A Guide to the Refrigeration Expansion Valve

- Putnam Mechanical

- Sep 2, 2025

- 13 min read

At the heart of any cooling system is a small but incredibly important part: the refrigeration expansion valve. This component is the main regulator for the entire system, controlling how much liquid refrigerant gets into the evaporator. Getting this flow just right is the key to performance, efficiency, and safety.

The Smart Gatekeeper of Your Cooling System

Think of the expansion valve as the intelligent gatekeeper for your refrigeration system. It works a bit like a high-precision nozzle on a hose, carefully managing both the volume and pressure of the refrigerant right before it enters the evaporator. This single component handles one of the most critical jobs in the whole refrigeration cycle.

By creating a sharp drop in pressure, the valve lets the high-pressure liquid refrigerant expand in a flash, turning it into a cold, low-pressure mist. This transformation is where the magic of cooling really happens, prepping the refrigerant to absorb as much heat as possible. Without this step, your system simply wouldn't be able to cool anything down.

Why This Control Is So Important

The valve’s job isn't just about making things cold—it's about doing it efficiently and safely. How well it meters the refrigerant has a huge impact on the system's overall health.

Boosting System Efficiency: By feeding the evaporator the perfect amount of refrigerant, the valve ensures it works at its best. This maximizes your cooling power while keeping energy waste to a minimum.

Protecting the Compressor: This is probably its most critical role. The valve prevents liquid refrigerant from getting back to the compressor. Liquid can't be compressed and will cause catastrophic failure, making the expansion valve an essential safeguard.

The idea of an automated valve was a game-changer for cooling technology. Before it came along, early systems needed someone to constantly adjust the refrigerant flow by hand—a process that was both inefficient and risky.

This small but mighty device has been a cornerstone of refrigeration for almost a century. The first patent for what we now know as the thermostatic expansion valve (TXV) was filed on August 24, 1927, by an inventor named Harry Thompson. He solved the nagging problem of how to protect compressors from liquid damage. You can learn more about the history of this critical invention and the impact it had.

How the Expansion Valve Powers the Cooling Cycle

To really get a feel for how a refrigeration expansion valve works, you have to follow the refrigerant on its journey through the system. It shows up at the valve's doorstep as a warm, high-pressure liquid, fresh from dumping heat in the condenser. At this stage, it’s full of potential, but it’s not nearly cold enough to do any actual cooling.

This is where the expansion valve steps in. It acts like a gatekeeper with a tiny, precise opening. Forcing all that liquid refrigerant through this small hole is the secret to the entire cooling process. As it squeezes through, the refrigerant experiences a sudden, massive drop in pressure.

Ever used a can of compressed air to clean a keyboard? You’ll notice the can gets incredibly cold after just a few seconds of spraying. That’s the exact same principle, a process called isenthalpic expansion. This abrupt pressure drop causes the liquid refrigerant to instantly expand and partially flash into vapor, transforming it into an ice-cold, low-pressure mist.

The Transformation from Liquid to Cold Mist

This change from a warm liquid to a frigid mist is where the magic really happens. The expansion valve’s main job is to perfectly control the amount of refrigerant flowing into the evaporator. This control creates the pressure drop needed for the refrigerant to boil and absorb heat from the surrounding space. It’s a simple but brilliant piece of engineering.

Now, this super-chilled mixture of liquid and vapor flows into the evaporator coils. Because it's so much colder than the air blowing across the coils, it starts soaking up heat like a sponge soaks up water.

Perfecting the Refrigerant Flow

But the valve's work isn't done yet. It has to constantly fine-tune the refrigerant flow to match the cooling demand, or what we call the "heat load." It's a delicate balancing act.

Too much refrigerant will flood the evaporator. The liquid won't have a chance to boil off completely, and it will get sent back to the compressor—a dangerous condition known as "liquid slugging" that can destroy it.

Too little refrigerant starves the evaporator. The system won't cool effectively and will have to work much harder, just wasting energy and driving up your bills.

The expansion valve's goal is to hit that sweet spot, making sure every last drop of liquid refrigerant boils into a gas right before leaving the evaporator. This maximizes cooling and ensures only vapor makes it back to the compressor.

A properly working valve is essential for the health and efficiency of any cooling system. For businesses that depend on keeping things cold, this small part is a massive asset. Keeping your entire system healthy, from the valve to the compressor, is a cornerstone of smart commercial HVAC management. By carefully managing this process, the expansion valve ensures your system delivers reliable and efficient cooling day in and day out.

