Emergency Commercial Refrigeration Repair Guide

- Putnam Mechanical

- Aug 15, 2025

- 13 min read

That moment of panic is all too familiar. The walk-in freezer alarm is screaming, or a display case feels strangely warm to the touch. Your immediate response in these first few minutes is what separates a minor hiccup from a major financial disaster.

Having a solid plan for emergency commercial refrigeration repair isn't just about calling a technician—it's about controlling the chaos to protect your inventory and ensure everyone's safety.

Your First Moves During a Refrigeration Crisis

When a commercial refrigeration unit goes down, the clock starts ticking. The actions you take in that first hour can mean the difference between saving your product and watching it spoil. Instead of panicking, it's time to shift your focus to three key areas: assessing the situation, preserving your inventory, and gathering the right information.

First and foremost, think safety. If you smell anything unusual or see smoke, get everyone out of the immediate area. If it’s safe to do so, cut the power at the circuit breaker.

Once the scene is secure, start your assessment. Jot down any specific symptoms you notice.

Listen closely: Is the compressor making a new clanking sound? Is there a loud, persistent buzzing?

Look for error codes: Most modern units have a digital thermostat that will display error codes. Snap a quick photo of it—this is gold for a technician.

Check the physical state: Do you see excessive frost building up on the evaporator coils? Is there water pooling on the floor?

