Commercial Appliance Parts and Service Guide

- Aug 18, 2025

- 16 min read

When you're running a business in hospitality or food service, your commercial appliances are the heart of the operation. From replacement parts like motors and compressors to professional services like installation and maintenance, keeping this equipment running isn't just a chore—it’s what keeps your doors open. A proactive approach is everything.

Why Proactive Appliance Service Is Your Best Investment

Think of your business as a high-performance race car. The walk-in freezer, industrial oven, and ice machine? They're your engine, tires, and fuel system. If even one small part fails, you're pulled out of the race, losing customers and revenue with every passing minute.

This is exactly why a smart strategy for commercial appliance parts and service isn't just another expense. It's a foundational investment in the stability and success of your entire operation. This guide goes beyond the simple break-fix cycle. We’re digging into a complete system for managing your equipment, covering everything from sourcing the right parts to building a maintenance schedule that works.

The goal here is simple: to help you build a resilient business that sidesteps unexpected failures and runs at peak efficiency.

Before we dive deeper, let's look at the core strategies we'll be covering. Think of these as the pillars holding up a well-managed commercial kitchen.

Key Pillars of Commercial Appliance Management

Strategy Pillar | Primary Goal | Business Impact |

|---|---|---|

Component Sourcing | Access high-quality, OEM-spec parts quickly. | Reduces downtime and ensures reliable, long-lasting repairs. |

Proactive Maintenance | Identify and fix issues before they cause a failure. | Prevents costly emergency calls and extends equipment lifespan. |

Expert Installation | Ensure new equipment is set up for optimal performance. | Maximizes efficiency, lowers energy bills, and prevents early breakdowns. |

Emergency Response | Get back online fast when unexpected failures occur. | Minimizes revenue loss and protects inventory from spoilage. |

By mastering these four areas, you shift from reacting to problems to actively preventing them, which is where the real savings and peace of mind are found.

The True Cost of Equipment Failure

When a critical appliance breaks down, the repair bill is often the smallest part of the problem. The real costs stack up fast and can sting your business long after the equipment is back up and running.

These hidden costs often include:

Lost Revenue: Every hour your kitchen is down is an hour you're not making money. Simple as that.

Spoiled Inventory: A dead walk-in freezer can mean thousands of dollars in food tossed in the trash. You can learn more right here about how regular refrigeration maintenance can prevent major food loss.

Damaged Reputation: Unhappy customers don't just leave; they tell others. Negative reviews from a single bad night can deter new business for months.

Decreased Staff Morale: Nothing burns out a good team faster than the stress and chaos of constantly failing equipment.

A proactive service strategy is the only reliable way to get a handle on these variables. When you catch problems before they become emergencies, you turn an unpredictable liability into a manageable, budgeted part of your operations.

A Growing Industry Demands Reliability

The need for dependable equipment is only getting more intense. The global commercial kitchen appliances market is currently valued at around USD 98.56 billion and is expected to climb to USD 133.02 billion, growing at a rate of about 6.18% annually.

This growth, fueled largely by the hospitality sector, means more competition and higher customer expectations. Your equipment can't afford to fail. Partnering with a certified provider like Putnam Mechanical ensures your business is ready to meet this demand without missing a beat.

Choosing Between OEM and Aftermarket Parts

When a critical piece of your commercial equipment goes down, you’ve got a big decision to make. Do you go with an Original Equipment Manufacturer (OEM) part or an aftermarket one? It can feel like a tricky choice, but knowing the real-world trade-offs is the key to protecting your business from more downtime.

Think of it like getting a part for a high-performance car. The OEM part comes straight from the factory—it’s guaranteed to fit perfectly and perform exactly as it should. An aftermarket part is made by someone else; it might look the same and cost less, but you’re rolling the dice on quality.

This single choice affects your equipment's reliability, safety, and your bottom line. Making the right call on commercial appliance parts and service is what keeps your operation running like a well-oiled machine.

The Case for OEM Parts

OEM parts are the real deal—they're the exact same components your appliance was built with in the first place. You’re essentially getting a factory-certified duplicate of what you’re replacing. For most situations, choosing OEM is the safest and most reliable move.