Understanding Different Types of Expansion Valves

Not all expansion valves are created equal. Just like a mechanic needs different tools for different jobs, refrigeration systems rely on various valve designs to get precise control over refrigerant flow. Getting to know these types is the first step in diagnosing issues and really appreciating the engineering that goes into efficient cooling.

Each design takes a unique approach to metering refrigerant, and each comes with its own set of pros, cons, and best-use cases. The valve you choose—or the one in your existing system—directly impacts efficiency, complexity, and cost.

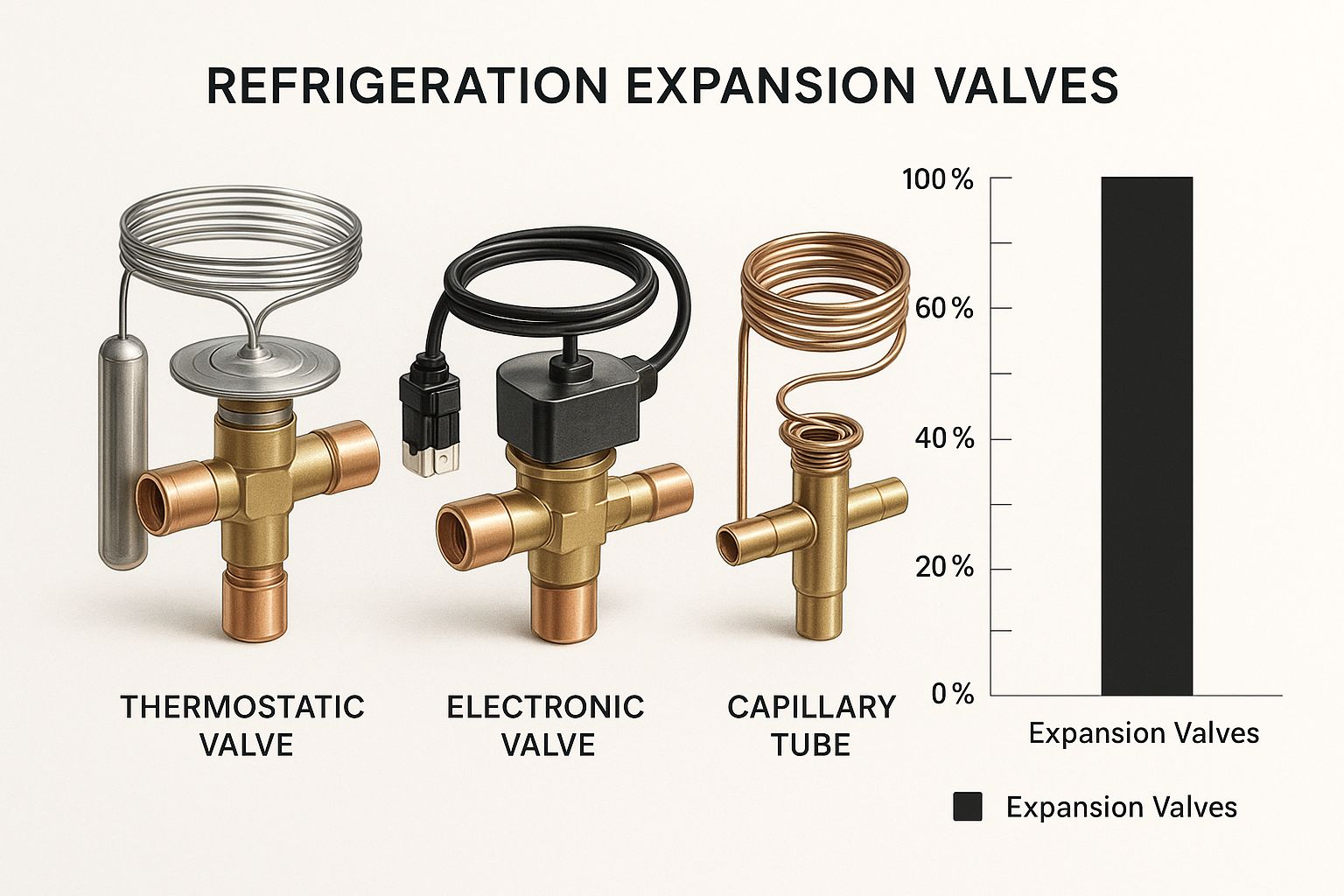

The three most common types you'll run into are Thermostatic Expansion Valves (TXVs), Electronic Expansion Valves (EEVs), and simple capillary tubes.