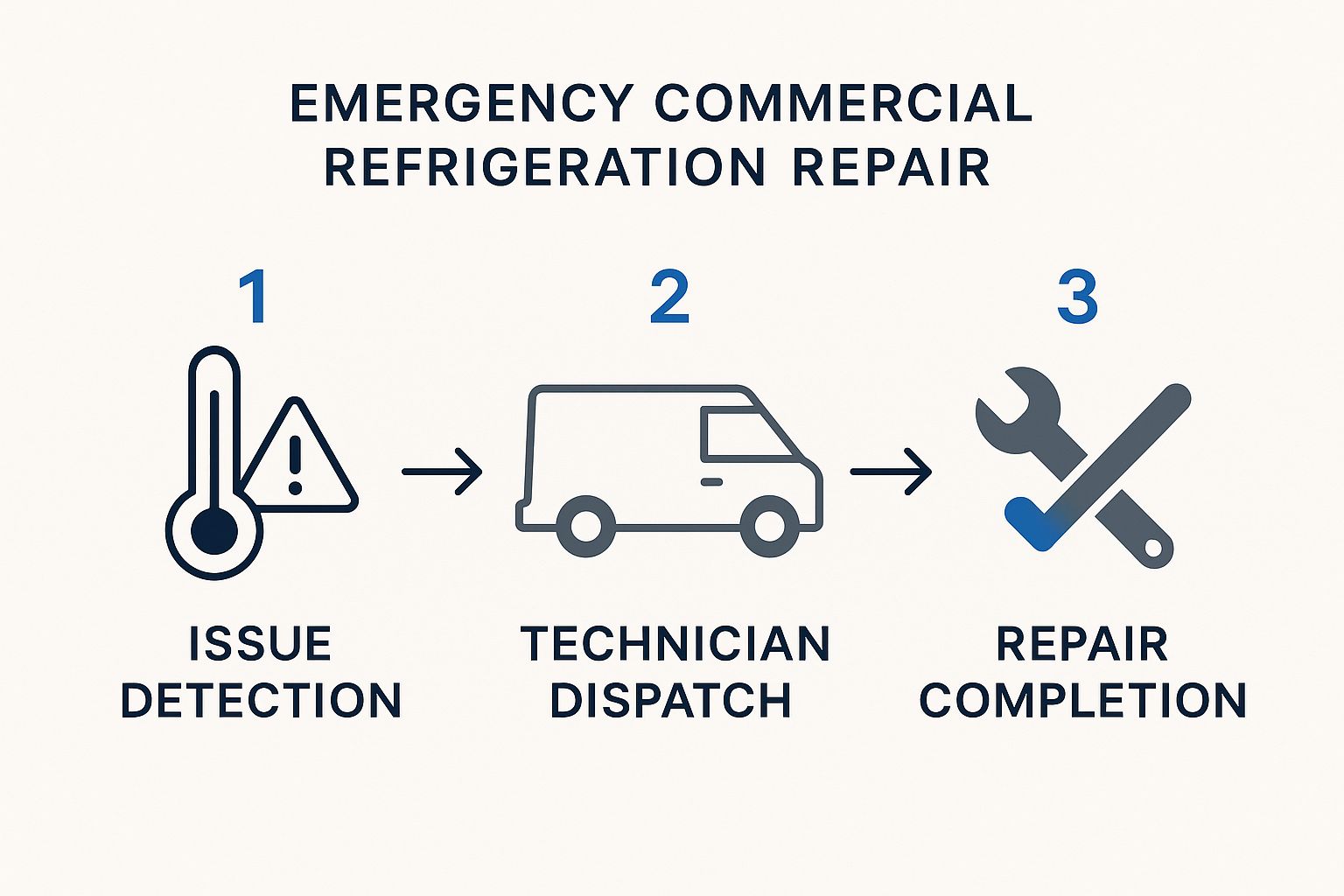

This simple process helps you move from detecting the problem to getting it resolved with speed and efficiency. The goal is to get your equipment back up and running as quickly as possible to protect your assets.

Protecting Your Assets and Preparing for Help

With that initial information in hand, your next move is all about protecting your inventory. Keep the unit's doors shut. Don't peek. Every time you open it, you lose precious cold air.

A well-sealed walk-in freezer can often hold a safe temperature for several hours even when it's not running, but you can't rely on that alone. You need a backup plan, whether that means moving product to another on-site unit or having a refrigerated truck on standby.

A proactive approach is non-negotiable. Waiting for the temperature to climb before you act is a recipe for serious loss. Your job is to stabilize the situation before a technician even walks through the door.

While knowing how to respond to an emergency is critical, preventing one in the first place is always the better option. Regular, consistent upkeep is the single most effective way to sidestep these surprise breakdowns.

We put together a practical guide on how to keep your commercial refrigerator running at peak performance that’s full of maintenance tips.

Neglecting upkeep leads to more than just spoiled food. Malfunctioning refrigeration systems are notorious energy hogs. Dirty coils and worn-out parts force the unit to work overtime, which sends your utility bills soaring. When you have all this information ready, you can give the technician clear, actionable details when you call for that emergency commercial refrigeration repair.

Refrigeration Failure Immediate Action Checklist

The moment you discover a problem, every action matters. This checklist is designed to guide you through those critical first steps, helping you minimize inventory loss and ensure a safe environment while you wait for professional help.

Priority Action | Key Objective | Critical Details to Note |

|---|---|---|

Ensure Scene Safety | Prevent injury or further equipment damage. | Check for smoke, strange odors, or sparking. If present, evacuate the area and cut power at the breaker if safe. |

Document Symptoms | Provide the technician with vital diagnostic information. | Take a photo of any error codes. Record any unusual noises (clanking, buzzing) and their location. Note any leaks. |

Preserve Inventory | Minimize product loss by retaining cold air. | Keep all doors and lids securely closed. Avoid opening the unit for any reason. |

Prepare Backup Storage | Create a contingency plan for your temperature-sensitive products. | Identify other on-site cold storage. If none, have contact info for a refrigerated truck rental ready. |

Contact a Technician | Get professional help on the way as soon as possible. | Provide the unit’s make/model, the error code, and a clear description of the symptoms you've observed. |

Following these steps methodically turns a chaotic situation into a managed response, setting the stage for a faster and more effective repair.

Decoding Common Refrigeration Failure Symptoms

Is that reach-in cooler just having an off day, or is its compressor about to give out? Knowing the difference between a minor quirk and a critical symptom can save you thousands in spoiled inventory and emergency repair bills. Catching the early warning signs of trouble is the first, and most important, step.

Your equipment almost always tells you something is wrong long before it completely shuts down. You just have to know what you’re looking and listening for. Ignoring these signs is like ignoring the check engine light in your car—the problem rarely goes away on its own and usually gets a lot more expensive.