There are some powerful reasons to stick with OEM:

Guaranteed Compatibility: These parts are engineered for your exact model. There’s no guesswork. This perfect fit ensures your equipment runs just like the manufacturer designed it to.

Superior Quality and Durability: OEM parts are built from the same tough materials and go through the same strict testing as the originals. That almost always means they last longer.

Warranty Protection: This one is huge. Using OEM parts is often required to keep your manufacturer's warranty intact. Slap in an aftermarket part, and you could void your coverage, leaving you on the hook for any future repair costs.

So, what’s the catch? It’s the price. OEM parts almost always cost more upfront. But what you’re really buying is peace of mind and predictable performance, which can save you a ton of money down the road by avoiding early failures and repeat service calls.

When to Consider Aftermarket Parts

Aftermarket parts are made by third-party companies, not the original manufacturer. Their biggest selling point is the lower price tag, which can be pretty appealing when you’re watching your budget. These parts are basically reverse-engineered to fit and work like their OEM cousins.

While they're often seen as the riskier option, there are times when a high-quality aftermarket part makes sense. For something non-critical—think a shelf, a knob, or a handle—an aftermarket part can save you money with very little risk to how the appliance actually functions.

The problem is, the aftermarket world is a bit like the Wild West. The quality can swing wildly from excellent to downright dangerous.

The core challenge with aftermarket parts is inconsistency. While some may perform just as well as OEM, others can fail quickly, cause damage to other components, or even pose a safety hazard. This is why partnering with a trusted service provider is so crucial.

Navigating the Risks of Aftermarket Components

The potential savings from aftermarket parts come with some serious risks that every business owner needs to think about. Making the wrong choice can create a much bigger, more expensive headache than the one you started with.

Here’s a breakdown of what can go wrong:

Imperfect Fit: A part that’s off by just a millimeter can cause vibrations, stress, and wear out other components in the system way too fast.

Inferior Materials: To keep their prices low, some aftermarket makers cut corners with cheaper materials that just can’t handle the heat of a commercial kitchen.

Voided Warranties: As we mentioned, installing a non-OEM part can kill your manufacturer's warranty on the spot.

No Guarantee: Unlike OEM parts, a lot of aftermarket components have a limited warranty or none at all. If it fails, you’re out of luck.

When it comes to the guts of your machine—like a compressor, a control board, or a heating element—the risk of using an aftermarket part just isn’t worth the savings. A failure there doesn't just mean another repair; it means serious downtime, lost sales, and a potentially massive repair bill. A professional commercial appliance parts and service provider like Putnam Mechanical can help you make the right call, ensuring you get a reliable fix without taking a gamble.

Understanding Your Commercial Appliance Service Options

Trying to figure out commercial appliance parts and service can feel overwhelming, but it really just comes down to four types of support. Each one has a specific job in keeping your business running smoothly, from the day a new machine arrives to the moment an old one quits without warning.

Think of these services as different tools in your operational toolbox. You wouldn't use a hammer for a screw, and you need the right service for the right situation. Getting this right protects your equipment, keeps everyone safe, and lets you focus on your business.

Professional Installation: Your First Line of Defense

Proper installation is so much more than just plugging something in. It's a specialized process that sets your equipment up for years of solid performance. A professional technician makes sure everything is calibrated correctly, hooked up to utilities safely, and follows all local codes.

This first step is non-negotiable for a few big reasons:

Warranty Protection: Most manufacturers will void a warranty if a certified pro doesn't handle the installation.

Safety and Compliance: Messing up gas lines or electrical connections isn't just a mistake; it's a serious hazard. Professionals make sure it's all done by the book.

Optimal Performance: A machine that's set up correctly from the start runs more efficiently, which means lower energy bills from day one.

Trying to save a few bucks by skipping a professional install is a gamble that almost never pays off. You're just asking for early breakdowns, wasted energy, and potential trouble with insurance if something goes wrong.

Diagnostic Repair: Getting You Back Online

When a piece of equipment goes down, you need more than a temporary patch—you need to know exactly what went wrong. Expert repair starts with a thorough diagnostic, where a technician hunts down the root cause of the problem, not just the obvious symptom.