This graphic lays out the distinct designs of these common refrigeration expansion valve types.

From the bare-bones simplicity of a capillary tube to the sophisticated digital brain of an EEV, each valve is built for a specific purpose and level of performance.

The Workhorse: Thermostatic Expansion Valves (TXV)

The Thermostatic Expansion Valve (TXV) is without a doubt the most common type you'll find in commercial refrigeration and air conditioning. It's a mechanical marvel, operating with a sensing bulb that's clamped right onto the evaporator outlet. This bulb measures the refrigerant's temperature (or superheat) and automatically adjusts the valve opening to keep everything in perfect balance.

Its self-regulating nature is what makes the TXV so reliable and efficient across a wide range of conditions.

How it Works: The bulb contains its own fluid that expands or contracts with temperature changes. This movement applies pressure to a diaphragm inside the valve, pushing it open or letting it close. Simple and effective.

Best For: Systems with fluctuating heat loads, like commercial coolers or residential AC units, where demand is constantly changing throughout the day.

The Precision Player: Electronic Expansion Valves (EEV)

The Electronic Expansion Valve (EEV) brings refrigeration control into the modern age. Instead of a mechanical bulb, it uses a small motor run by a microprocessor. This setup allows for incredibly fine-tuned adjustments to refrigerant flow, all based on real-time data from multiple sensors.

While they are more complex, EEVs deliver far superior efficiency and control. In fact, studies show that systems using EEVs can be 15-25% more energy-efficient than those with traditional TXVs, especially when dealing with variable loads.

EEVs are the go-to choice for high-performance systems where squeezing out every bit of efficiency is the name of the game. They adapt to changing conditions in a split second—much faster than their mechanical cousins. Properly setting up and maintaining these advanced valves is a critical part of specialized commercial refrigeration work. To see how this fits into the bigger picture, you can learn more about **the role of comprehensive commercial HVAC services** in keeping these precise components in top shape.

The Simple Solution: Capillary Tubes

On the simplest end of the spectrum, we have the capillary tube. It's not really a "valve" in the traditional sense, but rather a long, skinny copper tube with a fixed diameter. It creates a constant pressure drop without any moving parts, which makes it extremely reliable and cheap to produce.

But that simplicity is also its biggest weakness. A capillary tube can't adjust to changes in heat load or ambient temperature. It's designed to work best under one specific operating condition and that's it.

How it Works: Its fixed length and tiny internal diameter act as a permanent restriction, metering a constant amount of refrigerant. No adjustments, no fuss.

Best For: Small, simple systems with stable operating conditions. Think domestic refrigerators, freezers, and window air conditioners.

To help you keep these straight, here's a quick comparison of the three main types.

Comparison of Common Refrigeration Expansion Valves

Valve Type | Control Method | Primary Advantage | Common Applications |

|---|---|---|---|

Thermostatic (TXV) | Mechanical (Sensing Bulb) | Reliable & adaptable to load changes | Commercial refrigeration, residential AC |

Electronic (EEV) | Digital (Microprocessor & Motor) | Highest efficiency & precise control | High-performance systems, chillers |

Capillary Tube | Fixed Orifice (No moving parts) | Extremely simple, reliable, & low cost | Domestic refrigerators, small freezers |

Choosing the right valve is all about matching the technology to the job. While a capillary tube is perfect for a mini-fridge, a large commercial walk-in cooler benefits immensely from the precision of an EEV.

How Expansion Valves Changed Modern Refrigeration

To really get why the refrigeration expansion valve is such a big deal, you have to imagine a world without it. Early refrigeration systems were clumsy, inefficient, and frankly, pretty dangerous. They were all about manual controls, which meant a technician had to stand there and constantly adjust the refrigerant flow by hand just to keep things running.

This wasn't just a hassle—it was a huge risk. The first refrigerants, like ammonia and sulfur dioxide, were toxic and flammable. One wrong move could cause a dangerous leak, making these systems completely unsuitable for public use. Refrigeration was stuck as a specialized, industrial process, a far cry from the reliable convenience we count on today.

The Dawn of a New Era in Cooling

The big breakthrough finally came in the 1920s with the invention of the automated thermostatic expansion valve (TXV). This small, self-regulating device completely changed the game. It got rid of the need for constant human supervision, which paved the way for systems that were both stable and dependable.