Temperature and Moisture Clues

The most obvious red flag is a unit that just isn’t cold enough. If your walk-in freezer is sitting at 15°F instead of its usual 0°F, you have a problem that needs immediate attention. But temperature issues can be a lot more subtle than that.

Keep an eye out for inconsistent cooling or moisture where it shouldn't be:

Excessive Condensation: Seeing "sweat" on the outside of a unit or around door seals means warm, moist air is getting inside. This is often caused by a worn-out gasket, which forces the unit to work overtime just to keep up.

Unusual Frost Buildup: A light dusting of frost is normal. Thick sheets of ice on the evaporator coils or on your products, however, point to a failing defrost system or a major airflow problem. That ice acts like an insulator, preventing the unit from actually cooling anything.

A perfect example is finding a puddle on the floor of your walk-in cooler. It's not just a slip hazard; it’s a classic sign of a clogged or frozen drain line. If you don't address it, that small puddle can lead to much bigger, more expensive problems down the road.

Providing a technician with specific observations is incredibly valuable. Saying "the freezer has a sheet of ice on the back wall" is far more useful than just saying "it's not working right." This detail helps them diagnose the issue faster, sometimes even before they arrive on-site.

Sounds and Smells You Cannot Ignore

Your ears and nose are surprisingly powerful diagnostic tools. Commercial refrigeration units have a typical hum and rhythm. Any change from that baseline is worth a closer look.

For instance, a compressor that used to cycle on and off every 20 minutes but now runs nonstop is a huge warning sign. This constant cycling means the system is struggling to reach its target temperature, which could signal anything from a refrigerant leak to dirty condenser coils. For more tips on pinpointing issues, our guide on recognizing AC repair signs shares some great insights that apply to refrigeration, too.

Listen for these specific sounds:

Loud Grinding or Squealing: These noises usually mean the motor bearings in your evaporator or condenser fans are failing.

Clicking or Buzzing: A fast, repeated clicking can point to a bad compressor relay that’s trying and failing to start the motor.

And never, ever ignore strange odors—especially a burnt smell. This could be an overheating motor or an electrical short, which is both a mechanical failure and a serious fire hazard. By paying attention to these symptoms, you can catch problems early and turn a potential catastrophe into a manageable repair.

Choosing the Right Emergency Repair Partner

When a walk-in freezer gives out at 9 PM on a Saturday, you don’t have time to sift through online reviews. You need help, and you need it fast. The smartest thing any restaurant or facility manager can do is choose their emergency repair partner before a crisis hits. Having a trusted, vetted company on speed dial is what turns a full-blown disaster into a manageable problem.

This isn’t just about finding a company that answers the phone 24/7. It's about finding a team that shows up fast and gets the job done right when your inventory is on the line. The commercial refrigeration repair market is ballooning—it's expected to hit $25.8 billion by 2033—which means you have more options than ever, but it also means you have to be pickier about who you trust.

Beyond 24/7 Availability

True emergency service is about a lot more than just being open all hours. When you're vetting a partner for emergency commercial refrigeration repair, you have to dig a little deeper to see what they’re really made of.

Start by asking about their guaranteed response time. A vague promise like "we'll get there as soon as we can" just won't cut it. You need a firm commitment. For a real emergency, a 2-4 hour arrival window is a reasonable standard to expect.

Next, get into the details about their technicians.

Certifications: Are their techs EPA 608 certified? This isn't just a nice-to-have; it's required for legally and safely handling refrigerants.

Experience: Have they worked on your specific equipment before? A tech who knows their way around a True reach-in or a complex walk-in system is going to solve your problem much faster.

Parts on Hand: Ask about their on-van parts inventory. A well-stocked truck often means the difference between a first-time fix and waiting a day for a part to be ordered.

These questions help you separate the true specialists from the general handymen.

Evaluating a Potential Partner

Once you have a short list, it’s time to think about the business side of things. Look for a company that’s transparent with its pricing. You shouldn’t have to worry about hidden fees or surprise upcharges in the middle of a crisis. A good partner will be upfront about their service call fees and labor rates.