This means testing components, checking for electrical faults, and getting a feel for the machine's history. A good service provider will walk you through the issue, explain your repair options (like choosing between OEM and aftermarket parts), and give you a clear quote before starting any work. This way, you know the problem is actually being solved for good.

Preventive Maintenance: A Strategic Investment

Preventive maintenance is your best weapon against surprise equipment failures. It’s like a regular check-up for your appliances, involving scheduled inspections, cleanings, and tune-ups designed to catch little problems before they turn into huge, expensive headaches.

This proactive approach to commercial appliance parts and service turns your maintenance from a reactive, unpredictable cost into a planned, budgeted investment. A smart maintenance plan keeps your gear running at its best, helps it last longer, and dramatically cuts down the risk of unexpected downtime.

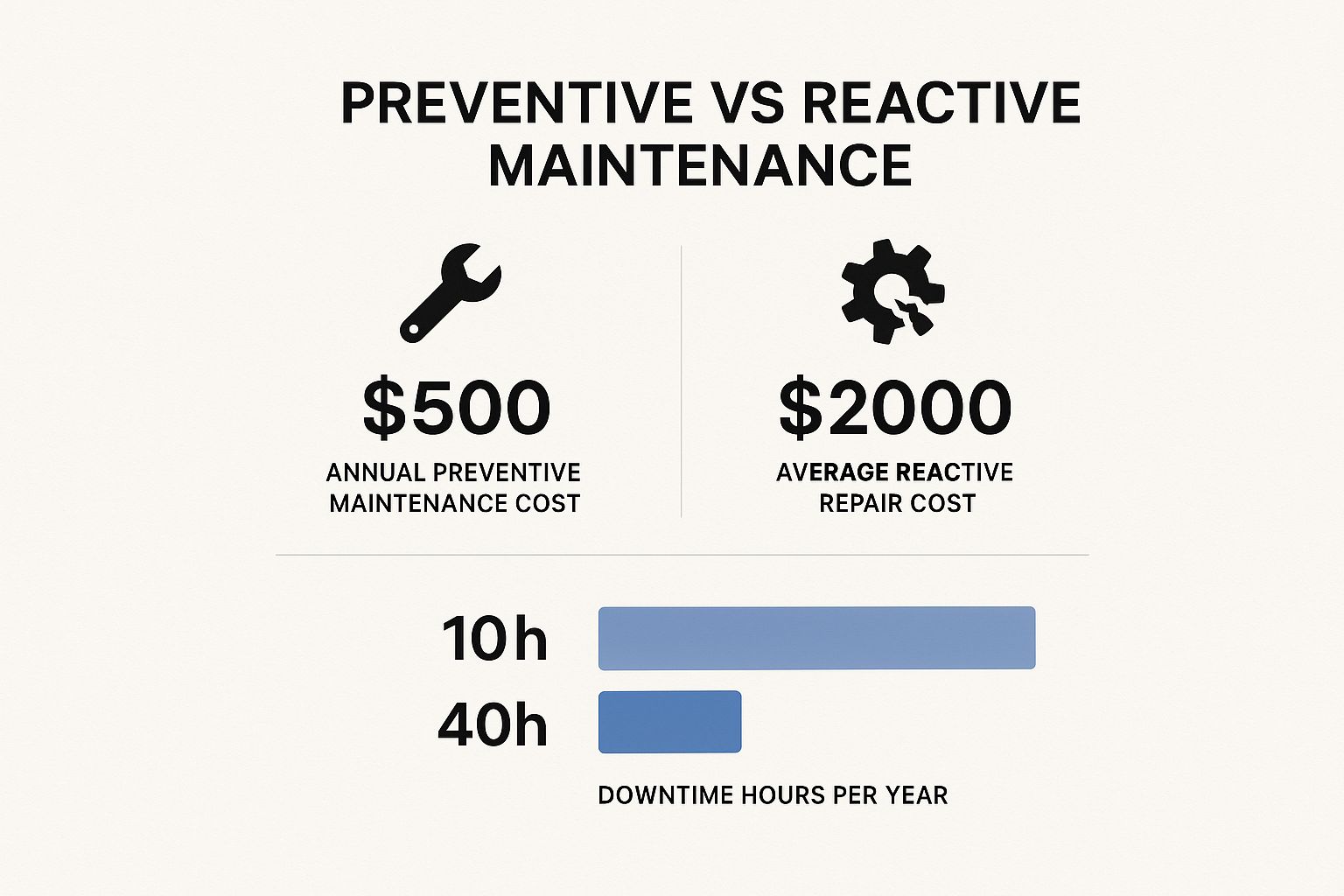

This image really drives home the financial and operational wins of investing in preventive care instead of just waiting for something to break.

