and give the blower wheel and fan blades a spin by hand. You want to feel for any resistance or obstruction.

Measuring and Adjusting System Performance

Okay, now it's time to power it up and start the real fine-tuning. This is where your diagnostic tools come out to measure the system's vital signs. The data you collect here tells the real story of how well everything is working together.

A huge part of this is optimizing all the settings and components to improve HVAC efficiency and lower energy bills, locking in long-term savings for the client.

Key Takeaway: Document every single reading you take during commissioning. This baseline data is gold for future service calls. It lets technicians see exactly how the system’s performance has changed over time, making troubleshooting much faster.

You’ll be focusing on a few key measurements:

Refrigerant Pressures: Get your gauges on and compare the suction and liquid line pressures against the manufacturer’s performance chart for the current indoor and outdoor temps.

Amperage Draw: Measure the amp draw on the compressor and fan motors. You need to confirm they are running within their rated limits and not overworking.

Temperature Split: Check the temperature difference between the return air going in and the supply air coming out. A healthy split is typically around 18-22°F.

Final Controls and Safety Checks

The last piece of the puzzle is testing every single operational mode and safety control. Cycle the system through cooling, heating (if it’s a heat pump), and fan-only modes right from the thermostat. Make sure it responds exactly as it should.

Finally, test all the safety switches—like the high-pressure and low-pressure cutouts. You need to be 100% certain they will protect the equipment if something goes wrong.

This final verification ensures the system isn't just running, but running safely and smartly. It’s the official stamp of a professional job, one that contributes to the roughly 1.622 billion installed AC units keeping the world cool. You can discover more insights about global air conditioning trends on worldpopulationreview.com.

Common Questions About Commercial AC Installation

Even the most detailed installation plan can't cover everything. Questions always pop up, and getting clear answers upfront is the best way to keep a project on track and ensure you end up with a system that performs for years. Let’s tackle some of the most common things people ask.

How Long Does a Commercial AC Unit Installation Take

The timeline for a commercial install can really vary. If we're doing a straightforward rooftop unit swap on a small retail spot, we can often get it done in a single day.

But for a bigger project, like a full system install for a large office building with brand new ductwork and electrical, you could be looking at a week or more.

A few things can affect the schedule:

Permit Approvals: Sometimes, waiting on the local building department can add unexpected delays before we can even start.

Equipment and Crane Availability: Getting the unit delivered and scheduling a crane for a rooftop lift takes careful coordination.

Weather Conditions: You can't safely work on a roof in heavy rain or high winds, so bad weather can force us to reschedule.

Solid, realistic planning is the best way to minimize how much the installation disrupts your business.

What Are the Most Common Installation Mistakes

I've seen it all over the years, and three mistakes cause more headaches and system failures than anything else. Getting these right is non-negotiable.

First up is incorrect unit sizing. A unit that's too big will constantly turn on and off—what we call short-cycling—and it will never properly dehumidify the air. On the flip side, an undersized unit will run all day long and still never hit the temperature you set on the thermostat.

The second huge mistake is skipping a deep vacuum on the refrigerant lines to get them below 500 microns. If you leave moisture in the lines, it mixes with the refrigerant and creates corrosive acids that literally eat the system from the inside out.

Finally, there's improper refrigerant charging. Nothing will kill a compressor faster. Whether it's undercharged or overcharged, the system will run poorly and is at a huge risk for a total meltdown.

Key Insight: These aren't just technical details; they're the foundation of a good installation. Getting the size, vacuum, and charge right is the difference between a system that lasts 15 years and one that needs a new compressor in two.

What Maintenance Is Needed After a New AC Installation

Your investment doesn't stop once the new unit is up and running. To protect it, you need to stay on top of maintenance. The absolute most important job is changing the air filters every one to three months, depending on how dusty your environment is. Clogged filters choke off the airflow, which puts a massive strain on the system and sends your energy bills through the roof.

Beyond filters, you need to get a professional service check at least once a year. A good technician will clean the evaporator and condenser coils, check the refrigerant levels, inspect and tighten all electrical connections, and make sure the condensate drain is clear. This kind of proactive care is even more important in demanding spaces; you can read more about why regular HVAC service is critical in food service settings.

This simple routine keeps your new system running like it should and helps us catch small issues before they blow up into expensive emergencies.

For commercial HVAC and refrigeration services that prioritize professional operation and transparent communication, trust the experts. Putnam Mechanical LLC has the experience to ensure your new AC installation is done right the first time. Visit us at https://pmechanicalfl.com to schedule a consultation.

_edited%20copy.png)