Don't underestimate the power of going local. A company that's part of your community knows the area, understands the urgency, and delivers a level of personal service that big national chains just can't match.

Finally, ask for references—specifically from other businesses like yours. Talking to another restaurant owner who has been in your shoes and relied on that company for an emergency repair gives you real-world insight that a website just can't provide. Doing this homework now ensures that when you make that urgent call, you're dialing a proven partner, not just taking a gamble. For a deeper look, our guide on why local HVAC contractors often beat national chains offers some great perspectives.

Managing the Repair Process and Unexpected Costs

When the technician arrives for an emergency repair, it's a huge relief. But it also kicks off a critical decision-making process. Understanding what comes next helps you stay in control of the situation and, more importantly, the final bill. The goal is to get from diagnosis to a working unit without any costly surprises.

A true professional won’t just fix the obvious symptom you called about. They'll start with a thorough diagnostic, digging deep to find the root cause. This means checking refrigerant levels, testing electrical components like relays and capacitors, and inspecting the compressor and fan motors.

Once they’ve pinpointed the problem, they should hand you a clear, itemized quote. This is your moment to ask questions and get a complete picture of the work before giving the green light.

Decoding the Repair Quote

A good repair quote is more than just a number at the bottom of a page; it’s a full breakdown of the job. It should clearly separate the costs for parts and labor. If you see a vague line item like "refrigeration repair," push for more detail.

You need to know exactly which parts are being swapped out and why. For example, a quote should specify "replace faulty condenser fan motor," not just "fix cooling issue." It should also spell out the warranty on both the new parts and the technician's labor. A reputable company always stands behind its work.

Don't be shy about asking the technician to walk you through their reasoning. A good tech can explain why a part failed and what the fix involves in simple terms. This conversation is a great way to gauge their expertise and build trust.

Never authorize a repair based on a verbal quote alone. Always insist on a written estimate that details every single charge. This document protects you from surprise fees and is crucial for your own records, especially if you need to make an insurance claim.

The Big Decision: Repair or Replace?

Sometimes, the diagnosis presents a tough choice. If you’re looking at a major repair, like a compressor replacement on an older unit, you have to weigh that cost against replacing the whole system. This is a significant financial decision, and it shouldn't be made lightly.

A helpful rule of thumb is the "50% rule." If the repair cost is more than half the price of a new, comparable unit, replacement is often the smarter long-term investment. Here's what to consider:

Age of the Unit: Most commercial refrigeration systems last about 10-15 years. Pouring a lot of money into an old system can start a frustrating cycle of one repair after another.

Energy Efficiency: A new unit is almost guaranteed to be more energy-efficient. Those savings on your monthly utility bills can help offset the upfront cost over time.

Frequency of Repairs: Is this the first time you've called for service in the past year, or are you on a first-name basis with the repair company? Frequent breakdowns are a huge red flag that the unit is on its last legs.

Making this call under pressure is never easy. To help you prepare, our guide on what to expect during a commercial refrigeration unit replacement offers some great insights. By carefully managing this process, you can make a confident, cost-effective decision that serves your business now and in the future.

From Reactive Repairs to Proactive Maintenance

An emergency commercial refrigeration repair is more than just an inconvenience—it’s a costly, high-stress event that can bring your operations to a grinding halt. The best way to handle a crisis is to keep it from happening in the first place. This means shifting your mindset from reactive to proactive, turning your equipment from a potential liability into an asset you can count on.

This change starts with your own team. You don't need to turn your staff into technicians, but you can build simple, consistent habits into their daily, weekly, and monthly routines. These small actions are surprisingly effective at catching minor issues before they spiral into a full-blown system failure.

Building Your In-House Maintenance Checklist

You can delegate a few simple checks to your team that will dramatically extend the life of your equipment. These tasks are quick and straightforward, but their cumulative impact is massive.

Daily Checks: This is just a quick visual scan. Staff can ensure doors are sealing properly, listen for any new or unusual noises, and confirm that digital temperature readouts are where they should be.