The numbers don't lie. A small annual investment in proactive care can slash reactive repair costs by 75% and cut operational downtime by a similar amount.

This strategy is even more important with today's equipment. More businesses are using energy-efficient and smart, IoT-enabled appliances, which can reduce maintenance costs by up to 30%. These systems can often flag issues themselves, making preventive service even more effective.

To see how this works for specific systems, take a look at our guide on **commercial HVAC and refrigeration maintenance**.

Comparing Commercial Appliance Service Types

To make it even clearer, let's break down how these four services stack up against each other. Each has a distinct role, and understanding the differences helps you make smarter decisions for your business's bottom line and daily operations.

Service Type | When It's Needed | Primary Benefit | Cost Impact |

|---|---|---|---|

Installation | When you get new equipment. | Ensures safety, warranty, and peak performance from the start. | A one-time upfront investment that prevents future costs. |

Diagnostic Repair | When a machine breaks down or performs poorly. | Identifies the root cause for a lasting fix, not a patch. | A reactive cost, but a correct diagnosis prevents repeat issues. |

Preventive Maintenance | On a regular, scheduled basis. | Avoids major breakdowns and extends equipment life. | A predictable, planned expense that lowers overall repair costs. |

Emergency Response | During an unexpected, critical failure. | Minimizes downtime and prevents inventory loss. | The highest cost, used as a safety net for urgent situations. |

As you can see, investing in installation and preventive maintenance is a proactive strategy that directly reduces the need for costly reactive repairs and emergencies.

24/7 Emergency Response: Your Safety Net

Even with the best maintenance plan, emergencies happen. A walk-in freezer can die on a holiday weekend or a commercial oven can go out right in the middle of a dinner rush. These situations demand immediate action, and that’s where 24/7 emergency response is a lifesaver.

An emergency service isn't just about showing up fast; it's about having a trusted partner who gets the urgency and has the team and parts to fix the problem right away.

A reliable emergency provider is your business's safety net. They work to minimize the damage and get you back up and running as fast as humanly possible. That quick response can be the difference between a small hiccup and a huge financial loss from spoiled products and angry customers.

How to Select the Right Service Partner

Picking a partner for your commercial appliance parts and service needs is one of the biggest decisions you'll make for your business. This isn't just about finding the cheapest hourly rate. It’s about finding a team that acts like an extension of your own, protecting your investment and keeping your operation humming.

Think of it like hiring a key employee. You need someone with the right skills, a proven track record, and a genuine understanding of what you do. A general handyman might fix a leaky faucet at home, but they’re out of their depth trying to diagnose a complex issue in a commercial-grade refrigerator or your building's HVAC system.

Look for Specialized Expertise and Certifications

Your first filter should always be specialization. Commercial equipment is a different beast entirely from its residential cousins. It’s built to run hard, all day, every day. A technician needs to get the unique electrical, plumbing, and ventilation demands of a commercial space.

Look for providers whose technicians hold industry-recognized certifications. These aren't just pieces of paper; they're proof that a tech has gone through serious training and testing. It’s your assurance that they're up to speed on the latest tech and safety standards.

Evaluate Their Experience with Your Equipment

Not all commercial appliances are built the same. A technician who’s a wizard with pizza ovens might not know the first thing about your high-capacity ice machine. When you’re checking out potential partners, ask them directly about their hands-on experience with the exact brands and models you rely on.

A provider who already knows your equipment will find problems faster, get the right parts more efficiently, and make repairs that actually last. They know the common quirks and failure points of your specific gear, which cuts down on guesswork and costly downtime.

The real value of an experienced service partner isn't just fixing what's broken. It's their ability to see what might break next, turning reactive repairs into proactive solutions that save you money and headaches down the road.