This innovation couldn't have come at a better time. It lined up perfectly with another major development—the creation of safer, non-toxic refrigerants like Freon. The combination of an automated valve and a safe refrigerant was the one-two punch that made modern refrigeration possible. It was the key to making cooling systems affordable, safe, and efficient enough for everyone.

This critical development and the widespread adoption of the thermostatic expansion valve happened during a truly transformative period. Its invention in 1927 coincided with a surge in refrigeration demand across brewing, meat-packing, and the new household appliance market. Learn more about the detailed history of air conditioning and refrigeration milestones.

From massive supermarkets that need consistent cooling to the air conditioner keeping your home comfortable, the legacy of the expansion valve is all around us. It turned a hazardous industrial process into an everyday necessity. It’s a bit of history that shows just how vital these parts are—and why professional [refrigeration services](https://www.pmechanicalfl.com/services) are so essential for keeping them in check. This single invention didn’t just improve a machine; it completely changed how we store food, cool buildings, and live our lives.

Troubleshooting Common Expansion Valve Failures

Even the most reliable refrigeration expansion valve will eventually run into trouble, and when it does, the entire system pays the price. A bad valve can act just like other system problems—say, a refrigerant leak or a tired compressor—which makes getting the diagnosis right the first time absolutely critical. For any service tech, learning to spot the unique symptoms of a failing valve is a non-negotiable skill.

Most expansion valve failures fall into one of three buckets: it's stuck wide open, it's jammed shut, or it’s erratically “hunting” for the right position. Each of these scenarios creates a distinct fingerprint of pressure readings and physical symptoms. Once you know what to look for, you can zero in on the problem, saving time and avoiding needless parts swapping.

Diagnosing a Valve Stuck Open

When an expansion valve gets stuck in the open position, it's like a busted fire hydrant flooding the evaporator with too much refrigerant. The evaporator coil simply can't keep up and boil off all that liquid. This "flooding" condition can send raw liquid refrigerant straight back to the compressor—a surefire way to cause catastrophic damage.

Here are the dead giveaways of a valve that’s stuck open:

High Suction Pressure: With way too much refrigerant pouring into the low side, the suction pressure will be unusually high.

Low Superheat: Because the refrigerant can’t fully vaporize, the temperature at the evaporator outlet will be just a hair above its boiling point. Your superheat reading will be close to zero.

Compressor Sweating or Frosting: That cold, liquid refrigerant hitting the warm compressor will cause it to sweat heavily or even build up a layer of frost.

This is one of the most dangerous failure modes for a system. Liquid slugging can obliterate compressor valves and bearings in no time.

Identifying a Valve Stuck Closed or Restricted

The flip side of the coin is a valve that’s stuck shut or severely clogged, which starves the evaporator of refrigerant. This is often caused by debris, wax, or moisture that’s frozen solid right at the valve's tiny opening. Without enough refrigerant, the system’s cooling capacity tanks, and the compressor is forced to work overtime under terrible conditions.

Keep an eye out for these tell-tale signs:

Low Suction Pressure: A starved evaporator will pull down into a deep vacuum or show very low suction pressure on your gauges.

High Superheat: With barely any liquid to boil off, the small amount of vapor that does get through becomes super-heated, leading to sky-high superheat values.

Short Cycling: The compressor will likely kick on and off repeatedly as the low-pressure safety switch does its job and trips the system.

Differentiating between a restricted valve and a low refrigerant charge is critical. Both can present with low suction pressure, but a system with a restricted valve will show high superheat, whereas a low-charge system often has both low superheat and low subcooling.

What Is Valve Hunting?

Sometimes a valve isn’t stuck in one position but is bouncing wildly between open and closed. This erratic behavior is called "hunting," and it causes massive swings in suction pressure and superheat. The system can never find a stable operating point, which kills efficiency and puts a ton of unnecessary strain on the compressor.

Hunting can be triggered by a few things, like a valve that’s oversized for the job, a sensing bulb that isn't mounted correctly, or a bulb that has lost its thermal charge.

Figuring out which issue you're facing is key to getting the system back to stable, efficient operation. The guide below can help you connect the dots between what you're seeing in the field and what might be happening with the valve.

Expansion Valve Troubleshooting Guide

Use this table as a quick reference to link common system symptoms to potential expansion valve issues and rule out other possibilities.