Weekly Tasks: Dedicate just ten minutes to some light cleaning. Wiping down door gaskets prevents mold and keeps the seal tight, while clearing debris from around the unit helps maintain proper airflow.

Monthly Actions: This involves a slightly deeper clean, focusing on the condenser coils. These coils are magnets for dust and grease, and when they get clogged, they force the compressor to work overtime—a leading cause of failure.

For more detailed strategies, our article on how regular refrigeration maintenance can prevent major food loss offers a deeper dive. Consistent upkeep is your best defense against unexpected breakdowns.

Investing in regular, professional service isn't an expense; it's a strategic investment in operational continuity. A technician can spot underlying issues like worn bearings or subtle refrigerant leaks that your staff might miss, saving you from catastrophic failure and a much larger repair bill.

The Value of Professional Service Agreements

While your team’s daily checks are a great first line of defense, they can't replace the trained eye of a certified technician. Think of a professional service agreement as your best insurance policy against emergencies. Scheduled visits from a pro ensure your system is calibrated, cleaned, and thoroughly inspected for hidden points of failure.

This approach is becoming more critical as the industry grows. The commercial refrigeration market is projected to expand from $29.6 billion in 2025 to over $50.3 billion by 2032, driven by higher food safety standards and demand for energy efficiency. You can check out more about these commercial refrigeration market trends.

Modern tools like remote temperature monitoring can also act as an early warning system, sending an alert straight to your phone if a unit’s temperature starts to drift. By combining simple staff routines with professional oversight, you build a powerful defense that keeps your business running smoothly and profitably.

Have Questions? We Have Answers.

When your equipment suddenly fails, it’s natural to have a lot of questions. Time is of the essence, and getting clear, direct answers helps you make smart decisions when your inventory is on the line. Here are a few of the most common concerns we hear from business owners dealing with a refrigeration emergency.

What Kind of Response Time Can I Expect for an Emergency Call?

For a real emergency where you risk losing high-value products, you should expect a quality service provider to be at your door within 2-4 hours. Of course, this can shift a bit depending on your location, traffic, and what time you call.

This is where having a service contract really pays off. It often gives you priority status, bumping your call to the front of the line during busy times or after hours. When you're looking for a repair partner, always ask them point-blank what their guaranteed emergency response time is.

What Is the Single Most Common Cause of Refrigeration Failure?

While a lot of things can go wrong, one of the most frequent—and preventable—causes we see is a dirty condenser coil. When those coils get clogged with dust, grease, and grime, the system can't get rid of heat properly.

This forces the compressor to work overtime just to keep things cool. The result? Sky-high energy bills, overheating, and eventually, a total system breakdown. Simply cleaning the coils regularly is one of the best things you can do to prevent this exact problem.

Understanding the root cause helps shift the focus from just fixing the immediate issue to preventing future breakdowns. A simple task like routine coil cleaning can save you thousands in emergency repair costs and lost product down the road.

Should I Repair My Old Unit or Just Replace It?

That's the big question, and it really comes down to three things: the unit's age, how much the repair will cost, and its overall energy efficiency. A good rule of thumb many of us in the industry use is the "50% rule."

If a repair quote is more than 50% of the cost of a new, comparable unit, it’s usually smarter to invest in a replacement.

Think about these points:

Unit Age: Most commercial units last about 10-15 years. If yours is getting close to that age—or has already passed it—and needs frequent attention, a replacement is probably your best bet.

Ongoing Costs: A new, energy-efficient model will almost certainly save you money on future repair bills and your monthly utility costs.

Repair Frequency: If this is the second or third service call you’ve made in the last year, it's a strong sign the unit is on its last legs.

Weighing these factors will help you make a financially sound decision that will benefit your business for years to come.

When a refrigeration emergency strikes, you need a partner you can trust to respond quickly and effectively. At Putnam Mechanical LLC, we offer same-day emergency services across West Florida to get your business back up and running. Contact us for reliable and upfront service at https://pmechanicalfl.com.

Article created using [Outrank](https://outrank.so)

_edited%20copy.png)