This proactive approach is becoming more and more critical. The global market for appliance parts is projected to hit an incredible USD 255.1 billion. That growth is fueled by a smart shift toward repairing instead of replacing, which puts skilled service providers right at the center of the modern economy.

Assess Their Parts Inventory and Availability

A great technician is only as good as the parts they can get their hands on. When your equipment is down, every minute counts. You can’t afford to wait days for a critical component to ship from across the country. A top-notch service partner will have a well-stocked inventory of common OEM parts for the brands they service.

Ask them straight up about their parts strategy:

Do they keep common failure parts on their service trucks?

Do they have solid relationships with local suppliers for quick access?

What’s the typical turnaround for ordering a specialized part?

Their answers will tell you everything you need to know about how prepared they are to handle an emergency. The faster they get the part, the faster you’re back in business.

Demand Clear Communication and Transparency

Finally, a true service partner is an open book. That means upfront pricing with no hidden fees, clear explanations of the work that’s needed, and consistent updates from start to finish. Look for a company that uses modern tools to track jobs and scheduling so you’re always in the loop.

This is what separates the best from the rest. Choosing a local provider often makes a huge difference in communication and response times, too. For restaurants in particular, there's a good reason why local HVAC contractors often beat national chains. When you have a direct line to a team that knows your business and your equipment, you have a powerful ally in your corner.

Calculating the Real Cost of Equipment Downtime

When a critical piece of your kitchen equipment goes down, it’s natural to focus on the immediate repair bill. But that number? It’s just the tip of the iceberg. The real cost of that downtime goes way beyond the invoice your technician hands you, quietly draining your profits long after they’ve packed up their tools.

To really get why proactive commercial appliance parts and service is so crucial, you have to look past that surface-level expense and start calculating the hidden costs. Think of it as an operational blind spot—what you can’t see is often what hurts your business the most.

A Story of a Holiday Weekend Disaster

Picture this. You run a popular restaurant, it’s a packed holiday weekend, and every table is booked. Right in the middle of the Saturday dinner rush, your walk-in freezer gives out. The temperature inside starts creeping up, and that familiar sense of panic sets in.

This isn't just an inconvenience; it's a full-blown financial crisis unfolding in real-time. That repair bill is only the beginning of your problems. The true cost of this single failure is a cascade of losses that can cripple your business for weeks.

Breaking Down the True Cost of Downtime

Let's do the math on the real damage from that busted freezer. The initial repair might set you back a few hundred dollars, but the domino effect is far, far more expensive.

Here’s a simple way to see the full picture:

Lost Sales: With a key appliance out of commission, your kitchen grinds to a halt. You're forced to turn away hungry customers, cancel reservations, and close your doors early. That’s thousands of dollars in revenue vanishing in an instant.

Spoiled Inventory: A walk-in freezer holds a huge chunk of your inventory. If it fails, you could lose everything from prime cuts of steak to expensive seafood. This loss alone can easily make the cost of the repair look tiny.

Idle Staff Wages: Your team is on the clock and ready to work, but with the kitchen at a standstill, you're paying them to wait. Those wages become a direct, unproductive expense eating right into your margins.

Reputational Damage: This is the cost that really stings, and it lasts the longest. Angry online reviews from canceled reservations and a reputation for being unreliable can scare off new customers for months to come.

When you start quantifying these hidden expenses, the argument for investing in quality service becomes undeniable. That’s why so many businesses are putting a bigger focus on solid maintenance. In fact, the electrical appliances market, which includes commercial equipment, is projected to nearly double to USD 1,346.07 billion, showing just how much demand there is for reliable machinery.

When you add up lost sales, spoiled goods, paid-out wages, and long-term reputational harm, a single equipment failure can cost a business 5 to 10 times the price of the actual repair.

This perspective completely changes how you should look at maintenance. It’s no longer just another expense; it’s a strategic investment in uptime and profitability. A proactive plan for commercial appliance parts and service isn't about avoiding repair bills—it's about preventing a catastrophic financial event. For instance, understanding how ice machine efficiency can impact your bottom line is a perfect example of this principle in action.

Partnering with a provider like Putnam Mechanical LLC means you have a team dedicated to preventing these disasters before they happen, keeping your business profitable and protected.