Symptom | Potential Valve Issue | Other Possible Causes |

|---|---|---|

Low Suction, High Superheat | Valve Stuck Closed/Restricted | Clogged filter-drier, low refrigerant charge |

High Suction, Low Superheat | Valve Stuck Open | Oversized valve, incorrect bulb placement |

Fluctuating Pressures | Valve Hunting | Improper bulb contact, loss of bulb charge |

Diagnosing these issues correctly not only fixes the immediate problem but also prevents future component failures. A methodical approach, guided by your gauges and an understanding of these failure modes, will always lead you to the right solution.

Getting Installation and Maintenance Right

Proper installation and routine maintenance are what make or break the long-term reliability of any refrigeration expansion valve. An ounce of prevention here is truly worth a pound of cure, helping you sidestep those frustrating callbacks and surprise system failures down the road. Even a top-of-the-line valve will let you down if it’s not installed with care.

One of the details that gets overlooked far too often is the placement of the thermostatic sensing bulb. It absolutely must have firm, clean contact with the suction line to get an accurate read on the refrigerant temperature. Get this wrong, and you'll see the valve "hunting" for the right setting or, even worse, flooding the compressor. Always stick to the manufacturer's guidelines for positioning—which is usually at the 10 or 2 o’clock spot on horizontal lines.

Protecting the Valve and System

Your brazing technique is another critical piece of the puzzle during installation. It’s incredibly easy to overheat the valve body, which can permanently fry internal components like diaphragms and seals. You have to wrap the valve body with a wet rag or use a thermal heat-blocking paste to soak up that excess heat and protect its delicate guts from damage.

A clean and dry system is a reliable system. Before you even think about installing a new refrigeration expansion valve, make sure you put in a new filter-drier. Then, pull a proper vacuum to get all the moisture and non-condensables out of there—those are the things that cause corrosion and blockages.

Finally, proactive maintenance is what keeps that valve running efficiently for years. This isn't a "set it and forget it" part. Regular check-ins are vital for the health of the entire system.

Preventative Maintenance Checklist:

Verify Superheat: Every so often, check and tweak the superheat setting. You want to keep it in the manufacturer's sweet spot for the best performance.

Inspect for Leaks: Get in there and carefully check all connections for any signs of refrigerant leaks, paying close attention to flare fittings and brazed joints.

Check Insulation: Make sure the sensing bulb is properly insulated. If it's exposed, it will read the ambient air temperature and throw everything off.

Following these practices is just part of being a professional in this field. Consistent upkeep doesn't just make the valve last longer; it boosts the whole system's efficiency. To learn more about building a solid upkeep routine, check out our guide on effective [preventative maintenance programs](https://www.pmechanicalfl.com/copy-of-maintenance-programs).

Frequently Asked Questions

Even when you have a good handle on how expansion valves work, specific questions always pop up out in the field. Here are some straightforward, practical answers to the queries we hear most often from technicians and system owners.

How Do I Know if My Expansion Valve Is Bad?

A failing expansion valve will give you some clear warning signs. Keep an eye out for inconsistent cooling, a sudden frost buildup on the evaporator coils, or weird noises coming from a struggling compressor.

You might also see some strange pressure readings on your gauges—either way too high or way too low. These are classic symptoms of a valve that’s stuck open, shut, or just can't find the right balance.

Can a Refrigeration Expansion Valve Be Repaired?

For nearly all modern systems, the answer is a firm no. Most expansion valves are precision-engineered, sealed units. They're built to be replaced, not repaired on-site.

Trying to take one apart is a bad idea. You risk getting moisture or dirt into the refrigerant lines, which can cause much bigger headaches down the road, like a fried compressor. Swapping it out for a new one is always the safest and most reliable fix.

Superheat is the temperature that refrigerant vapor gains after it has completely finished boiling into a gas. Think of it as a safety buffer that ensures no liquid droplets make it back to the compressor.

What Is Superheat and Why Does It Matter?

Superheat is one of the most important measurements in any cooling system. For a thermostatic expansion valve (TXV), it's the key piece of information it uses to control how much refrigerant flows into the evaporator.

If your superheat is too low, the valve is letting in too much refrigerant, which could send liquid back to the compressor and cause serious damage. If it's too high, the system isn't getting enough refrigerant, leading to poor cooling and wasted energy. Nailing the correct superheat is everything for performance and protection. For more expert insights and HVAC tips, explore our comprehensive [P&M Mechanical blog](https://www.pmechanicalfl.com/blog).

At Putnam Mechanical LLC, we specialize in expert commercial HVAC and refrigeration services to keep your systems running at peak performance. If you're facing issues with your refrigeration expansion valve or any other component, contact us today for reliable, professional support.

_edited%20copy.png)