Frequently Asked Questions About Appliance Service

When you're running a business, questions about commercial appliance parts and service come up all the time. You need clear, no-nonsense answers to protect your equipment and your bottom line. Let's tackle some of the most common questions we hear from business owners just like you.

When Should I Repair Versus Replace a Commercial Appliance?

This is the big one, isn't it? It’s tempting to squeeze every last bit of life out of an old machine, but sometimes, you're just throwing good money after bad. A solid guideline we often use is the 50% rule.

If a repair is going to cost you more than half the price of a brand-new, similar unit, it’s usually smarter to replace it.

But the price tag isn't the whole story. You also need to think about:

Age and History: Is the appliance getting up there in years? If it's near the end of its expected life and you've had to call for repairs more than once lately, a new model gives you reliability you can count on.

Energy Efficiency: Let's be honest—appliances from a decade ago are energy hogs compared to today's models. A new unit might cost more upfront, but it can seriously cut down your monthly utility bills.

Performance: Is your old unit keeping up? If it’s slow, struggling with demand, or just not doing its job well, a replacement is an investment in your business's productivity.

Thinking it through this way helps you make a strategic call that will benefit you for years to come, not just solve today's problem.

What Should a Good Service Contract Include?

Think of a service contract as your operational insurance policy. But not all of them are created equal. A great contract is all about clarity and security, so you know exactly what you’re getting when you need help. It should leave no room for guesswork.

A service contract worth its salt will clearly spell out these key things:

Guaranteed Response Times: It should state exactly how fast a technician will be on-site, with different times for regular calls versus true emergencies.

Preventive Maintenance Visits: The contract needs to detail how many PM visits are included each year and what, specifically, gets done during those check-ups.

Coverage Details: Look for straightforward language about what’s covered. Does it include both labor and parts? Are certain high-wear items excluded?

Emergency Provisions: The agreement has to define what counts as an "emergency" and explain the process for getting help after hours or on a weekend.

A well-written contract is a sign you're dealing with a professional commercial appliance parts and service provider. It shows they believe in being upfront and accountable, giving you confidence that your business is in good hands.

Are Aftermarket Parts a Safe Choice for Commercial Equipment?

The OEM (Original Equipment Manufacturer) versus aftermarket parts debate is always a hot topic, mostly because everyone wants to control costs. OEM parts are the gold standard—they’re made for your machine. But high-quality aftermarket parts can be a smart move for less critical components.

For something simple like a shelf bracket or a door handle, a reputable aftermarket part can save you money with almost no risk. The appliance will work just fine.

However, for the components that are the heart and soul of your machine—like compressors, motors, control boards, or heating elements—sticking with OEM is almost always the best decision. An ill-fitting or poorly made critical part can lead to a catastrophic failure, costing you way more than you saved.

Always weigh the potential savings against the risk. A cheap aftermarket part could void your warranty, damage other components, and lead to even more service calls down the road.

How Can My Team Help Extend Equipment Lifespan?

Your staff is on the front lines every day, and they can be your biggest asset in keeping your equipment running longer. Teaching them a few simple, consistent routines is one of the best ways to avoid emergency calls and unexpected downtime.

Focus on making these habits part of their daily workflow:

Daily Cleaning Protocols: Grease, dust, and food bits are the enemy. A regular cleaning of filters, coils, and surfaces prevents equipment from overheating and straining.

Proper Usage Training: Make sure everyone on the team knows how to operate the equipment the right way to avoid needless wear and tear.

Regular Visual Checks: Train staff to spot things like worn gaskets, frayed cords, or strange noises. Catching these little things early can prevent a huge breakdown.

Ensuring Clear Airflow: Just remind your team to keep the areas around refrigeration and HVAC units clear. Good airflow is critical for proper ventilation.

When your team handles the daily stuff and you have a professional handling the scheduled preventive maintenance, you’ve created a powerful system for equipment care. On a related note, you can learn more about caring for your other systems in our guide on how to get the most out of your heating and cooling system.

Ready to team up with a company that gives you straight answers and reliable service for your commercial appliances? Contact Putnam Mechanical LLC today and find out how our expert technicians can keep your business running at its best. Visit us at https://pmechanicalfl.com to schedule a consultation.

_edited%20copy.png)